The quick answer to the question; “Is the semiconductor industry becoming more sustainable?” is “yes and no.” There is undoubtedly more talk about sustainability and environmental impact, especially from the larger companies in our industry. In 2022, SEMICON West devoted an entire day to the topic for the first time. Awards recognizing companies for sustainability are popping up, including one from 3D InCites that started in 2021.

But progress sometimes feels incremental, and it isn’t necessarily reaching throughout the supply chain. Data show progress toward sustainability goals to back up the talk. Companies in the semiconductor industry are considering environmental impact when making decisions. Are they doing enough to become more sustainable? Let’s take a look.

Climate Change and Sustainable Water Security

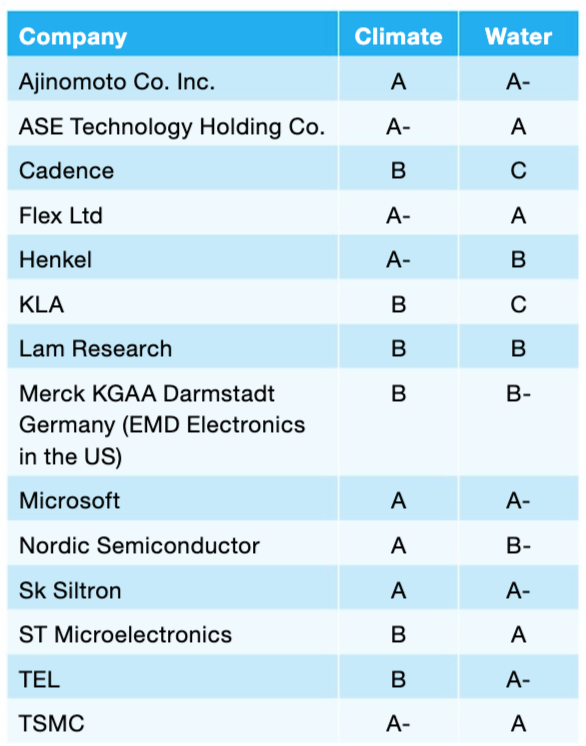

One way to gauge the industry is to examine CDP scores on climate change and water security. (CDP also has a category for forests, but since semiconductor manufacturing doesn’t use a lot of pulp and paper products, that isn’t as relevant.)

Table 1 shows 2022 scores for 3D InCites community members, along with other industry leaders that scored an A (the highest ranking) in either climate or water. Ajinomoto and ASE are the only community members to achieve an A. Henkel and TEL are just a little behind. Scores from some members that submitted data were unavailable on the CDP website as of December 2022.

It is nice to see the semiconductor industry represented among the nearly 300 companies that made the A list for the climate. It would be better to see more companies up there in 2023 and beyond.

Examining the 3D InCites Community

Companies tend to focus on their small piece of the industry. That makes sense because it is what they know best. We can get a more holistic and complete view by looking at what peers, competitors, and suppliers are doing to become more sustainable.

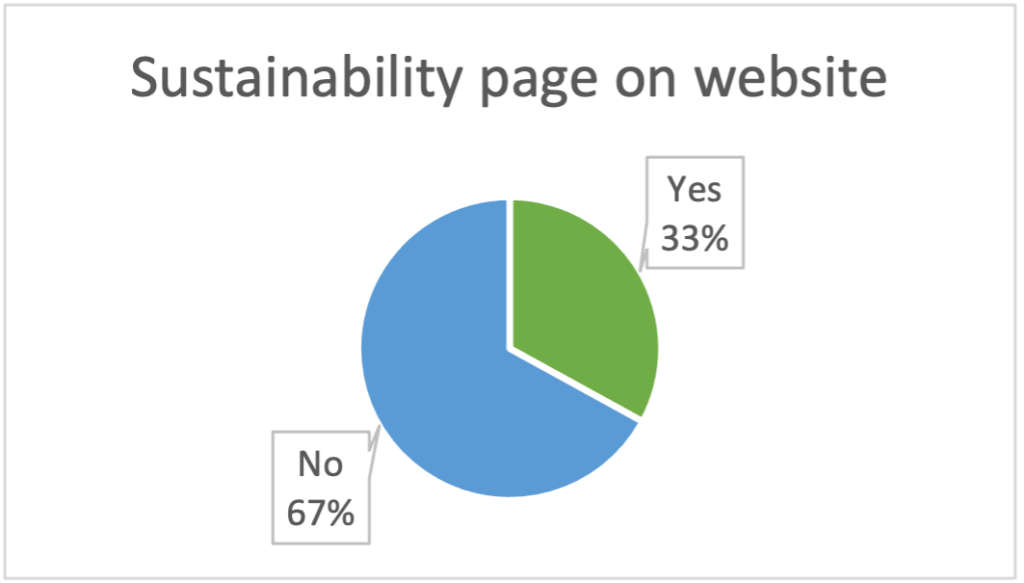

Members of the 3D InCites community represent companies of all sizes and from various sectors, including assembly, design, materials, and equipment. The 56-company list (58 when this was written) is a snapshot of the semiconductor industry with a focus on packaging. I looked up the member companies to find out what they are saying and doing about sustainability.

