I’ve been following the progress of wet etch processes for TSV reveal steps, with particular focus on SSEC’s efforts in this area, since I first heard SSEC CTO Laura Mauer present on the topic at the European TSV Summit. At IWLPC 2013, I caught up with SSEC’s VP of Marketing, Erwan Le Roy, to learn more about the company’s recent tool enhancement—the MultiPath Collection Drain—introduced in September at SEMICON Taiwan as a new feature available on the company’s WaferEtch™ platform. This novel chemistry isolation and drain design makes it possible to capture, recirculate, and protect multiple chemistries in the same chamber, resulting in minimal cross-contamination of chemicals and faster switching between chemicals and DI water.

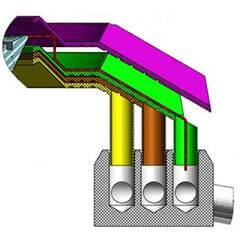

According to Le Roy, the unique design and structure differentiates the MultiPath Collection Drain from conventional drain systems in two ways. First, rather than a single collection point with a drain, there are three trays with dedicated fluid paths stacked on top of each other (Figure 1). Each tray is operated with an independent valve. Secondly, instead of the wafer chuck moving to align with the collection point, the chuck is always aligned with the collection cups, which can be opened and closed to instantly route chemistry to the desired path.

Le Roy says the instant-tray-activation feature allows for improved chemical recovery of multiple chemistries with negligible cross-contamination. “In any etch process–for example, under bump metallization etch (UBM)–it’s critical to control the undercut,” he explained. “With the MultiPath Collection Drain, we don’t have to wait for the chuck and we have better control over the quench process.” A quicker quenching of the etch directly translates to less undercut. “Furthermore,” he added, “the three-tray design allows for different chemistries to be used. For example, the TSV reveal process calls for first using a hydrofluoric acid (HF)\nitric acid (HNO3)-based etchant for bulk silicon removal. Prior to revealing the through silicon vias (TSVs), a rinse step is performed to clear the HF\HNO3 etchant, followed by an etchant that is compatible with the via materials (Cu and SiO2). The second etchant is typically highly alkaline, as opposed to the bulk silicon etchant, which is highly acidic. With the MultiPath Collection Drain, not only are the chemistries and rinse recovered by different pipes, there is no longer the need to have two separate chambers to accommodate different chemistries, which, if inadvertently combined would create ‘rocket fuel’,” explained Le Roy. The three-pipe drain system allows for the recirculation of chemistries within the same chamber through fume mitigation and substantial reduction of cross-contamination.

In addition to better process control and minimal cross-contamination, Le Roy says the system lowers the cost of ownership, which is good news for those looking to reduce costs of 3D TSV process steps. ~ F.v.T.