There’s no doubt left in the minds of semiconductor device manufacturers that the processes required to build interposer-based and 3D IC devices are matured and ready for production. However, the jury is still out in the design community because designing 3D ICs still poses a challenge. Si2 has set out to change that and bring confidence to the minds of chip and system-level designers. Steve Schulz, CEO of Si2 talked to 3D InCites about the organization’s efforts past and present, and offered insight into what has held up the design community from going full steam ahead with 3D IC designs.

There’s no doubt left in the minds of semiconductor device manufacturers that the processes required to build interposer-based and 3D IC devices are matured and ready for production. However, the jury is still out in the design community because designing 3D ICs still poses a challenge. Si2 has set out to change that and bring confidence to the minds of chip and system-level designers. Steve Schulz, CEO of Si2 talked to 3D InCites about the organization’s efforts past and present, and offered insight into what has held up the design community from going full steam ahead with 3D IC designs.

Si2’s Back Story

As EDA tools gained commercial success in the late 1980’s, a need emerged for interoperability among the tools. “Si2 was initially chartered in 1988 to address design flow interoperability of data exchange between EDA tools for front-end design,” explained Schulz, adding that in the late 90’s it was re-chartered to serve broader functions, such as hosting industry councils. Si2’s core focus is to establish design standards around both established and emerging technology areas and enable market adoption. Si2’s staff comprises full and part time employees and contractors. The non-profit organization relies on the efforts of its 100+ corporate members, who lead Si2’s seven major projects, and contribute both time and technology to create standards and establish best practices. Si2’s staff helps facilitate their success by providing program management, developing needed software to support the standards, create documentation, and manage and maintain the Si2 website and its servers.

Schulz shared one of Si2’s early success stories, the OpenAccess Coalition, to illustrate the organization’s effectiveness. This community effort was launched to provide true interoperability, not just data exchange, among IC design tools through an open standard data API and reference database supporting that API for IC design.

Creating OpenAccess API posed an enormous risk because it involved 1.5M lines of source code that would be used by all EDA vendors; something that had never been tried before, explained Schulz. “It required a lot of education, but it worked, and worked well. But it took a while,” he noted. “There were questions about the cost, about keeping it current, and about proprietary and competitive issues. It took about 5 years or so before we were confident it would succeed.” Si2 continues to support and update the ecosystem around OpenAccess.

Efforts Turn to 3D ICs

With any new technology paradigm shift, there needs to be an education to help design engineers find out how to get started. “Engineers are busy. Before they are willing to make a commitment – before a program manager is willing to take a leap of faith – he or she needs to be confident that all the pieces are there,” explained Schulz. To design in 3D, an efficient, streamlined 3D design flow is required, and not having all the pieces required has held it back, he said.

In 2009, some Si2 member companies expressed concern that without open standards on the design side, 3D would never take off. “We needed to form a project around interoperability challenges for 3D IC,” said Schulz. The Si2 board of directors approved the project and the intent was to ramp immediately, but building membership proved the market was not ready, so they held off.

In 2011, 18 companies were ready to launch the Open3D project. Understanding the uncertainty around commercialization of 3D ICs, extra efforts were made to keep costs down. As such, the project was structured as a technical advisory board, and Open 3D TAB was born.

The Open 3D TAB hit another snag when launching the first standard for designing power and ground networks in a 3D stack. Schulz explained the standard focuses on how to exchange data regarding location of power and ground networks on one die vs. another die that’s being designed, how the dies relate to the package, and how the distribution network work with regard to the other die, package and board. During the development process, a set of external patents was discovered, and members requested Si2 input to provide safe legal guidance and resolve a potential stalemate, after which the members unanimously approved the standard for release. While the situation created enough ambiguity and uncertainty to elicit a pause in progress of about one year, three design standards were successfully developed, with two released and a third in final approval. Before proceeding with development of additional planned standards, Open3D TAB members are collecting updated industry input on current priorities and needs through an online survey (see below).

