The Semiconductor industry has been ramping up its focus on sustainability for the past three to four years. Strong sustainability efforts have been in place for ST Microelectronics and Intel since 2011 and have trickled down to their suppliers through a sustainability focus on the supply chain. When Apple and Google stated in 2020 that they would become carbon neutral across their supply chains, sustainability for the semiconductor industry kicked into high gear.

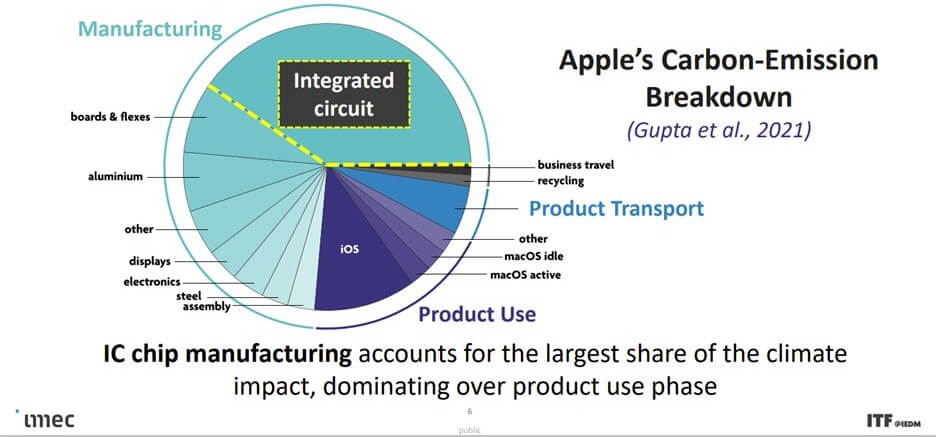

A paper written by Harvard, Facebook, and ASU stated that the semiconductor industry had a dirty little secret, and helped to accelerate semiconductor industry climate action. They created a breakdown of Apple’s carbon emissions breakdown. Soon after the report was published SEMI jumped on board and formed the Semiconductor Climate Consortium, which participated in COP28 last month.

However, you know for sure that the industry is all in when the IEDM, one of the premier industry technology conferences dedicates a session to sustainability. At the 2023 IEDM conference in San Francisco, session 28 was dedicated to sustainability. This was scheduled as a focus session, which means that the committee thought there was sufficient interest in the subject to invite presenters to give their views on sustainability in the chip industry. It will be interesting to see if the IEDM thinks there is enough interest in sustainability to continue offering a session at the conference. There were six papers on the topic, and all of them had a somewhat different focus on the sustainability topic.

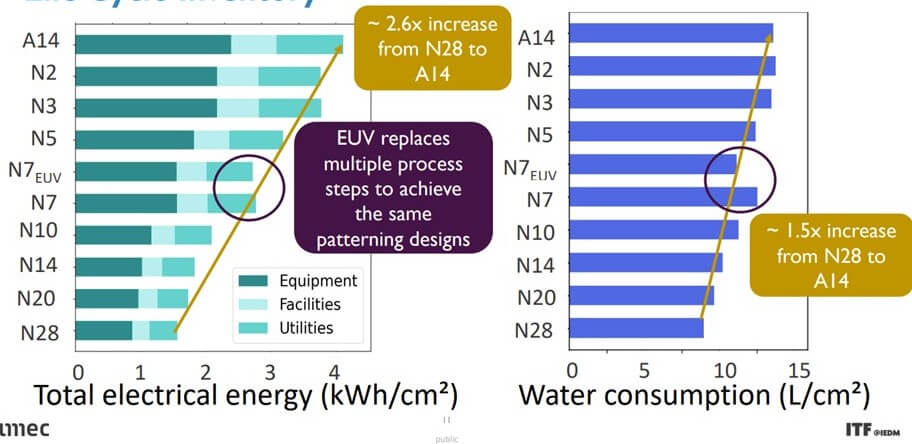

Imec led off the session with an update on its carbon footprint model, which looks at the CO2 footprint life cycle of semiconductor chips from 28nm to 14A. Imec has been modeling industry CO2 footprints across the life cycle of the process since 2019. So, the discussion was focused on the results of continuing to fine-tune the model. The model shows that using the current process technologies the CO2 footprint and the water footprint continue to increase, as can be seen in Figure 1. There is a little relief when EUV comes on board, but it is short-lived.

