Used either as a permanent or as a temporary material within the semiconductor manufacturing processes, glass plays a key role in the semiconductor industry. It is today already implemented as a mature solution, in several market segments such as infrared (IR) cut filter for CMOS image sensor (CIS) technology, microfluidics devices and some actuators and sensors.

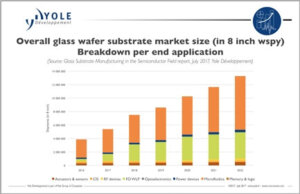

Yole Développement (Yole) confirms the growth of the glass materials market for the next five years. Therefore, the 8-inch eq glass wafer market is expected to increase at a 23% CAGR through 2022, reaching around 14M 8-inch eq. wafer. Related revenue will exceed almost US594$ million by 2022, explain Yole’s analysts. Why will the glass wafer market’s revenue more than double over the next five years?…

Yole’s analysts propose today a new technology & market analysis dedicated to glass materials for semiconductor manufacturing, titled Glass Substrate Manufacturing in the Semiconductor Field. This report provides detailed information regarding the current and potential applicability of glass material in the semiconductor field, as well as its processing functionalities. Analysts also review in this report major applications currently using glass material as well as potential applications that could require glass.

Yole’s analysts propose today a new technology & market analysis dedicated to glass materials for semiconductor manufacturing, titled Glass Substrate Manufacturing in the Semiconductor Field. This report provides detailed information regarding the current and potential applicability of glass material in the semiconductor field, as well as its processing functionalities. Analysts also review in this report major applications currently using glass material as well as potential applications that could require glass.

“Glass is making serious inroads in the semiconductor market, adopting various functionalities within IC semiconductor devices,” asserts Amandine Pizzagalli, Technology & Market Analyst, Advanced Packaging & Semiconductor Manufacturing at Yole. Specific to semiconductors, glass substrates are typically developed in two formats: wafer and panel, and is available in two densities, thin and thick. Moreover, glass can be used in two different ways to fabricate a semiconductor device’s product:

- A glass-based product where the glass material is applied as a permanent material and remains in the final product.

- A non-glass-based product where the glass substrate is only applied for temporary use in the process flow and then removed after the IC device is processed.

Some IC device applications using glass material are mature, such as CIS, microfluidics, and actuators & sensors, with relatively low growth opportunity except for fan-out wafer level packaging (FOWLP) applications driven by glass carrier usage.

Regarding functionalities, wafer-level capping, and permanent substrates, both fueled by the automotive and medical fields, drive the development of the glass wafer market.

The glass material market’s ascent will be due to the fast growth of glass carriers for FOWLP, actuators, and sensors. On the other side, through glass vias (TGV) interposer is still perceived as immature, but Yole is expecting an adoption rate for production by 2019 – 2020.

The glass material market for semiconductor is concentrated amongst glass material suppliers from different categories:

- Raw material manufacturers like Schott, Corning, and AGC providing raw glass material and blank wafers or sheets. These companies have limited wafer-processing capabilities.

- Glass processors and structured substrate manufacturers like PlanOptik and Tecnisco, which can pattern and structure glass wafers from the raw material provided by raw material suppliers. These companies typically purchase wafers from raw-glass material suppliers and then design/create products from the raw material.

- Structured/patterned glass wafer manufacturer mainly from microelectromechanical systems (MEMS) and microfluidics areas, focused mainly on microfluidic and MEMS devices. This category mostly includes foundries that start from blank or pre-patterned wafers. However, contrary to a typical foundry such as Silex Microsystems, these companies create their own products.

Established glass applications such as CIS and microfluidics have led Schott to dominate the glass material market in the semiconductor field. However, emerging applications including RF devices, FOWLP technology and more… could require the use of glass material. These emerging fields represent real business opportunities for some glass companies.

“In the quest to acquire market share, we’re seeing the entrance of aggressive players like NEG in the FO WLP field”, explains Amandine Pizzagalli from Yole. “We also see increased competition, even in mature markets like actuators & sensors and power devices where Chinese glass processor companies are likely to challenge established players like PlanOptik and Tecnisco.”

Increased competition has created a challenging environment for glass substrate makers. This competitive landscape is analyzed in Yole’s Glass Manufacturing report. A detailed description of this report is available on i-micronews.com, manufacturing reports section.

Yole’s analysts are part of SEMICON West agenda with presentations (Click Program) and booth (#7753 ). The team will also attend SEMICON Taiwan (Booth # 828). Feel free to ask for a meeting or visit our team this week. Stay tuned.

Source: www.yole.fr