When I interview members for the 3D InCites Podcast at industry events, I often ask them, “What did you come here to learn?” As this is my first time at ISS Europe, I asked myself that question. Here’s what I came up with.

I attended ISS Europe 2024 to learn how it is different from and similar to SEMI ISS in the US. What strategies discussed are specific to the EU? How is the EU Chips Act different than the US Chips Act? How are the regions’ priorities different?

At ISS in January, Entegris’ David Mederios described the difference between the US and the EU succinctly. He said, “The EU is 27 nations acting as a single entity, and the USA is one nation acting as 50 separate entities.” The differences between ISS and ISS Europe are similar.

At ISS, the theme was a question – Ready to Ramp? And the focus was on how to navigate the headwinds that could impede progress to $1T by 2030. There was a lot of focus on technology drivers, advanced packaging, AI, and more.

At ISS Europe, the focus was not so much on reaching $1T, but on how to increase Europe’s overall semiconductor manufacturing market share to 20%, and the importance of collaboration on key issues.

While all strategies discussed were specific to Europe, ISS Europe Chair, Leonard Hobbs, Intel Ireland, noted that Europe is only one egg in the “basket of eggs” that is the global semiconductor industry.

Unlike previous years, there wasn’t much about specific technology advancements, as noted by panel moderator, Michael Alexander, of Roland Berger.

And of course, the main difference between ISS and ISS Europe was the Gala Dinner at the Hofburg Palace. What an evening of fine dining and classical music! The Ritz Carleton is nice, but the experience is beyond comparison.

ISS and ISS Europe speakers alike offered insight into improving supply chain resilience, increasing sustainability efforts, and addressing the talent shortage. Attending both ISS and ISS Europe gave me a bigger picture than attending just one or the other would have. So I recommend attending both. Here are my takeaways from ISS Europe. You can read my post about ISS here.

Europe’s Role in Intel’s IDM 2.0

Keynoter David Bloss, CVP in manufacturing supply chain and operations, discussed Intel’s IDM 2.0 concept and roadmap for the future; and the role Europe plays in helping Intel reach its goals. We heard a lot about the role Intel Foundry wants to play in the region’s growth and its R&D infrastructure.

Bloss noted that Intel believes in its responsibility to achieve its goals sustainably and shared the roadmap to 2050 to meet net-zero upstream Scope 3 GHG emissions.

He explained the global economic implications of achieving $1 Trillion by 2030. “Every semiconductor sales dollar generates $13 of GDP,” he said.

Bloss said creating a balanced supply chain focused on capacity and resiliency is important. He identified chemical manufacturing as an area that needs particular attention.

“While manufacturing capacity is going up in the Western world, chemical manufacturing is going down,” he noted. “That’s a problem if we’re going to achieve 50-50 goals.” By that, he meant the goals of the U.S. and Europe producing 50% of the world’s semiconductor capacity and Asia producing the other 50%.

He called for regionalizing the chemical supply chain with the following calls to action:

- Accelerate investment in research including PFAS alternatives

- Build the chemical ecosystem to support growth

- Collaborate to enable a balanced and resilient EU supply chain

Playing Up Europe’s Strengths

Looking into his crystal ball, Handel Jones, International Business Systems, talked about the benefits of generative AI in semiconductor manufacturing and the value it will add to semiconductor chips. He urged companies to implement Generative AI in their manufacturing practices. He also encouraged Europe to focus on its strengths in automotive, MEMS, and sensors, and to build a software ecosystem.

From Yole Group’s Jean-Christophe Eloy, we learned that while the EU Chips Act will attract more investment in leading-edge manufacturing technologies, it won’t increase the region’s market share. Where Europe shines is in automotive and specialty markets. Additionally, wafer fab equipment is a strong market for Europe. He urged attendees to leverage our strengths in equipment, equipment subsystems, and components to hold its spot as world leaders.

