I’ve had about a week to process, ponder, and reflect on all the information I absorbed last week at SEMICON West 2023. From the speakers at imec’s ITF USA and SEMICON West’s CEO Keynote Summit to the numerous podcast interviews with industry experts, it all boils down to one key message: The semiconductor industry has the potential to become a $1T industry – and achieve that goal in a way that protects the planet – but it won’t happen unless we work together to create a collaborative semiconductor ecosystem. And it may not happen at all if we don’t solve the PFAS issue.

Jim Morgan. retired CEO and Emeritus Chairman for Applied Materials said it during his acceptance speech as he accepted a lifetime innovation award from imec. He echoed Luc Van den Hove’s point: “We need collaboration as well as competition. Find a way to work together as a global industry despite political differences in geolocations.” He also went on to stress the importance of diversity in building the talent pool. With regard to our impact on the planet, he said, “The climate crisis should be at the top of our agenda when we’re looking at new technology.”

Keyvan Esfarjani, Chief Global Operations officer of Intel, said it during speeches at both imec ITF AND SEMICON West. He stressed the importance of creating a collaborative semiconductor ecosystem to overcome our joint challenges to “pursue sustainable growth”. He said, “We can’t just throw money at this and build factories left and right. We’ve got to do it right. There’s no glory.” He charged the industry with a single challenge: “Grow while reducing our environmental footprint.”

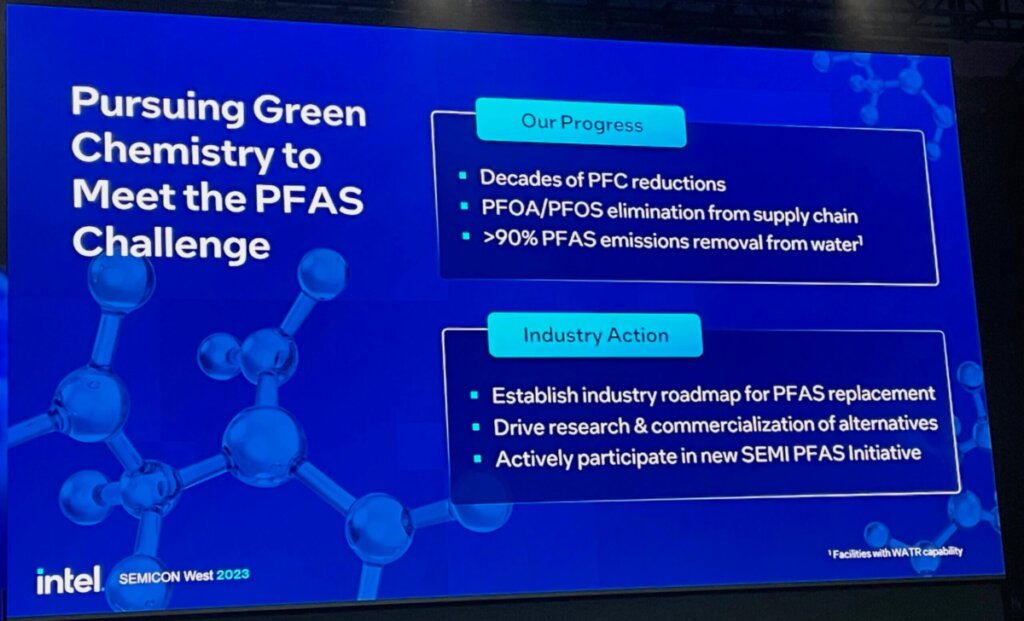

He talked about the work Intel has been doing for over 30 years to address its carbon footprint, highlighting the company’s journey to net positive water, with a $600M investment in a water plant in Arizona. He also tackled the elephant in the room: PFAS chemicals. “This is an immediate issue,” he said. “The call to action is, we’ve got to get off of PFAS and develop green chemistries.”

Tim Archer, LAM Research, said it, as we try to navigate an increasingly complex environment and “manage in a world that’s trying to reverse decades of geographical collaboration with localization focus.” He said Net Zero commitments require a collaborative semiconductor ecosystem. “The opportunity for a trillion-dollar industry is here, but we need to figure out how to solve technology complexity in new ways to support a geographically dispersed industry and do it sustainably.”

