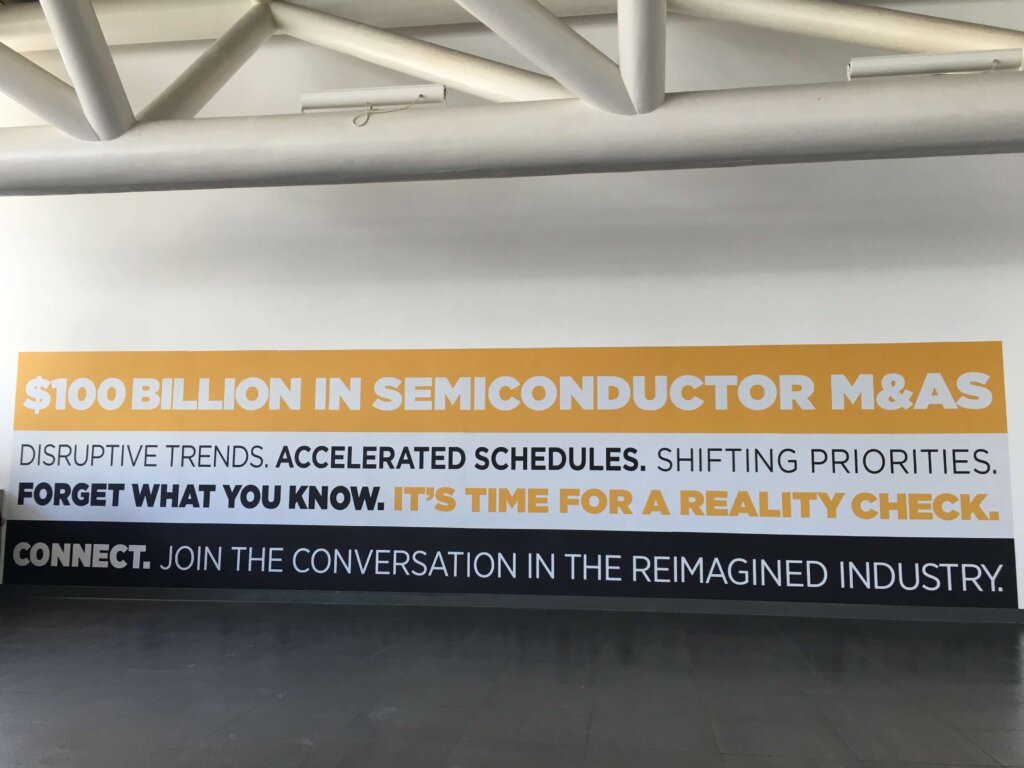

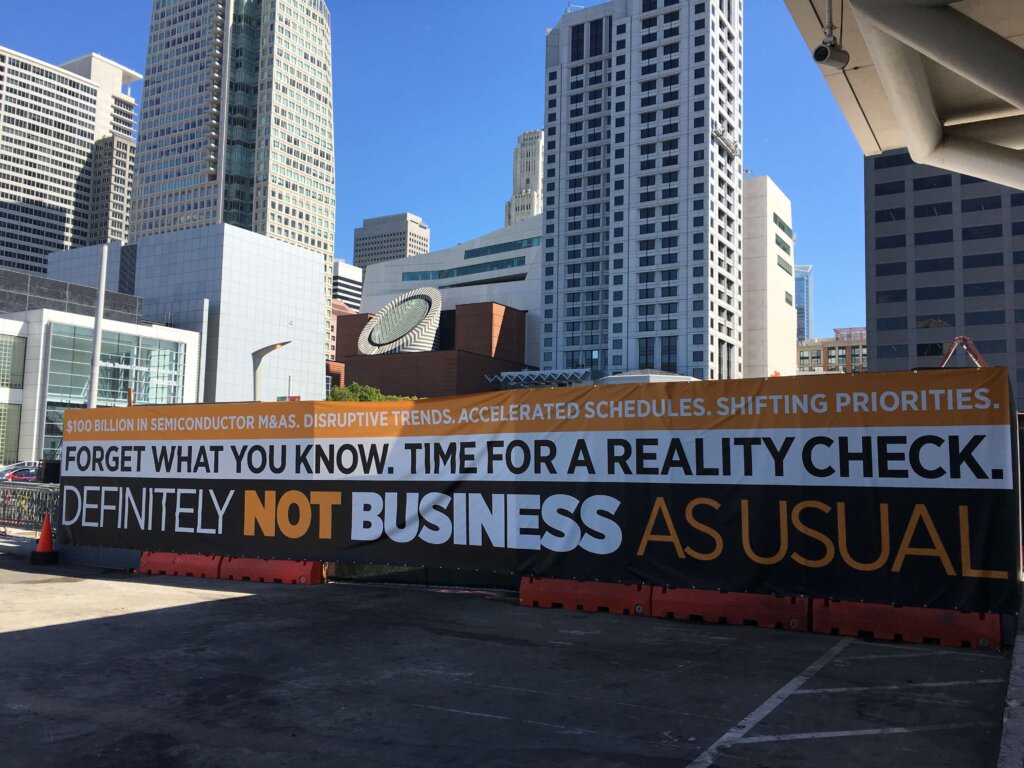

If you attended SEMICON West 2016 last week, you probably noticed that the event is undergoing a metamorphosis. It was hard to miss. The signs were everywhere. Literally:

