Sustainability and collaboration are two keywords that are being used in the semiconductor industry. On the chip and equipment development side, collaboration means perhaps more open and active co-opetition. But on the sustainability side of the semiconductor world, active collaboration started at a grassroots level.

As the semiconductor and semiconductor equipment companies came to grips with how to reduce their carbon footprint, they struggled to find startups working in the sustainability space with technologies that were applicable to semiconductors. The venture groups working to help find sustainability solutions for their parent companies started working together with SEMI to create the Startups for Sustainable Semiconductors (S3 Forum).

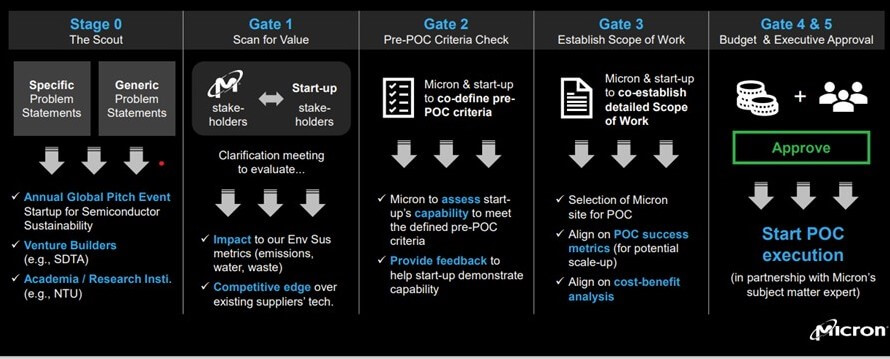

In the S3 program, start-ups with good sustainability ideas can apply to participate. It involves a fairly significant selection process from the initial application to semifinalists, where the vetting gets serious, but along the way, the startups are exposed to companies that might have an interest in their technology and get pointers on how to work with the semiconductor industry and get to a point where they can show proof of concept.

According to the venture panel at the 2023 S3 Forum, some of the semifinalists, while they did not make the cut to be a finalist, are still being considered for their technologies, but the company or product needs to mature a bit before they are ready for proof-of-concept so they are being helped along.

From a sustainability perspective, building semiconductors takes energy, chemistry, (gasses and chemicals), and water; lots and lots of water. The energy to manufacture semiconductors falls into primarily Scope 2 emissions and is being resolved mostly by using renewables. The chemistry falls into scope 1 and scope 3, and there is a need to either decompose or recycle the chemicals, such as SF6, NF3, and fluorocarbons used in etch deposition and lithography. From the water standpoint, there is the purification of incoming water which takes energy, then there is the recycling, and the final purification, eliminating the fluorides, chlorides, and ammonia used in the cleaning of wafers and the chemicals used in the CMP process.

The 2023 S3 Forum focused on the critical areas of emissions, energy, and circularity (waste and water). Eight finalists pitched their products to the audience. Micron and TEL, kick off the session to describe a bit more in-depth how the process works. Closing out the day’s program, the VC panel also went more into depth about the program and thought process (Figure 1).