Mike Sullivan and Prabu Raja, Applied Materials, both said it during the annual AMAT breakfast when presenting the company’s new collaboration models to accelerate the commercialization of technology innovations and talent development. Raja explained the company’s new EPIC model – EPIC stands for Equipment and Process Innovation and Commercialization Center. He announced a new collaboration with Arizona State University to create a materials-to-fab center at ASU Research Park.

And SEMI’s Ajit Manocha said every chance he got – in all his welcome talks throughout the week, and including in our podcast interview, which drops July 31:

“No single CEO, no single company, no single country, can achieve everything we need to do to meet our 2030 goals of $1T and Net Zero.”

Like Esfarjani, he has put addressing PFAS at the top of the critical list.

The PFAS Dilemma

Per- and poly-fluoroalkyl substances (PFAS) are a group of chemicals used to make fluoropolymer coatings and products that resist heat, oil, stains, grease, and water. They are a concern because, according to the CDC, “they don’t break down in the environment, can move through soil and contaminate drinking water, and build up in fish and wildlife.” Exposure to PFAS has been shown to impact human health. They are used in a plethora of industrial applications, which unfortunately include semiconductor manufacturing.

“With PFAS, we’ve hit a brick wall. At this time, we don’t see alternate chemistries that can replace PFAS and make the chips the way we make them now,” said Manocha, explaining that while the other headwinds we talked about – the talent shortage and the supply chain issues – if they don’t get solved, it will slow us down. “But PFAS will shut us down, because regulators are calling for no more use of PFAS by 2025/26 around the world.”

And according to Manocha, even though the industry has been working for some time to develop replacement chemistries, 2-3 years is not enough time to get there. “And if we shut it down, it won’t only shut down our industry, it will shut down the world,” because our experience with COVID amplified how much the semiconductor industry is central to our daily lives. So, his primary focus is to support members and work with the government to extend the deadline while the industry accelerates R&D and development of replacement chemistries.

Esfarjani pointed out that the climate crisis is not a new problem. He said Intel has been working on it for 30 years, and it’s going to take another 30 years.

But is that 30 more years that we haven’t got? In reality, it doesn’t matter if we don’t reach $1T by 2030, or whether we build 1 Trillion transistors by then, as Esfarjani noted in his imec talk. But it does matter if we don’t achieve Net Zero.

In my podcast interview with SEMI’s Mousumi Bhat and Collin O’Marra, of the National Wildlife Federation that drops July 28, you’ll hear Bhat and O’Marra talk about the urgency we’re facing as the climate crisis worsens.

Quoting O’Marra’s talk in the Climate Equity and Social Impact Pavilion, Bhat said never mind 30 years, “We don’t have 5 years, it has to be within the next year or two.”

“We became good at setting goals that are somebody else’s responsibility – 2030, 2040, 2050, even 2100,” said O’Marra. “But things are a lot worse than we thought… that ‘tomorrow” we’ve been talking about? That’s today.”

Have we progressed? Bhat says yes – what were PowerPoint presentations a year ago have turned into action. Companies with more aggressive goals (2030) are putting pressure on their partner companies that were previously targeting 2040 and 2050. The shift in thinking is beginning to happen.

In his SEMICON West post, Dean Freeman expressed skepticism that the industry is really capable of the kind of collaboration that we need to achieve these critical goals. “Who at the equipment level is going to collaborate with whom? Each company seems to have its own collaboration plan.”

While he may be right, I hope he’s dead wrong. I’m encouraged when I see AMAT collaborate with Besi and EV Group on developing hybrid bonding, which will inspire other suppliers so that companies can both compete and collaborate. If they can do it to develop technology, surely they can do it to address climate change.

Because when it comes to saving the planet, we don’t have a choice but to hit our target date. We need to accelerate progress. It’s not a technology goal that can be pushed out. So whether or not we are capable of creating a collaborative semiconductor ecosystem to achieve Net Zero across the semiconductor industry, we’d better become capable. We need to put individual and company growth goals aside and focus on what’s really important: Saving the planet for ourselves, our children, grandchildren, and generations beyond.