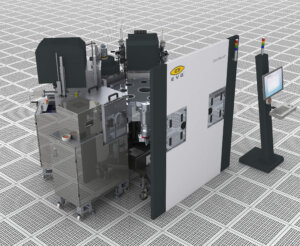

EV Group (EVG), a leading supplier of wafer bonding and lithography equipment for the MEMS, nanotechnology and semiconductor markets, today announced that IHP – Innovations for High-Performance Microelectronics (IHP), a German research institute for silicon-based systems, highest-frequency integrated circuits, and technologies for wireless and broadband communication, has purchased an EVG® ComBond® automated high-vacuum wafer bonding system for use in developing next-generation wireless and broadband communication devices.

The EVG ComBond features micron-level wafer-to-wafer alignment accuracy and room-temperature covalent bonding, which enables a wide variety of substrate and interconnect combinations for producing advanced engineered substrates, next-generation MEMS and power devices, stacked solar cells, and high-performance logic and “beyond CMOS” devices. The ability to conduct oxide-free aluminum-to-aluminum (Al-Al) direct bonding at low temperature is a unique capability of the EVG ComBond platform and is among the new bonding applications that IHP will explore with the system.

Covalent bonding enables wafer-level packaging and heterogeneous integration

Heterogeneous integration through wafer-level-packaging (WLP)—where multiple semiconductor components with different design nodes, sizes or materials are combined into a single package at the wafer level—is key to extending the semiconductor technology roadmap. Metal and hybrid wafer bonding are key process technologies for WLP and heterogeneous integration due to their ability to enable ultra-fine pitch interconnections between the stacked devices or components. The continuous drive to higher performance and functionality of these integrated systems requires constant reductions in the dimensions and pitch of the interconnects—which in turn drives the need for tighter wafer bond alignment accuracy.

In addition, for certain WLP applications, Al-Al direct bonding is a promising new method of metal-based bonding due to aluminum’s low cost coupled with its high thermal and electrical conductivities. However, conventional Al-Al thermo-compression bonding requires high temperatures and bond forces to provide reliable bonding interfaces—making it incompatible with heterogeneous integration efforts.

According to Paul Lindner, executive technology director at EV Group, “Combining different materials and device components into a single package has taken on greater importance in adding performance and value to electronic devices. The EVG ComBond facilitates the bonding of nearly ‘anything on anything’ in wafer form. This provides our customers with a powerful solution for researching new material combinations for future semiconductor devices. Its micron-level alignment capability also makes the EVG ComBond uniquely suited for use in high-volume manufacturing of emerging heterogeneous integration device designs.”

EVG’s breakthrough ComBond wafer activation technology and high-vacuum handling and processing allow the formation of covalent bonds at room or low temperature for fabricating engineered substrates and device structures. The EVG ComBond facilitates the bonding of heterogeneous materials with different lattice constants and coefficients of thermal expansion (CTE) as well as the formation of electrically conductive bond interfaces through a unique oxide-removal process. The EVG ComBond maintains a high-vacuum and oxide-free environment throughout the entire bonding process, enabling low-temperature bonding of metals, such as aluminum, that re-oxidize quickly in ambient environments. Void-free and particle-free bond interfaces and excellent bond strength can be achieved for all material combinations.

For more information on the EVG ComBond, visit: https://www.evgroup.com/en/products/bonding/waferbonding/evg_combond/