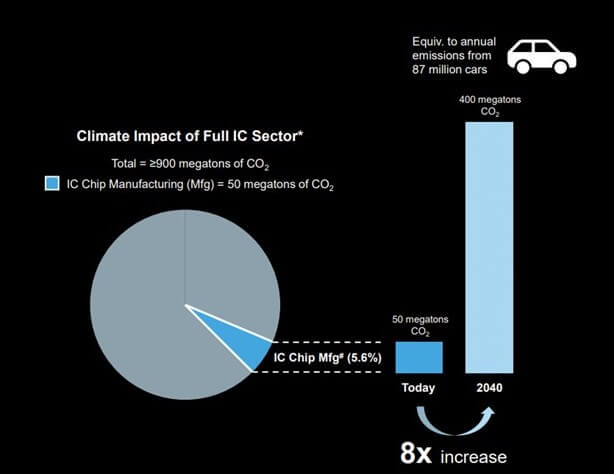

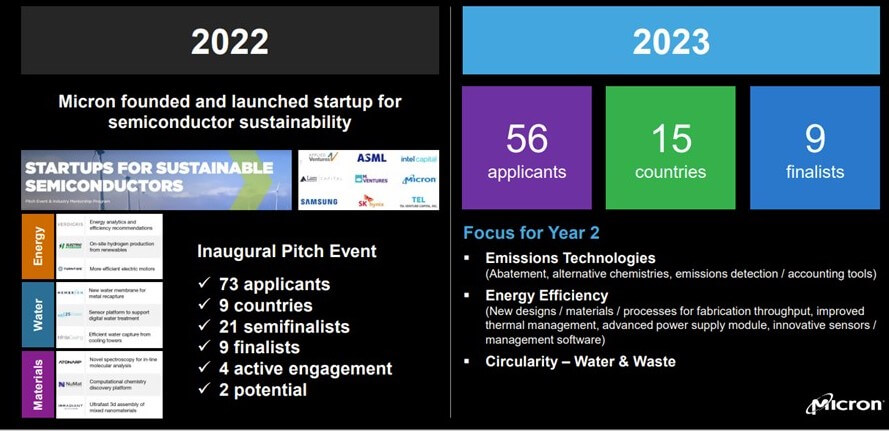

Beth Elroy of Micron quickly summarized the challenge facing the industry by informing us that if the semiconductor industry does nothing, GHG emissions will increase 8 times by 2040. Elroy also shared Micron’s sustainability accomplishments. Micron has made up a lot of ground in a short time on its sustainability focus. Elroy quickly shifted gears and got into why we were all here: The Startup Summit. Figure 2 goes into some of the key numbers for the startup program for 2023, 56 applicants from 15 countries were whittled down into the 9 finalists.

Elroy also shared a methodology on how to get from idea to “the clean, mean proof of concept machine.” This graphic is a key point for getting sustainability projects from idea to production. As was shared by the VCs later in the day, semiconductor companies are notorious for taking a long time on introducing new things to the manufacturing process. Since the goal of most major semiconductor companies is net zero between 2030 and 2040, a quicker time-to-market process is critical for the industry to meet its sustainability goals.

Kay Enjoji of TEL Ventures shared on TEL’s venture program. Enjoji pointed out that there are 37 startups in Japan with a semiconductor or ESG focus. TEL has multiple projects that they have been working on such as; Looking at how to abate or replace PFAS chemicals using a chiller project as an example. Moving to SiC to improve power loss, and a water and IPA separation technology to reuse IPA, and I imagine also recycling the water.

2023 S3 Forum Finalists

Out of the 56 companies that started this process, the nine 2023 finalists are:

Purity Resources, Chemical Recycling

Purity Resources is looking at how to recycle chemicals on site in the fab, potentially to the purity that the fab can then re-use, thus saving costs as well as cleaning the waste stream. IPA is the first test case, and other solvents will be worked on at a later time.

Aqua Membranes Printed Spacer Technology for Reverse Osmosis

Aqua Membranes has developed a printing process for RO filtration of water. The design is expected to reduce water waste in the filtration process, as well as improve production while reducing energy.

Corintis, Using AI and Nature to Cool Chips

Corintis is using bio-inspired microfluidic cooling found in nature to cool semiconductor chips. Using AI, they can look at the power map on a chip or package, and then AI designs the optimum cooling pattern. This will hopefully help to reduce the power and water used to cool data centers.

Multiscale, An AI-powered Accelerated Materials Innovation for Sustainability

Multiscale is developing an AI platform to work on design optimization, chip floor planning, reliability analysis and, failure prediction, and fault detection and diagnosis.

CFEX, A Scope 2 Enterprise Decarbonization Platform

CFEX has developed a cloud-based software program to assist companies in tracking their Scope 2 emissions. CGEX has broken its service into 3 products, Meter to Carbon, which is scope 2 carbon accounting. Meter to Cost which looks at carbon costs and cost analytics, then Meter to Cash which is a platform for CFE transactions.

GRAPHEC, PFAS-eliminating Electrochemical System

Graphec has developed an electrochemical process that can remove PFAS from the waste stream. Using a direct electron transfer GRAPHEC has achieved 77% defluorination in waste streams.

ElectraMet, Selective Copper Removal, and Recovery

ElextraMet has developed an electrochemical process to remove copper from the waste stream, it can also be used for other metals. It also creates the possibility that the copper CMP slurries could be recycled and potentially reused. Reducing waste, and lowering the CO2 footprint.

Innoflex, A Method to Clean and Mineralize CO2

Innoflex is looking at using a photocatalyst to remove GHG from the waste stream and potentially mineralize CO2.

L2X Labs, A new EUV Source

L2X Labs is developing a new EUV source, that provides a second source for EUV, but also looks at reducing the energy consumed in the process.

It will be interesting to follow these companies through the rest of the process and see their successes in helping the semiconductor industry achieve its sustainability goals. Some of the companies have completed proof of concept and are ready to implement in a production environment, others have completed the lab tests and are scaling up to get ready for the large-scale POC. If you have an interest in contacting or working with these companies’ contact SEMI. If you have a sustainability idea, also touch base with SEMI, as the process for 2024 is beginning.

Editor’s Note: The 3D InCites podcast featured interviews with finalists from the 2022 S3 Forum. Check them out here: