2023 3D InCites Awards Winner Circle

The 2023 3D InCites Awards program recognized industry-wide contributions in the development of heterogeneous integration and 3D technologies. In 2021, we added two awards to recognize companies that demonstrate best practices in sustainable manufacturing efforts, as well as diversity equity and inclusion (DEI). Below are the winners of the 2023 Awards, selected by judges and online vote.

The Winner’s Circle

Sustainability Award:Tokyo Electron Limited

We are very much honored to be recognized as the leader in Sustainability. We are committed to working on corporate sustainability through our core business in order to help resolve issues and the development of industry and society, as well as the achievement of SDGs. We will continue to promote sustainability-focused management and pursue our corporate philosophy "to contribute to the development of a dream-inspiring society through our leading-edge technologies and reliable service and support.Yuji Ogino, Vice President, Corporate Sustainability Management

While all four finalists for the 2023 Sustainability Award — Henkel Corporation, SEMI, TSMC, and TEL —are all working to improve sustainability in the semiconductor industry, TEL stood out as the leader among them. According to the judges, TEL performed the best against the sustainability goals presented in its 2022 sustainability report, performing well in all categories. Specifically, the company progressed in waste reduction, energy conservation, water conservation, and identifying GHG used in their processes. While TEL accomplished this mainly by ramping up the use of renewable energy, its expected certification to science-based targets (SBT) in 2023 shows a commitment to further reductions. TEL also runs programs that reward innovative ideas from employees and encourage environmental responsibility throughout the supply chain.

SemiSister Award for DEI:Deca Technologies

It is a tremendous honor to receive the 2023 SemiSister Award for DEI. At Deca, our priority is innovation, and we believe diversity is key in driving that innovation. As a growing company, we recognize that the best time to establish practices for DEI is now, so that it is embedded in Deca's DNA. Thank you to our Deca family for continuously working to foster such an inclusive environment and to the committee for recognizing our efforts.Robin Davis, Director of Business Development

Similarly, the four finalists for the 2023 SemiSister Award for DEI — Deca, Dupont, Lam Research, and Soitec — should all be applauded for prioritizing DEI at their companies. However, as Margaret Kindling explained, “In previous years, the DEI award went to very large companies like Lam Research (2021) and AMD (2022) based on the publicly available information. This year, we based our selection not only on what has been achieved so far by a larger company but the possibility and growth mindset of a small company. Deca sets the example of what other small companies can and should strive for regarding diversity, equity, inclusion, and belonging.”

Device Manufacturer of the Year:Qorvo, Inc.

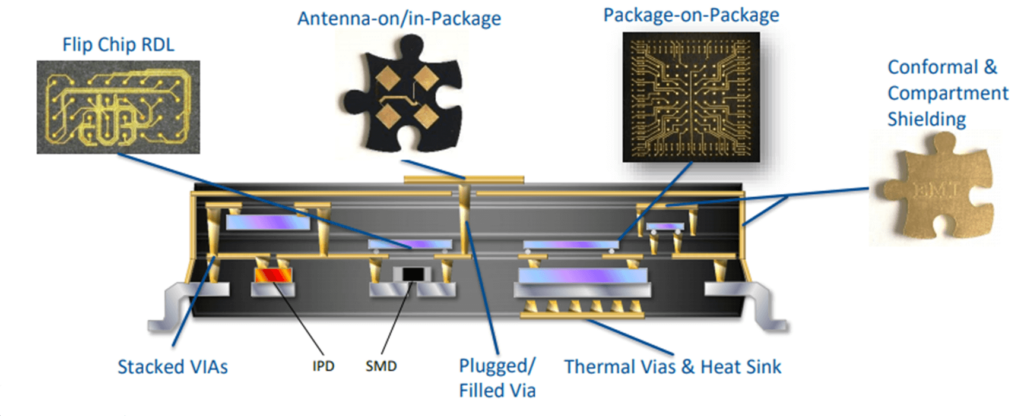

A newcomer to the 3D InCites Awards, this year’s Device Manufacturer of the Year Award goes to Qorvo for its Advanced State-of-the-Art RF Semiconductor Packaging Center. Qorvo® was selected by the U.S. government to create a State-of-the-Art (SOTA) Heterogeneous Integrated Packaging (SHIP) RF production and prototyping center in Richardson TX. Under the SHIP program, Qorvo is expanding its capabilities in Texas to create a SOTA facility that will design and deliver the highest levels of heterogeneous packaging integration.

