IFTLE has spent significant time discussing the lack of U.S.-based substrate manufacturing.

Although packages such as the ball-grid array (BGA) were invented by U.S. companies like Motorola, production capacity was all off-shored to Asia years ago. Having competent U.S. production capacity has always been part of the US reshoring program.

In IFTLE 513 we examined the IPC report “The IPC NA Advanced Packaging Ecosystem Gap Assessment” which is still a great resource for understanding this situation [link]

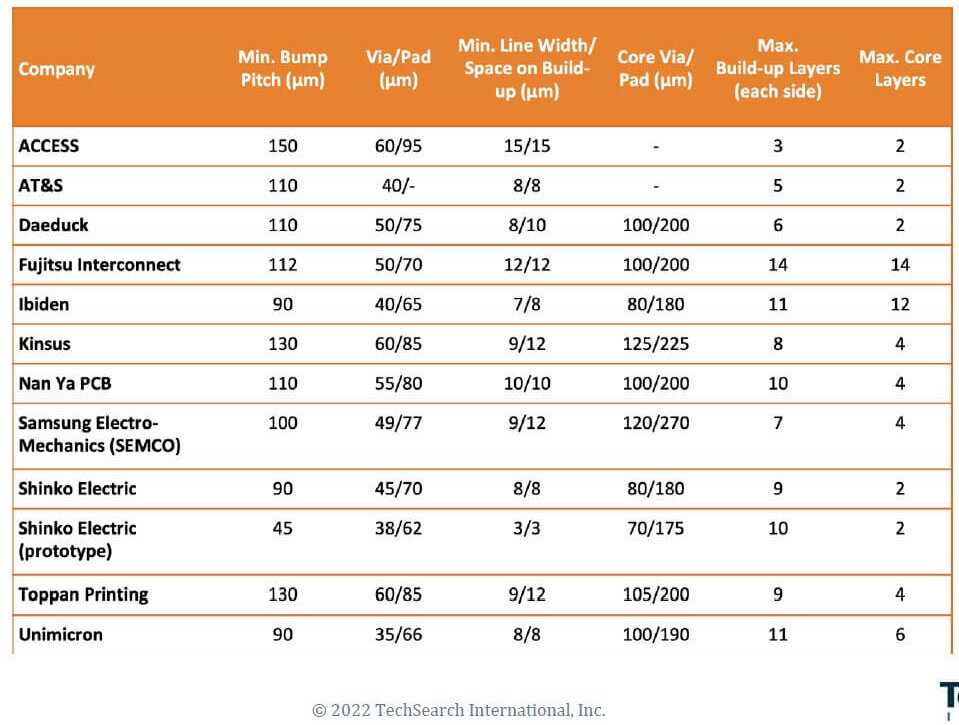

A quick look at the world’s major substrate suppliers confirms that none of them have U.S.-based manufacturing (Figure 1).

The Industrial Base Analysis and Sustainment Reshore Ecosystem for Secure Heterogeneous Advanced Packaging Electronics (IBAS RESHAPE) program, which outlined the advanced packaging technologies that we needed to put in place, had high-density build-up (HDBU) substrates called out front and center.

However, the IBAS RESHAPE program did not have to fund HDBU substrate manufacturing when it became clear that other Department of Defense (DoD) sources (namely the Defense Production Act Investment (DPAI) Program (Title III) would be used for such funding. That has finally happened over the past few months.

Calumet Electronics Corp.

In Nov 2023, the DoD announced an award of $39.9 million via the DPAI Title III program to Calumet Electronics Corporation to “…enhance capabilities to produce High-Density Build-Up (HDBU) substrates, which include High-Density Interconnect Printed Circuit Board (PrCB) cores and HDBU build-up layers.”

Dr. Laura Taylor-Kale, Assistant Secretary of Defense for Industrial Base Policy stated “These technologies are critical for modern weapons systems and will contribute to maintaining our warfighting edge over potential adversaries.”

The award will reportedly enable Calumet to scale up engineering, tooling, and manufacturing operations to establish domestic production capabilities for HDBU substrates. HDBU substrates and advanced packaging are critical enabling technologies for sixth-generation systems and applications, including for radar, electronic warfare, processing, and communications.

Calumet also received $7.5 million in incentives from the Michigan Economic Development Corporation via the Michigan Strategic Fund to support the company’s emerging capability to enable next-generation DoD technology in critical multifunction applications. The state provided additional tax and property incentives in its package.

The new 60,000-square-foot manufacturing facility, adjacent to its existing operations, will be the first of its kind in the United States, according to the Michigan Economic Development Corporation. The facility will include Class 1000 Clean rooms to expand organic substrate production for the nation, particularly as it relates to communication and electronic warfare.

Calumet, located in the upper peninsula of Michigan, was incorporated in 1968 and reportedly, supplies ~ 4MM standard PCB/yr.

GreenSource Fabrication

The Department of Defense announced an award of $46.2 million to GreenSource Fabrication

The award will enhance existing production capabilities at a manufacturing facility of state-of-the-art integrated circuits (IC) substrate, high-density interconnect (HDI) and ultra-high-density interconnect (UHDI), and advanced packaging.

Dr. Taylor-Kale noted that “Expanding domestic production capability for printed circuit boards and advanced packaging is necessary to avert a shortfall that would severely impair national defense capability.”

The award will enable GreenSource to scale up engineering, tooling, and manufacturing operations to establish a dedicated facility for IC substrate fabrication for a high-mix, low-volume offering of advanced interconnect solutions. These domestic production capabilities for HDI, UHDI, IC substrates, and advanced packaging are critical enabling technologies for sixth-generation systems and applications, including radar, electronic warfare, information processing, and communications.

In both these cases it would not be fair to expect state-of-the-art (SOTA) capability to be created instantaneously. One should fully expect 2-3 years of installation and qualification to truly develop processes that would be considered SOTA with today’s global production (see table above). Best of luck to Calumet and GreenSource, but to be frank, IFTLE would have been more comfortable if, in addition, we had gotten one of the major players listed in the above table to build capacity in the US.

For all the latest in advanced packaging stay linked to IFTLE……………..