It was cold, a bit overcast, and I was headed to a SEMICON show in December. Usually, this would mean SEMICON Japan, but this was SEMICON West Hybrid 2021 during the second week of December in San Francisco.

SEMI made the decision with its members last February to have SEMICON West in early December, with Japan to follow a bit later. It was hoped that both these events would be hybrid, with more face-to-face interaction than video attendance, and the potential for collaboration.

![]()

Unfortunately, the Omicron variant of the COVID-19 Virus put a major kink into those plans, as travel to and from Asia was essentially shut down, and while there was a significant European attendance from vendors and imec, many companies chose to send smaller teams to attend the show. Some presenters chose to use the hybrid technology and present remotely, either by their choice or company recommendation.

While the downside was smaller crowds and fewer booth interactions, the upside was that the interactions had higher value and meaning, and you could easily get a seat at the keynote and other presentations. In polling several sales and marketing staff from different companies, they all responded that the meetings were of high quality and value, and most importantly it was great to see and meet with people face-to-face.

As the SEMICON shows roll on, SEMICON Japan and Taiwan will likely have few foreign visitors due to quarantine restrictions. The same may hold true for SEMICON Korea. In quizzing marketing principals about show participation, and booth setup; it became apparent that the regional marketing teams at most companies play a bigger role than they have in the past of putting on their local SEMICON show, which is great because in one way or another the shows will go on!

On to SEMICON West Hybrid 2021

SEMICON West has evolved over the years — from the week before Memorial Day weekend at the San Mateo Fairgrounds, with a focus on equipment process and Beer Gardens — to July in San Francisco with topics not just related to the semiconductor manufacturing space, and networking events to help the industry collaborate better. It now even includes weightier topics that address the human condition such as diversity, equity, and inclusion and those that impact the health of the planet such as sustainability.

SEMICONs have always had a strong technology focus. This year, imec started off the show on Monday night with a networking event that was relatively well attended. Luc van den hove President and CEO of IMEC provided an overview of some key programs. I’ve addressed the sustainability focus in another blog.

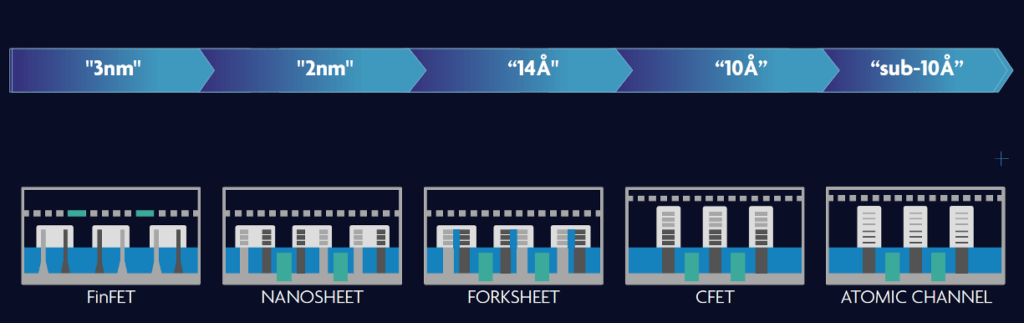

From a technology focus, imec’s programs help drive the industry to the next technology node. Since before imec’s instrumental work in high-k metal gates for logic, they have helped to drive cooperation and competition in both memory and logic chip development. Van den hove laid out the current technology roadmap taking place at imec to help the industry move to the sub-nanometer nodes, including lithography and 2D materials.