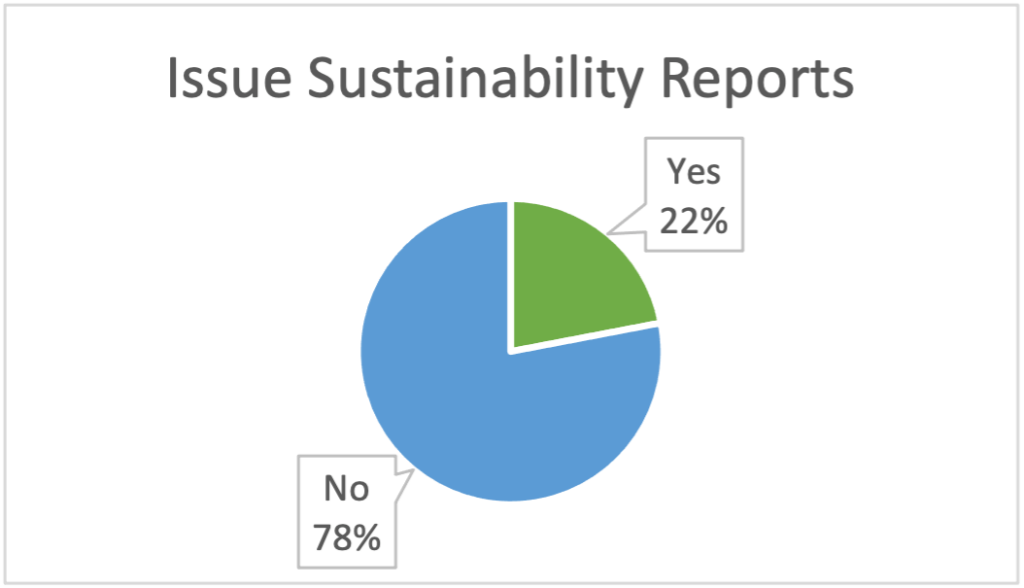

Sustainability discussions are becoming more common, but only some are talking. Only one-third of 3D InCites members have a sustainability page on their websites. Even fewer members—22%—issue annual sustainability reports or something similar (Figure 1).

Sustainability reports are often dense documents, with 100 to 200 pages of data and text. Diving into the reports can be confusing. Sometimes data from one section appears to contradict data from another section. I would like to see clearer, more consistent messages. I shouldn’t need a conversation with the report authors to determine whether greenhouse emissions decreased or if a reported drop included abatements or offsets.

Progress on Sustainable Emissions

The companies that issue reports have all reduced greenhouse gas (GHG) emissions per quantity of product or revenue. Some have achieved absolute reductions, which are needed to get to zero emissions. ASE, for example, reported a 3% drop in Scope 1 and Scope 2 emissions from 2020 to 2021 despite nearly 20% revenue growth. That demonstrates significant efficiency improvements, yet the net decrease is still tiny.

Several companies say they intend to achieve net zero emissions by 2040. That goal sounds concrete. The problem is that the path to get there is not clear. The first 20 percent is much easier to cut than the last 20 percent.

Most of the progress is in Scope 1 and Scope 2 emissions. Companies admit that the bulk of emissions are indirect, or Scope 3. Downstream emissions come from using the company’s products, which is the most significant contribution for equipment manufacturers. Upstream Scope 3 emissions come from purchased components, materials, and chemicals. Full traceability extends to the extraction and manufacturing of raw materials.

Working with suppliers can help reduce upstream emissions, but control rarely reaches further than one step up the supply chain. As LPKF notes in its sustainability report, “We are as yet unable to comprehensively monitor or control the upstream links in the supply chain.”

Waste and Recycling

Henkel states a 2030 goal of “100% of packaging designed for recyclability and reusability” with a caveat. They exempt products where ingredients or residue may affect recyclability or pollute recycling streams. I appreciate the awareness and desire not to pollute recycling streams. What is the plan for those products?

LPKF plans to increase the use of recyclable materials to 80% by 2030. The company is also working to reduce the use of hazardous substances through its annual substitution survey. The goal is to switch to less harmful alternatives wherever possible.

Veeco admits that its waste data is incomplete. It focuses on hazardous waste and does not include office waste or materials sent for single-stream recycling. The company plans to account for its complete waste stream in future reports.

I appreciate the growing awareness of challenges around waste management, including the desire not to pollute recycling streams. I also hope a more comprehensive accounting for waste will highlight the importance of creating less of it. Reuse is always better than sending out hazardous or nonhazardous waste for recycling.

The Upshot

GHG emissions and waste management are only two critical aspects of environmental action. There are signs of progress in other areas. Water reclamation and recycling are on the upswing. Companies are considering how their operations contribute to biodiversity loss and ways to mitigate the impact. The connection between diversity, equity, and inclusion (DEI) and employee engagement around sustainability is building.

My research has revealed progress and also gaps. Awareness about how environmental impact relates to each company’s operations has not yet spread throughout the semiconductor industry. Perhaps connections through the 3D InCites community can help broaden the reach.