X-Ray inspection has become an essential component in semiconductor manufacturing, with 3D imaging emerging as a critical tool for ensuring product quality and reliability. In a recent discussion with Andrew Mathers, Principal Product Line Manager at Nordson Test and Inspection, we gained valuable insights into how advancements in 3D x-ray imaging are revolutionizing the inspection process in semiconductor and surface mount technology (SMT) manufacturing.

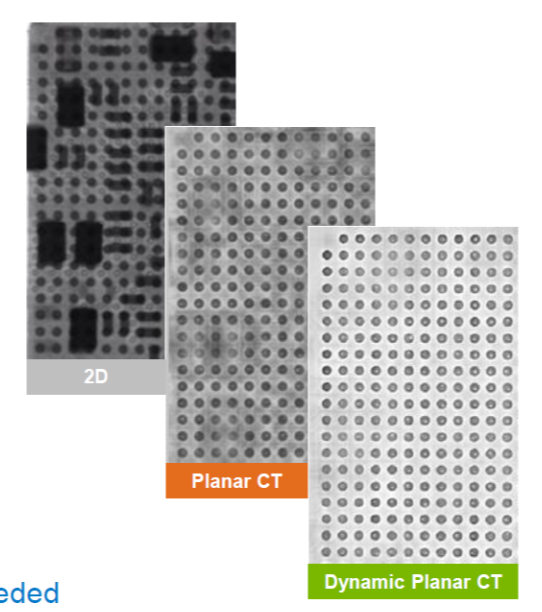

Traditional inspection methods have relied heavily on 2D radiographic imaging, which, while useful, has significant limitations when examining today’s increasingly complex electronic components. As manufacturing requirements become more stringent and quality expectations rise, 3D imaging has emerged as a superior alternative. However, implementing effective 3D imaging for electronic components presents unique challenges that Nordson has addressed with its Dynamic Planar CT technology.

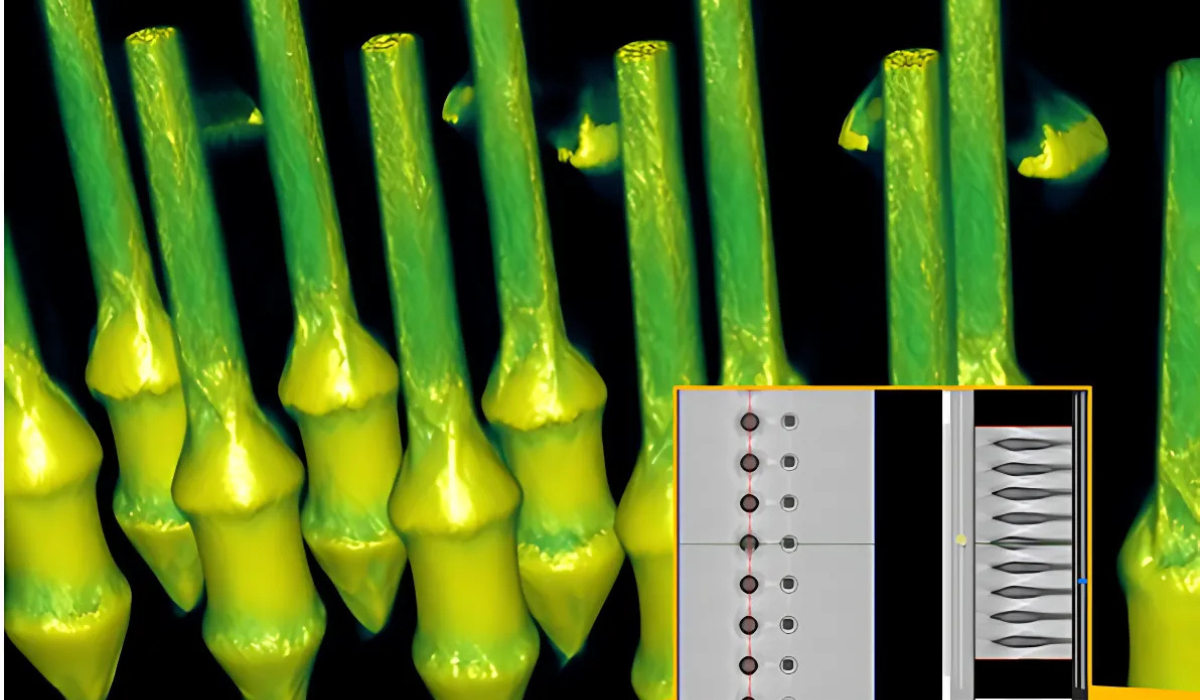

Electronic components like semiconductor wafers and printed circuit boards are inherently flat or planar objects. Traditional 3D imaging techniques using planar CT or laminography often introduce artifacts – distortions in the resulting images that don’t actually exist in the sample. These artifacts make it difficult to distinguish between different layers and to identify defects clearly. Mathers explains that while 3D imaging has been available in electronics for some time, the quality has been difficult to achieve due to these inherent challenges with planar samples.

Dynamic Planar CT, Nordson’s next-generation 3D inspection technology, addresses these challenges through both hardware and software innovations. The system takes a fundamentally different approach to image acquisition, capturing more projections from different angles with a wider field of view and implementing advanced reconstruction algorithms. The result is a much higher quality 3D model that significantly reduces artifacts and provides clearer discrimination between layers (Figure 2). Most impressively, this technology operates at twice the speed of traditional planar CT, enabling much higher throughput – a critical factor in manufacturing environments where inspection can’t become a bottleneck.

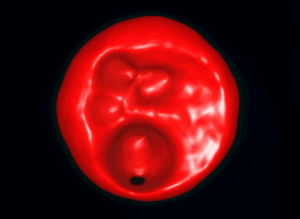

One of the key benefits of Dynamic Planar CT is its ability to identify critical defects that might otherwise go undetected. In semiconductor back-end processing and SMT manufacturing lines, the technology excels at detecting voids in ball grid arrays, micro bumps in flip chip devices, and other defects that could compromise product performance. By identifying these issues early in the manufacturing process, manufacturers can pull affected components before further processing, preventing costly failures down the line and ensuring only high-quality products reach the end customer.

Beyond simply identifying defects, the technology supports Quality 4.0 and Industry 4.0 initiatives by providing feedback that can be used to improve manufacturing processes. Rather than just flagging the same defect repeatedly, the system can report back to the manufacturing process in a connected smart factory environment, enabling real-time adjustments that address the root cause of defects. This continuous improvement mechanism helps manufacturers maintain consistent quality while minimizing waste and maximizing efficiency.

Nordson’s automated x-ray inspection (AXI) solutions are designed for high-volume manufacturing environments where speed, resolution, and reliability are paramount. With systems tailored for semiconductor, SMT, power hybrid, and final assembly markets, the company supports a wide range of electronic manufacturing applications. With a global presence in over 35 countries and more than 2,000 AXI systems installed worldwide, Nordson has established itself as a leader in this critical inspection technology.

As electronic components continue to become more complex and compact, the role of advanced inspection technologies like Dynamic Planar CT will only grow more important. Manufacturers who embrace these technologies will be better positioned to deliver high-quality products consistently while maintaining the efficiency needed to remain competitive in today’s fast-paced markets.

Learn more in our recent podcast episode featuring Andrew Mathers here.