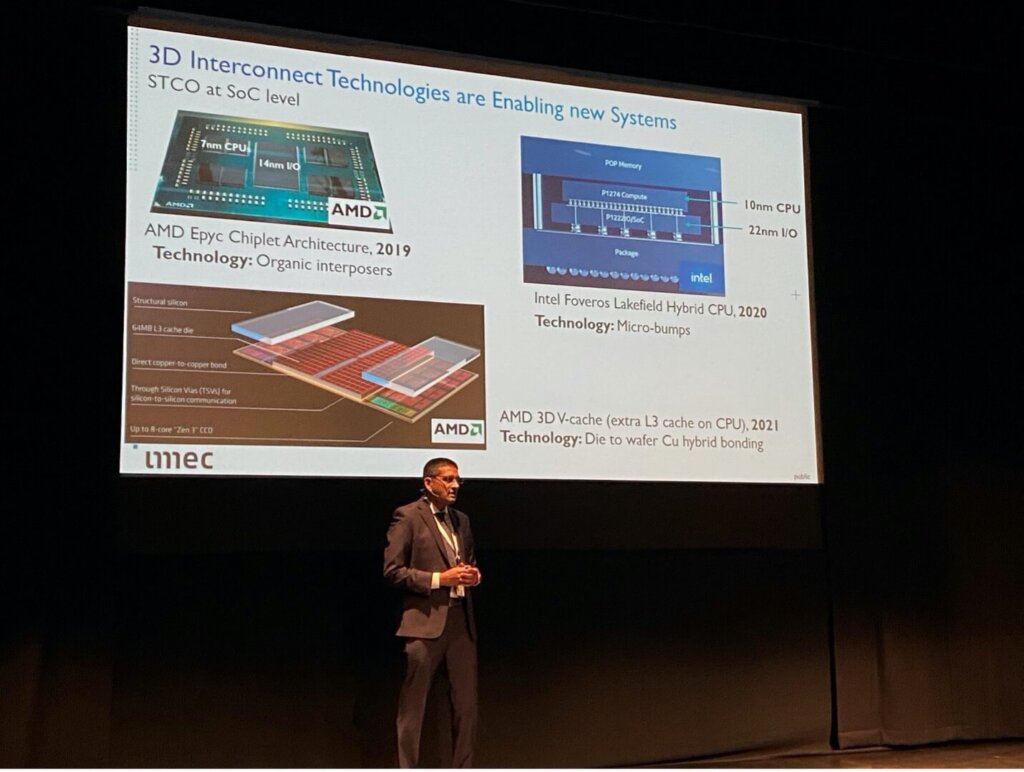

Sri Samavedam, senior vice president of CMOS technologies, gave a bit more detail on imec’s technology programs. From the 3D perspective, Samavedam covered interconnect as well as what is taking place in heterogeneous integration.

Samavedam pointed out that shrinking the interconnect and bump pitch will be critical in shrinking the 3D packages, and that figuring out how to partition the memory better will help to reduce the power consumed in the advanced systems used for AI and edge computing.

From The Keynote Stage

Tuesday dawned and while expecting crowds and possibly a wait to get into the show, the longest delay was fumbling for my ID and vaccine card. Dave Anderson was moderating the keynotes and had a very entertaining arrival. I think it is worth watching if you are still viewing the show virtually.

The keynotes at SEMICON West Hybrid 2021 covered the gamut of the supply chain, technology, DEI, collaboration, and innovation nearly before you finished your coffee, so there was a nice diversity of topics each day.

The Chips Act

The first keynote featured a conversation between Ajit Manocha, President, and CEO of SEMI; and Don Graves, Deputy Secretary, U.S. Department of Commerce, regarding the Chips ACT. Manocha kicked off the conversation by commenting on the unprecedented cooperation between the commerce department, SEMI, and the industry, and pointing out that we are at an inflection point in the global economy, as well as the entire micro-electronics eco-system.

Graves highlighted the CHIPS Act, which will enable long-term investment to bring chips back to the US and build the manufacturing infrastructure needed. Graves says he thinks the top priorities include:

- Passing the $50B Chips Act through Congress. This will drive innovation and bring chips manufacturing back to the US.

- Developing an early alert system – however, Graves did not elucidate on this topic

- Having conversations to develop better policy and give us more predictability in the semiconductor market.

- Figuring out how the semiconductor industry can improve collaboration with the DOC

- Deciding how to best strategically invest the dollars from the CHIPS Act — although NIST already has some ideas I’ll discuss later in the blog.

- Creating a healthy ecosystem and supply chain

On this one, I scratched my head, as while the supply chain is currently struggling as a result of shipping and supply issues resulting from the pandemic, the industry has had a fairly healthy worldwide eco-system. If the DOC wishes to develop an in-country eco-system, this will need to be the first of many $50-billion-dollar infusions to the American semiconductor business.

A few other notes from the discussion I thought were pertinent:

- 12% of the chips are currently made in the USA. The US Government needs to provide incentives to create jobs and manufacture chips in the U.S. They are not saying it all needs to be done here. We need to work with partners around the globe to be successful. For instance, TSMC and Samsung are investing here. But the government needs to help to incentivize US companies to invest here like other countries incentivize to keep the IC industry strong in their countries.

- We need to develop the workforce and create a workforce pipeline for both technology development and manufacturing by creating STEM programs that go back at least to middle school.

