On January 17, Finetech participated in the Massachusetts Institute of Technology’s (MIT) Integrated Photonics bootcamp, a week-long, hands-on learning experience at the MIT nano facility. The training allows participants to explore and learn to solve problems using lab equipment, preparing them for the challenges they will face in the workforce.

The session covered precision bonding fundamentals: optics, die and substrate temperature, alignment tolerances, thermal mismatch, inert atmosphere, and force. A review of bonding technologies included thermo-compression and thermo-sonic bonding, and UV adhesive cure.

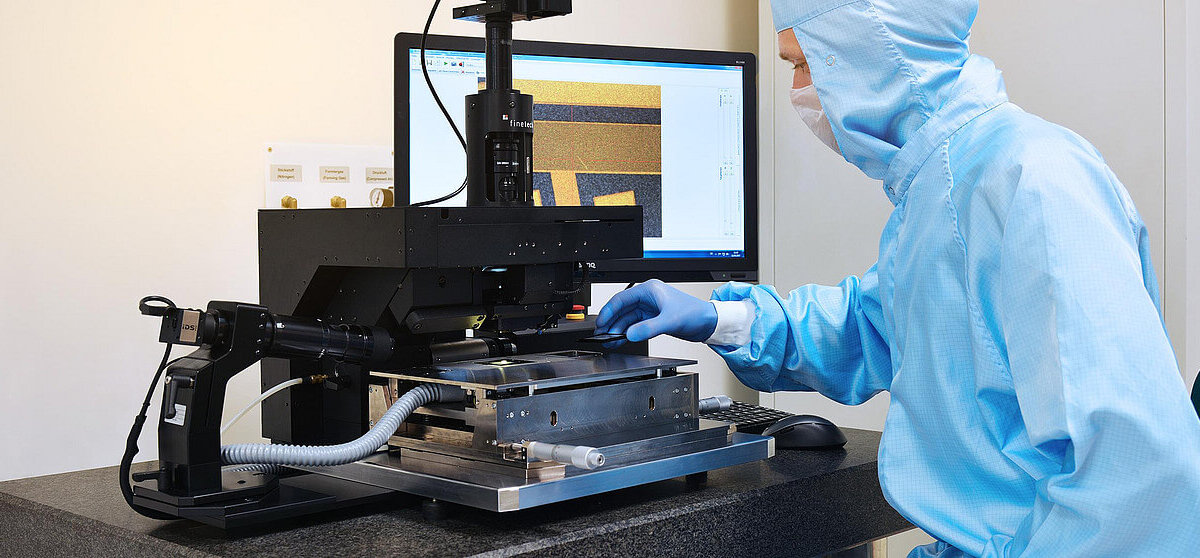

Finetech provided a demonstration of flip-chip bonding using the FINEPLACER® lambda bonder. Participants learned about one of the most critical bonds in a complex surface mount photonic device: the assembly of QFN low-profile quad transceiver modules using thermo-compression bonding of a VCSEL onto a sapphire substrate. Each student had an opportunity to “drive” the equipment to get a feel for the sub-micron placement accuracy of the system.

Anuradha (Anu) Agarwal, Principal Research Scientist at the MIT Materials Research Laboratory and Leader of the LEAP (Lab for Education and Application Prototypes) Program, was a bootcamp instructor and instrumental in organizing the program. Following the event, Anu stated, “The Finetech team highlighted the ability of the FINEPLACER® lambda tool in achieving the desired accuracy for mounting III-V based laser dies onto an optoelectronic silicon chip. This is something desirable as we move forward with integrated photonics packaging. MIT values Finetech’s partnership in education, as we train (or re-skill) people for next-generation jobs in manufacturing. We look forward to more such educational opportunities with them in the future.”

Indium Corporation, a materials manufacturer and supplier, partnered with Finetech to talk about the chemistries and physical properties of bonding materials, and the importance of using that information to select the right materials for their application. “We were pleased to have the opportunity to partner with Finetech and MIT for this event. It provided us with the opportunity to educate students and industry participants, and to learn more about Finetech equipment capabilities and the specific materials needs of the photonics industry,” said Andy Mackie, Senior Product Manager at Indium Corporation.

The general feedback from the participants was how fascinating it was to see and align such small features. Most couldn’t wait to get their hands on the machine and try the alignment process.