Redesigning the Semiconductor Supply Chain

From Infineon’s Silke Sorger, VP of Procurement, we learned about the disruptive events that have strained the global semiconductor supply chain, namely: Emission policies and rising energy costs; logistics constraints; ongoing regional COVID lockdowns; the impact of the Russian War on Ukraine; rising geopolitical tensions; high inflation and wage increases; and a supply chain not in line with fab expansion.

There’s no doubt that the semiconductor supply chain is due for an overhaul. Sandrine Bronner, Edwards, hit the issue squarely by quoting Albert Einstein: “The definition of insanity is doing the same thing over and over and expecting different results.” Her overall philosophy is straightforward: “Plan for the worst and hope for the best.”

Bronner’s approach to supply chain strategy involves shifting how we think of and respond to the challenges. She talked about the acronym, VUCA that describes the traditional response to supply chain disruptions: Volatility, Uncertainty, Complexity, and Ambiguity. She replaced these with positive words: Vision, Understanding, Clarity, and Agility. Same acronym; new strategic approach.

In this way, companies can shift from being reactive to using agile and lean approaches to be responsive and proactively collaborate.

Dionys Van de Ven, Comet Yxlon taught us a new word: Ednovation. He defined it as something triggered into the semiconductor market because we were behind such as investments in education to upskill and reskill the workforce. He said we can’t look at the traditional supply chain for solutions because it won’t bring us further into the future. We need Ednovation, agility, and sustainability to adapt better to changes in the market.

DB Schenker’s Stefan Kester suggested that companies rethink logistics as part of their supply chain strategy. instead of dealing with logistics internally and juggling deals with several suppliers, they can outsource it to a logistics company.

Battling Sustainability with Digital Twins and AI

We learned that the highest average temperature was recorded in September 2023, and were reminded that IC chip manufacturing accounts for the largest share of the climate impact. 40 fabs are being built in the EU today. That number is projected to increase to 90 fabs by 2040. If we continue to grow in this direction, noted Fabien Chene, head of sustainability at Schneider Electric, so will the emissions we produce.

However, the EU pledged to become the first climate-neutral continent by 2040 and wants to reduce its emissions by half by 2030.

Schneider Electric is helping partner companies optimize fabs with AI and machine learning (ML). They have been able to detect hidden anomalies, identify energy savings opportunities, and optimize energy usage, resulting in $30M estimated cost savings.

Imec developed a life-cycle inventory model designed to help the industry reach sustainability targets by determining energy and water usage. By reducing process steps, manufacturers will reduce both energy consumption and water usage.

Siemens is using digital twins models to achieve 30% energy savings. Digital twins give you transparency before production by allowing you to evaluate and test options.

Athinia’s data model helps users understand and prioritize the most important levers for sustainable semiconductor manufacturing including:

- Reduce process gas emissions

- Develop new technologies to mitigate energy consumption

- Share data along the value chain

- Provide materials and process intelligence for sustainable innovation

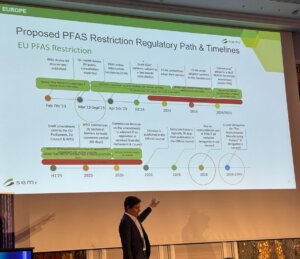

SEMI’s PFAS working group (WG) now has 300 participating members from industry, academia, and government entities. According to SEMI’s James Amano, the WG developed two submittals illustrating the depth and complexity of the industry’s uses of PFAS and emphasizing the need for a comprehensive 12-year derogation for the entire semiconductor value and supply chain. His plea to the room: Get Engaged.

Leonard Hobbs echoed that in his closing comments, “PFAS is scary. By 2040 we need a solution.”

Winning the War for Talent

At a conference where “collaboration” was a key message, I found consistent references to the “War for Talent” to be an interesting choice of words.

During the panel discussion, Moderator Cassandra Melvin, SEMI Europe, noted that this is the fourth ISS Europe in a row to host a panel discussion on how to address the talent shortage, yet nothing has changed. While this is partly due to increased demand for workers from capacity expansion, Isabella Drolz of Comet Yxlon pointed to the semiconductor industry’s image problem.

“The whole world is looking for young talent,” she said. “We are trying to attract people outside our industry. We need to lower the barrier to entry. Austria does a good job working together with companies to promote their regions.” She stressed the importance of engaging with schools and universities and noted that it’s not a sprint and will take time.

Catherine Le Lans, Synopsys countered with the urgency of solving this issue now. “The age of people in microelectronics is getting older,” she said. “Young people aren’t interested in what we were interested in. We have to understand them and use their language.”

Here’s the reality – the semiconductor industry’s talent shortage is a global issue, and there are only so many STEM graduates to go around. The industry is not only competing with other STEM fields for this talent but also with each other. Not only do we need to convince young people to pursue a STEM career, we need to convince them that when it’s time to find a job, your company, city, region, and country will allow them to live their best lives.

Lessons Learned from Eastern Europe

When it comes to sustainability regulations, STEM talent, and a high percentage of women in the workforce, it seems Europe needs to look no further than the former Eastern Bloc regions—Saxony in Germany and Pomerania — in Poland for lessons learned.

From Andreas Lippert of Silicon Saxony, we learned there is no other region in Europe where so many parts of the value chain are densely packed in one small region. He called it a safe option in which to build a resilient ecosystem. Already tough regulations on sustainability make it a good launchpad for Net Zero emissions rules for the entire ecosystem.

Its high-ranked education system focused on STEM and a childcare system initially borne of necessity due to the workforce scarcity of the former GDR, makes it possible for both partners to work.

Lastly, utility suppliers know how to work with the needs of the semiconductor industry.

In fact, the city of Dresden invested more than 300M in its water supply system to prepare it for future infrastructure build-out.

From Mikolaj Trunin, we learned of Pomerania’s plans to become a semiconductor hub in Poland. Intel is targeting the region for assembly, test, packaging, and advanced packaging. Gdansk already boasts Intel’s biggest R&D center in Europe, with 3500 employees, and plans growth to 6000.

What makes the region so strong? For the last 20 years, STEM education has been a focus, and 43% of STEM graduates are women. “Polish women are powerful and ambitious,” noted Agnieszka Szweda.

Additionally, Pomerania is investing heavily in sustainable energy, developing offshore wind farms, and generating 1.6 GW of nuclear power.

Final Thoughts on ISS Europe

Despite the call for collaboration on all the challenges facing the industry – there is still competition for market share (20%) and workforce. We must be careful of becoming too regionalized. I was happy to see that both Leonard Hobbs, event chair, and SEMI CEO Ajit Manocha share the same sentiment.

Hobbs noted that collaboration needs to be structured and orchestrated to work. Luckily, Europe is good at this. However, Europe can be too focused on being Europe, and we need to remember that this is a global Industry.

SEMI CEO, Ajit Manocha encouraged European executives to “bring up the jewels of your countries and let SEMI connect you with the rest of the world.” He stressed that it’s not only about what’s good for Europe it’s about what is good for humanity and what role Europe plays in making that happen.

I caution the U.S. of the same thing. We are very caught up right now in reshoring everything out of concern for “National Security,” But as one attendee from Huawei explained to me, restrictions on legacy node MOSFETs used in automotive applications can hardly be considered a danger to national security. At the end of the day, the semiconductor industry spans beyond geographic and geopolitical borders. When we put all the eggs in the semiconductor industry basket, everyone wins.

We’ll bring more of ISS Europe to you this week and next, on the 3D InCites podcast. Additionally, Steffen Kröhnert, ESPAT Consulting, is preparing a full report of the event, which he is making available to 3D InCites members at no charge.

Next year, SEMI Europe will be held in Sopot, Poland on March 13-14, 2025. Mark your calendars!