Imec’s conclusions at this moment are that 1) abatement needs to be employed to help reduce scope 1 greenhouse gas (GHG) emissions, 2) using greener electricity can reduce global warming potential (GWP) by 3x at advanced nodes, and 3) materials such as silicon, wet chemicals and casing head process gases (CHG) need to be reduced to improve the industries carbon footprint. Imec has developed a net-zero model that can be used for fab-level GHG modeling that is available for partners.

Applied Materials (AMAT) discussed the internal activities it has implemented to reach its 3×30 goals to reduce energy, environmental impact from chemicals, and cleanroom footprint by 30% by 2030. In its evaluations, AMAT needed to look at not only its equipment but also its supplier’s equipment that is needed to operate AMAT’s equipment. This also includes looking at how much energy is needed to purify water that is used to operate the equipment, as well as HVAC, exhaust, and cooling water.

AMAT has created internal and external models that look at its product solutions’ energy consumption and chemical impact before they are implemented. Engineers can use a model to look at different process parameters and the potential GHG impact they might have before running wafers on the hardware. Applied uses the IMEC net-zero model along with its internal models to look at how to improve equipment footprint, and new processes to reduce GHG emissions.

Scotten Jones presented the TechInsights Semiconductor Manufacturing Carbon Model (TCM) The TCM is based on the former IC Knowledge Strategic Cost Model (SCM). The model covers 167,300 mm fabs and 220 process flows. The model enables you to look at the energy consumption and the GHG emissions. The model was validated to GHG energy emissions, and GHG process chemical emissions reported by the fabs, and had an extremely good match. Jones pointed out that improving abatement is critical for reducing process GHG emissions. One of the best soundbites of the entire conference was that renewable energy credits (REC) do not equal decarbonization. We’ve highlighted this before in other blogs. The industry needs to create more power purchase agreements or build its renewable supply to ensure the industry is on the path to decarbonization rather than rely on REC.

Theo Thijssen of ASML discussed ASML’s efforts in the continuous improvement of the EUV lithography system, such as H2 recycling, improvement of CO2 laser performance, use of cooling water more efficiently, and the development of a sleep mode for the tool. The source efficiency was improved by 280% from the 3400 to the 3800 system.

Samsung presented work being done in the fabs to improve air quality by removing contaminants from the fab airstream. Samsung developed a ceramic filter that is effective at removing volatile organic compounds (VOC). The filter is also reusable and can be recharged just by rinsing in water. Samsung proposed that the filter could potentially be used in other settings to help with VOC removal. Samsung also presented on using photocatalysts to assist with VOC removal. The company developed a biocatalyst to help convert NOX to N2. Most interesting was its carbon capture process, in which a membrane is used to capture the CO2. Then by using methane, they form H2 and CO, syngas, which can then be used to power the fab. I’ll be interested in following these applications to see if they become commercially viable.

ST Microelectronics, which at the moment is the first semiconductor company scheduled to get to net zero, which will be in 2027, gave an overview of its sustainability practices. ST explained how responsible products are classified into four categories reflecting their intrinsic eco-design attributes or their ability to enable sustainable applications. The first category is low-carbon products, which exhibit a low production footprint. ii. The second category is power-efficient products, which consume less electricity while operating. The third category is planet-friendly products that enable greener solutions, and finally, human welfare products that improve end-user quality of life. The discussion included its responsible mineral initiative and the removal of PFOA-free (perfluorooctanoic acid) from their process flow.

From a sustainability viewpoint, the industry is making progress. While some companies such as ST Micro, have been working on sustainability for a considerable time, for others it is a more recent focus. Let’s hope the industry can keep up the momentum, and get to net zero sooner than later.