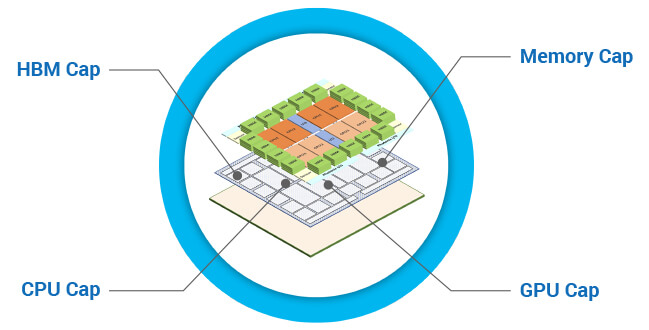

Device Technology of the Year:ASE VIPack™

As move further into the chiplets era, ASE’s VIPack™ is evolving, and delivering the technology advancements that enable us to be innovative, original, and imaginative. We feel honored and absolutely thrilled to receive the Device Technology of the Year award from 3DInCites, as it not only recognizes the value of VIPack™, but also the creativity of our teams to advance system capability and propel our industry forward.Yin Chang, Senior Vice President of Sales & Marketing

This is not ASE’s first 3D InCites award. In 2021, they were the first company to be presented with the 3D InCites Sustainability Award. This year, they are being acknowledged for their breakthrough scalable heterogeneous integration platform, the VIPack™, or as I like to call it – the Six Pack.

First introduced at the 2022 ECTC, ASE has been making a splash all year with VIPack™, designed to expand in alignment with industry roadmaps. It definitely caught the judges’ attention for its core technology pillars supported by a comprehensive and integrated co-design ecosystem. It provides solutions that support leading-edge high-performance computing (HPC), artificial intelligence (AI), machine learning (ML) and network applications, as well as optical interconnects.

Engineer of the Year (AT&S):Markus Leitgeb

I am very honored to be named 3D InCites Engineer of the Year. R&D is a team effort at AT&S and without the support of my excellent colleagues, this success would not have been possible. The innovative ECP® technology that we have developed is already creating new possibilities in the field of Advanced Packaging for our customers and we will continue to push the boundaries of technology. Thank you, 3D InCitesMarkus Leitgeb, Manager R&D – R&D Center Leoben

Advanced IC substrates are a critical area for meeting the next-generation requirements for heterogeneous integration and advanced packaging. As winner of the 2023 3D InCites Engineer of the Year award, Markus is recognized for his work developing AT&S‘ embedded component packaging (ECP®), and bringing it to the production level. He leads the R&D team for Micro Electronics in AT&S, which is developing new concepts for IC Substrates and Advanced Packaging Solutions. Markus joined AT&S in December 2000 after graduating from Leoben University, Austria. He was responsible for the evaluation and implementation of new testing methodologies (e.g. Drop Test) and the development of alternative manufacturing concepts for flexible interconnections as well as cavities. Markus has filed more than 100 patents and has published several papers in the field of PCBs and Packaging (2014 IPC APEX EXPO Best International Paper Award). Markus is an active member of iNEMI and in the Packaging Technologies subcommittee of ECTC.

Equipment Supplier of the Year:ClassOne Technology

Thank you to the 3D InCites community for this accolade. We’re honored to have been named Equipment Supplier of the Year. Receiving this award on our first nomination underscores the strides we’ve been making in building our installed base and collaborating with our customers to help enable their heterogeneous integration technologies and processes. We have many more irons in the fire that we’re excited to bring to fruition in the year ahead.Byron Exarcos, CEO

This is ClassOne’s first time being nominated for a 3D InCites Award. It’s only recently that the company has been on 3D InCites radar as a player in the advanced packaging and heterogeneous integration space. In 2022, ClassOne significantly broadened the heterogeneous integration capabilities of its Solstice™ single-wafer wet-processing platform to include electroplating and surface preparation (SP) processes. So now in addition to micropillar, high-aspect-ratio TSV, and RDL, surface prep processes like solvent strip, wet etch, metal lift-off, and single-wafer cleaning can all be integrated into one system. Moreover, furthering Solstice’s role as an enabling technology for HI, ClassOne and Fraunhofer ENAS announced a partnership to advance hybrid bonding capability for wafer-to-wafer and chip-to-wafer advanced packaging applications.