I personally would suggest earlier than middle school, as by then in many cases the die is already cast. Additionally, I would take this a step further and see how to further break down the digital divide, to reach into communities that may not have access to STEM or technology until much later in life.

- DOC is working through the data which will help to inform what steps are needed to take. The DOC needs to be transparent, understand the challenges, and what is going on in the supply chain.

Having been the recipient of a DARPA program grant back when the U.S. dominated the chip industry, this looks like a good start. I appreciate the fact that the DOC is looking for transparency and effective communication on this topic. And I, like Ajit hope it’s just the first of at least a few $50 billion dollar packages.

Managing Innovation

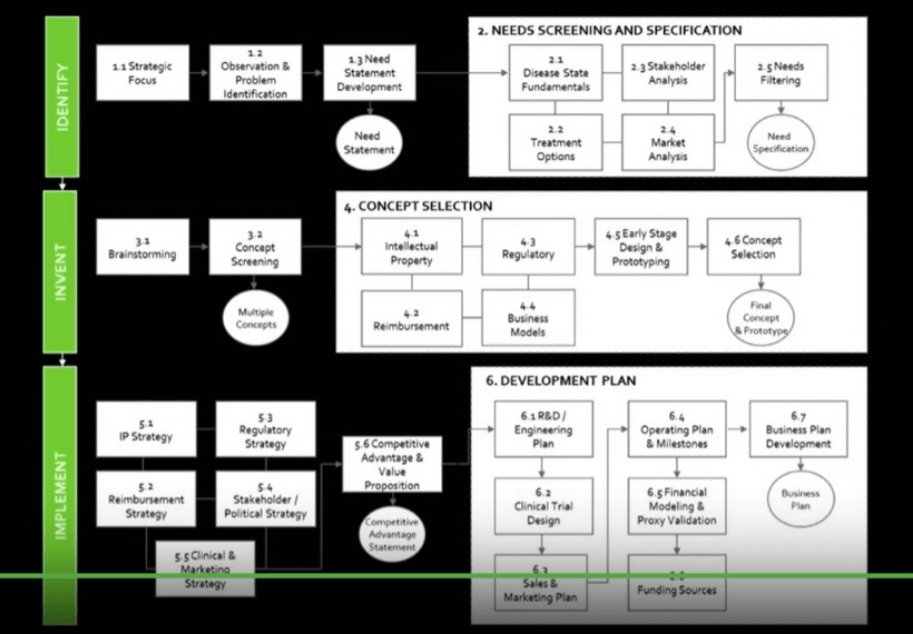

Josh Makower Professor, Stanford University School of Medicine, Director of Stanford Beyers Center for Biodesign, Founder and Executive Chairman, ExploraMed presented on Biodesign: The process of innovating New Breakthrough Medical Technologies.

Makower discussed how during his career he discovered that once startups were acquired, the level of innovation dropped off. As a result of his findings and additional experience throughout his career, he developed the Biodesign process, which defines or identifies the need and then moves through the development phases to go or no go.

Having been involved in a significant number of development projects, as well as watching companies develop and then grow ideas, having a template that has been used very successfully can be extremely helpful in delivering product and innovation. The Stanford Beyers Center for BIODESIGN has trained over 3000 individuals, and approximately 80 companies have been created.

Know Your Supply Chain

As the supply chain is currently at the center of many issues. SEMI had a panel with James Gellert, the Chairman and CEO of Rapid Ratings, and Bindiya Vakil Founder and CEO of Resilinc. The panel discussion touched on the basics of supply chain management, and the need to map your supply chain, and to be aware of crises in different parts of the world. Vakil explained that understanding where your supply chain has its manufacturing sites, not just where they are headquartered, is critical. That way if you have a natural disaster in a certain part of the world you are aware you may have a problem and can follow up.

Both Gellert and Vakil cautioned that it is critical to have a deep understanding of your suppliers from aspects such as financial, manufacturing capability, and resilience to managing challenging situations. Failure to do so could result in unexpected surprises.

On Wednesday Gellert presented on, The Second Wave: Risk in Part Two of the Supply Chain Crisis. This approach views the companies from a financial status. Gellert pointed out that companies are more leveraged than ever due to cheap capital. The cheap capital has masked financial risk and there could be a shock to the supply chain if a company ends up failing. To hear more about what Gellert had to say, listen to this 3D InCites podcast interview.

This is only a snapshot of the presentations and interactions that took place this year at SEMICON West. While attendance was lower than expected due to unforeseen circumstances the quality of the event and the face-to-face interactions made SEMICON West Hybrid 2021 memorable.