3D InCites / 3D+ recently had the opportunity to visit Dr. Robert Andosca, co-founder, president, and CEO of MicroGen Systems, Inc., at MicroGen’s headquarters in the High Tech Rochester Lennox Tech Enterprise Center, just off the Rochester Institute of Technology campus in Henrietta (Rochester), NY.

To devotees of film, particularly the 35mm variety, Rochester will be fondly remembered as the home of Eastman Kodak, who “owned” the photographic film market for more than a century.

Kodak today, now transformed into a technology company focused on imaging applications and products for business enterprises, is, according to The New York Times, also working on “… nanoparticle wonder inks, cheap sensors that can be embedded in packaging to indicate whether meats or medicines have spoiled, and touch screens that could make smartphones cheaper.”

That’s something of a monumental pivot for this particular industrial giant. And also something of an indication of how deep the roots of innovation are in Rochester, and how innovative the Rochester area remains today.

Need proof that Rochester innovates with the best of them? Just look at MicroGen.

According to their website, MicroGen Systems, Inc. is “… the global leader in designing and manufacturing nanotechnology/MicroElectroMechanical Systems (NEMS/MEMS) micro-power and micro-sensor products for wireless sensor and mobile electronics applications. Founded in 2007, MicroGen is privately held with corporate headquarters and development facilities in the Ithaca and Rochester, NY areas, and volume manufacturing in Itzehoe, Germany. MicroGen developed its baseline piezoelectric vibrational energy harvester (PZEH) technology at Cornell University within the Cornell NanoScale Science and Technology Facility. Now, MicroGen’s PZEH and piezoelectric platform technology for piezoelectric sensor integration is being transferred to X-FAB located in Germany, Malaysia and the USA. X-FAB is world renowned for its microelectronics and MEMS technology foundry production capabilities.”

Ithaca, Itzehoe, Rochester; but what I saw first, entering MicroGen HQ the morning of my visit, was tires.

In an office rich with show-and-tell displays, it’s the truck tire that makes an immediate impact on the visitor, maybe because it’s a big tire, and maybe because a tire is not what the visitor expects to see on a high-tech tour in Rochester. (Unless it would have been the tire from a flying car, that is.)

But it begins to make more sense once Robert starts explaining.

A rolling truck tire, when the truck of which it is part is moving, generates a very specific impulse (or vibration) signature, a signature that is a function of rotation speed, the tire’s inflation pressure, the condition of the tire’s tread, and the road condition, among other factors.

In that dynamic environment, the rolling tire’s, there is both an abundance of “free” energy that could possibly be harvested for some useful task, and there is also an abundance of useful information that could possibly be collected and analyzed and then used to make decisions about things like remaining tire tread life, the need for a retread, etc.

How great would it be if there was a sensor, a Tire Pressure Monitor Sensor/System, powered by energy harvested from the rolling tire, and, using the tire vibration signature, continuously reporting on tire health – e.g. tire pressure, yes, but also information about useful tread life, or wear abnormalities? Or even traction quality between the tire and the road?

How great would it be if a car losing traction due to black ice (it’s Rochester, remember), was able to make that determination in a split second thanks to its MEMS energy harvesting / sensor fusion technologies, correct for the skid, and at the same time send that information (black ice here!) to all vehicles in the immediate area, behind and in front, so that those vehicles could anticipate the unsafe conditions before they are on top of them?

That would be very great, and it would also be … exactly the kind of products MicroGen is bringing to market.

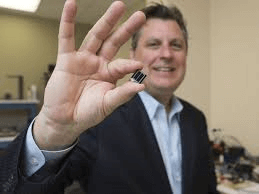

MEMS energy harvesting and sensor fusion in one product. Indeed, in one chip. The TPMS market is but the tip of the iceberg for where this could go.

Somewhere in the near future there will be a convergence of low-power sensing devices and energy harvesters, a fusion, so to speak, and a disruptive enabling technology, that will be reporting not just from truck and automobile tires, but potentially from anything that moves or vibrates, whether that anything was designed to move or vibrate, or not. (Think of an ever-vigilant “sentry” waiting in the wings.)

The MicroGen team, lean and deeply experienced, is continuing to attract notice, continuing to attract investments, and continuing the commercialization of miniature, autonomous, perpetual power supply solutions for wireless sensor and sensor fusion applications.

Tires draw your attention, but future possibilities hold it. In the long run, there will be “Generations of Power.” And energy harvesters, sensors, power converters, and radios heterogeneously integrated into something wonderful.

And that’s a great thing.

Dr. Robert Andosca and Dr. Kathleen Vaeth from MicroGen will be speaking at the Sensors Expo & Conference 2015 on 09 June 2015 and again on 11 June 2015. Join Robert, Kathleen, MEMS Industry Group, 3D InCites / 3D+, and others in Long Beach, CA for the 30th annual Sensors event.

From Pittsburgh, PA, thanks for reading. ~PFW