Herb Reiter Design Tool Provider of the Year:Xpeedic Technology, Inc.

Thank you from everyone at Xpeedic. We are grateful to our community for voting for us for the 3D InCites Herb Reiter Design Tool Provider Award. We are honored as a first-time nominee to be selected as the recipient and will continue working with our customers and ecosystem partners to tackle 3D IC and heterogeneous integration design challenges.Feng Ling, Founder and CEO

First-time 3D InCites Award nominee, Xpeedic was selected for its Metis platform, developed to address the signal/power integrity challenges arising from the advanced packaging for 2.5D/3DIC chiplet designs. Its multi-scale capability and capacity advantage enables unified EM simulation of die, interposer, and substrate without resorting to an error-prone cut-and-stitch approach used by legacy EDA tools. Its multi-mode option offers engineers a choice of speed and accuracy to cover design phases from architectural exploration to sign-off. Xpeedic has collaborated with ecosystem partners to qualify Metis in various mainstream advanced packaging technologies. Metis has been widely adopted by the leading IC companies in designing next-generation HPC and AI chips in the data center and automotive market.

Materials Supplier of the Year :Henkel Corporation

We are honored to be chosen as the material supplier of the year. This is a testament to the efforts of our global team and to our continuous investment in innovation and manufacturing to strengthen the portfolio of semiconductor packaging materials to serve our customers. Our sincere thanks to the 3DInCites community and the panel for bestowing this award to Henkel.Ram Trichur

Another first-time nominee, Henkel is being recognized for achieving several innovations in 2022 that address some of the most pressing issues in semiconductor packaging including high thermal requirements, transistor scaling, advanced Si node chip integration, and ongoing miniaturization. In the die-attach space, three new high-reliability materials were commercialized: a non-sintering high-thermal 30 W/m-K paste, an ultra-high-thermal 165 W/m-K pressureless sintering material, and a BOM simplification die-attach film for leadframe and laminate packages. In the flip chip protection arena, Henkel debuted a capillary underfill for leading-edge Si node flip chips that are now used in top-tier smartphones. Also, breakthrough active mold packaging work was conducted with LPKF Laser & Electronics AG using Henkel liquid encapsulants to achieve ultra-thin layers for laser-direct structuring.