While some EDA vendors initially balked at the idea of OpenAccess, Schulz says for designing in 3D, it is essential for the market to have confidence and depend upon the design standards. When designing in 3D, it can’t be assumed that die at different companies are designed with the same tools. Open design standards ensure that data can be exchanged and communication is possible between the whole ecosystem, including foundries and OSATS.

3D IC Design Challenges

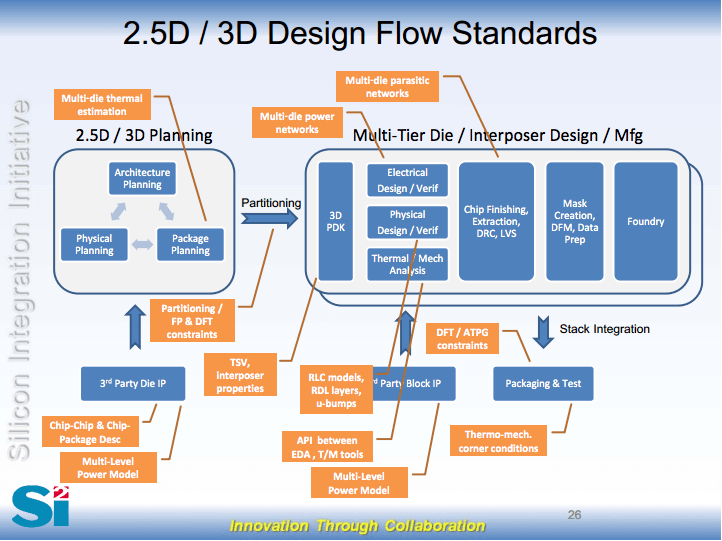

As previously mentioned, while processes for 3D stacks are well understood, a lack of design standards makes designing 3D architectures difficult, explained Schulz. He referenced a slide about (interposer) and 3D design flow standards from his recent presentation at the 3D ASIP conference (Figure 1).

The orange boxes point to the high-level design flow where standards are needed based on input from member companies. He said only some of them are needed now; others will become important later. “Can we design in 3D now without design standards? It’s hard to do, but it can be done within limits,” he said. “Using the power distribution network standard for chip to package interface, it helps a lot. You can design without the standards for partitioning and path finding, but you have to make assumptions. In more sophisticated designs, making assumptions won’t be good enough to get the needed performance.” While all of the suggested standards are good ideas, Schulz says only a few are deemed essential to get the right things done for a 3D design.

What does 3D IC Success Look Like?

Four or five years ago, the understood premise was that 3D would be required to get all the functionality and performance we needed into a smartphone. But as other ways have been found to get the job done, that premise has proved false. Schulz says now we have to look at whether 3D will be helpful in smartphones going forward. “It is the head of the arrow to drive cost and get the scale up,” he said.

“Products in the Internet of Things (IOT) space might start to do that. 3D memory is a special case. More variations of use will create demand for more data exchange.” Schulz says he thinks we are 2-3 years out for mainstream, commercial success. 3D Memory stacks will propagate confidence for use in wider applications. “At least getting a couple of products into high volume manufacturing and proving its profitable can start happening this year. ” This will encourage companies who want to take 3D memories and integration them with other things.

“I think that there needs to be a sense of confidence out there, that 3D design is not a black art, but another technology option that has a known methodology, a known flow, and a known cost impact,” said Schulz. “Success has been held back because companies are still have fears and uncertainty that is holding them back from taking the plunge.”

He compared the commercialization of 3D ICs with that of FPGAs, another technology predicted to have limited value because of high manufacturing costs. “Now 25 years later, FPGAs are doing just fine,” said Schulz. “They haven’t taken over ASICS, but there are definitely a wide range of market applications that can bear the extra cost, reduced clock rates and high power consumption.” The point is, like with FPGAs, for 3D IC Schulz says we need to find where the market demand is where 3D IC is the best alternative.

The SI2 Survey

Given the state of 3D IC commercialization in 2015, Schulz said the Open3D TAB decided to revisit the priorities of the 3D community before proceeding with the next set of standards. They’ve put together a survey to discern what is most important as the next task of 3D design with regards to interoperability and standards. The survey can be found here. Please do your part and take a few moments to complete it. ~ F.v.T.