It’s not surprising, since everything about the semiconductor manufacturing industry has been evolving over the past few years, and everyone, including SEMI, is feeling the impact. As Karen Savala, President, SEMI Americas, explained during the opening keynote, massive industry consolidation and realignment to the tune of $100B in mergers and acquisitions; the increased demand due to the Internet of Things (IoT) and Smart Manufacturing (actually, smart EVERYTHING); and new device types, processes, and material changes has made all of us question the way we do business. Now, it’s all about a tighter, integrated supply chain driven by the system integrators; shorter cycle times; tighter inventories, and most importantly, collaborating with industry partners.

SEMI sat up and took notice, and with SEMICON West 2016, has kicked off a four-year initiative, dubbed SEMI2020, to transform, re-tool, and expand not just SEMICON West, but all the SEMICON events to better serve the needs of its members, and also to recruit new members and partners to reflect the need for making connections across the entire supply chain. As Savala noted, the microelectronics industry has become ah interdependent supply chain, where we can achieve together what we can’t do alone. SEMI’s focus will be to grow partnerships and refresh connections to the industry. This video tells the story well:

“Collaboration” was just one of the buzzwords echoing around the Moscone Center, from John Kern’s keynote presentation to the Connect Executive Summit panel, to the expanded forums. Others included “connections” “ecosystem” “heterogeneous integration,” “Internet of Things” and the “renaissance of 200mm fabs” (yes, you read that right.)

Kern, who is Sr. VP of operations at Cisco Systems, said that there’s never been a better time to connect. He also noted that connecting the unconnected would be a huge challenge over the next five years. Cisco is relying on the semiconductor industry to achieve its goals of digitizing its supply chain. “If you’re not investing in digitization today, its difficult for you to remain relevant in the future,” he noted. He cautioned against commoditization, but rather to invest in concepts that enable a connected world to stay relevant over time.

“We fundamentally do not believe that commoditization is a good path for the semiconductor industry,” said Kern. Rather he said Cisco is willing to pay for the added value realized by innovation, and would continue to invest in the industry.

The discussion during the Connect Executive Summit centered on the opportunities made available by the IoT, and the collaboration required in achieving them.

Bridget Karlin, Intel noted that the cost of sensors and connectivity has come down dramatically, and the cost of computing has also come down. That combined with the expected 50 billion connected devices containing 212 billion sensors generating 44ZB of data that needs to be measured in real time and accessed from anywhere is creating a USD $411 trillion economic opportunities. “You can take advantage of IoT growth opportunities by rethinking your business and finding new ways to drive value,” she said

The importance of securing the IoT has become paramount, and requires both hardware and software solutions to create a robust, secure processor, noted Michael Campbell, Qualcomm. However, he added that hardware will be the smallest portion of the revenue stream. The value-add will be in the repackaged data.

The IoT is also responsible for the renaissance 200mm fabs is experiencing. Campbell said the IoT is allowing us to use obsolete technology for better purpose. There is a need for lower-power chips, and this is what is filling the 200mm fabs. He talked about the importance of a collaboration model that extends from design to materials, all the way to the equipment supplier. In fact, imec’s new R&D center in Osceola, FL utilizes a legacy 200mm fab.

Bernard Loy of Entegris offered the equipment supplier perspective, noting that all 200mm customers are running at full capacity, and they are interested in discussing new solutions to reduce defects and increase yields and improve cost-of-ownership (CoO).

Additionally, Karlin noted that as both an IoT provider and user, Intel is starting to live up to the IoT hype. “Adoption is happening. We spend $10B a year on capital equipment. There is $685M capital equipment in transit on any given day. We rely on our supply chain to be efficient,” she said. “No single company has everything you need for end-to-end IoT. You need to think about a broader set of partners, understand your core competencies, and identify the gaps and who are the partners that can address those gaps.”

Tim Archer, Lam Research, concurred. He brought the conversation back to the importance of collaboration, noting its importance in productivity, how MEMS and sensors are made, how the advanced packaging is done, all the while enabling 7nm node technology. An investment in technology is critical to success, he noted.

And that brings us full circle to the changes we will see at SEMICON West and other SEMICONs around the globe. Because as Loy so aptly put it: “What makes this industry exciting, is the many bright people who will find a way to keep driving technology to next level of performance; that’s exciting for all of us. SEMI can play a great role. We can change the way we are willing to collaborate. Other industries have done it, and I want to believe SEMI has a role to play.” Amen to that. ~ FvT