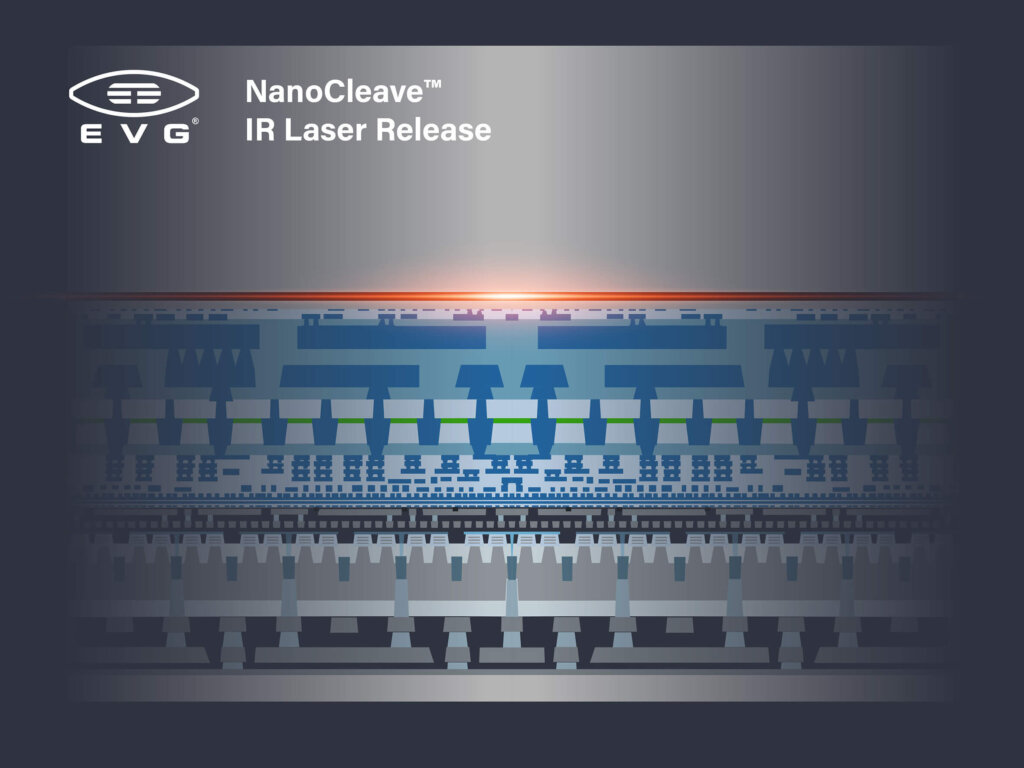

Process of the Year:EV Group (Nanocleave)

On behalf of EV Group, I wish to extend our sincerest thanks to the panel judges and 3DInCites readers for recognizing NanoCleave™ as this year’s 3DInCites Process of the Year. Our team worked very hard to develop this revolutionary IR laser release technology, and we look forward to partnering with our customers to realize their advanced device and packaging roadmaps with the help of NanoCleave.Paul Lindner, Executive Technology Director

EV Group is no stranger to the 3D InCites Awards Winner’s Circle. In 2013, the company won the 3D Manufacturing Equipment Category for its EV Group EVG850TB/DB XT temporary bond/debond solution. In 2015, they took home the equipment award for the GEMINI®FB XT automated fusion wafer bonder, and again in 2020 for the SmartView® NT3 face-to-face bond aligner. This is the first year time EVG wins Process of the year for NanoCleave, a revolutionary layer release technology for silicon that enables ultra-thin layer stacking for front-end processing, including advanced logic, memory, and power device formation, as well as advanced packaging.

It is a fully front-end-compatible layer release technology featuring an IR laser that can pass through silicon. Coupled with the use of specially formulated inorganic layers, this technology enables an IR laser-initiated release of any ultra-thin film or layer from silicon carriers with nanometer precision.

NanoCleave enables silicon wafer carriers in advanced packaging processes such as FOWLP using mold/reconstituted wafers and interposers for 3D-SICs. Its compatibility with high-temp processes also enables completely novel process flows for 3D IC and 3D sequential integration – enabling hybrid and fusion bonding of ultra-thin layers on silicon carriers, revolutionizing 3D/heterogeneous integration and material transfer in next-gen scaled transistor designs.

Startup of the Year :Saras Micro Devices

The entire Saras Micro Devices team is proud and honored to be the recipient of 3D InCites “Start-Up of the Year” award. We extend our deep appreciation to the judging panel and all who gave their voting support for this recognition. We’re excited about what we’ve accomplished and look forward to seeing the high-performance device packaging solutions our disruptive power delivery technology will enable.Ron Huemoeller, CEO, Saras Micro Devices

While the name, Saras Micro Devices may seem new to you, the members of the executive team are very recognizable. Ramakanth Alapati, Executive Chairman, is also Cbairman and CEO of YES. Previous roles included leading technology strategy and roadmaps at Amkor Technology, directing packaging product management and R&D at GlobalFoundries, and guiding the development and commercialization of double patterning & TSV technologies at Micron Technology. It’s no surprise that he tapped into his network to bring on board such advanced packaging experts as CEO, Ron Huemoeller, formally of Amkor Technologies and longtime member of IMAPS. Additionally, CTO Jon Greenwood held leadership positions at Los Alamos National Laboratory, Plexus, Globalfoundries, Micron, Amkor Technology, and Motorola; and CTO and Senior Fellow, Urmi Ray, Ph.D. brings 25 years of advanced packaging expertise from JCET, Qualcomm, and Lucent Technologies Bell Laboratories,

Saras Micro Devices is working to eliminate the power challenges of large HPC computing engines, AI, virtual reality, 5G and more with new panel-level power delivery technology. The company’s heterogeneous integration solutions are said to deliver substantially improved HPC performance per Watt, reduced design cycle times, and reduced 3D footprint through seamless co-design — all at a cost advantage.