It all started with a Rubik’s Cube…

When I was in middle school, I liked to struggle with new concepts and would look for ways to challenge myself. It was during this time that I found what became my ongoing project (and some might say obsession), the Rubik’s Cube. I spent an entire night teaching myself to solve the original 3x3x3 Rubik’s Cube, and my fate was sealed. The 3x3x3 lead to the slightly larger 4x4x4 Cube, and then to the 5x5x5, all the way to the 7x7x7 Cube, with 218 moving pieces to solve.

In 7th grade, when I let a classmate play around with the cube, a piece came loose, causing the entire mechanism to fall apart. That weekend, I spent hours putting it back together, and I was shocked about how difficult it was. I watched YouTube videos, asked my parents for help, visited various forum pages – you name it – until I finally figured out how to reassemble it. Once that last piece smoothly went in, my sense of satisfaction was through the roof! I felt so accomplished being able to create a moving mechanism from what seemed like a bunch of random shapes, and I think that this was truly the first step on my journey into mechanical engineering.

As a freshman in high school, I was introduced to 3D modeling software: Autodesk Inventor. I wasn’t satisfied learning how to create different shapes and simple dimensioning; I knew I could do more, and I dove into learning the software on my own. For my final project in that class, I created a fully functioning model of the original 3x3x3 Rubik’s Cube in Inventor. This was a great challenge for me because I learned a ton about the mechanism of a Rubik’s Cube and how it works together to function. In an engineering class at a local community college during my high school senior year, I recreated the Rubik’s Cube model again in SOLIDWORKS, another 3D printing software. Creating the model in the program wasn’t enough, however; I wanted to print a functioning 3D prototype. I researched the mechanisms inside the high-end Rubik’s Cube brands to create the best possible Rubik’s Cube that I could. After struggling with a couple of different ideas, I designed and manufactured one of the smoothest Rubik’s Cubes that I still own today.

By this point, I knew I wanted to study engineering in college, but I still had to choose a discipline within the field: I loved learning about mechanics, but I was also fascinated by chemistry. This led to a lot of thought and debate as I tried to settle on a specialty. In the end, I chose mechanical engineering, because it’s broader, and I knew that it would introduce me to many more fields in engineering. After making that decision, I chose Arizona State University, because its strong mechanical and chemical engineering program would allow me to focus on mechanical engineering and provide me with a backup plan if I wanted to change to chemical engineering.

And EVG has brought me to MEMS (and more) …

Junior year at ASU is the time to investigate internships that will help students pick a career path to enter after graduation. I wanted to look for something that had major mechanical engineering concepts, but also included chemical engineering. My research led me into the semiconductor industry. The industry’s critical placement in today’s world, as demonstrated recently by the well-publicized chip shortage and growth of 5G, the Internet of Things, and the rise of Smart Cities, showed me that the semiconductor industry would have both the job security and the life-long opportunities for growth and problem-solving. This industry combines both my passions: a strong side of looking at the mechanics of all the expensive and large machines, as well as chemicals and chemical reactions. I was convinced that I wanted to have an internship in the semiconductor industry.

EV Group (EVG) was the first company I came across in my research. I talked to a couple of different people from EVG at various career fairs, learning that a previous intern was also a mechanical engineering student like me, and I began to feel that EVG was the place for me. Additionally, EVG appeared to be both progressive and inclusive in its business culture, especially within the STEM community. By maintaining a calm work environment and the reassurance that we are a family, EVG is consistently ensuring that everyone feels that they belong and are valued and supported. Another thing that impressed me at EVG is the near balance between male and female engineers in the technology department. It is humbling to see a real effort to include women in STEM, rather than it being such a male-heavy industry. All that won me over towards EVG, and it’s why I decided to apply for the internship here.

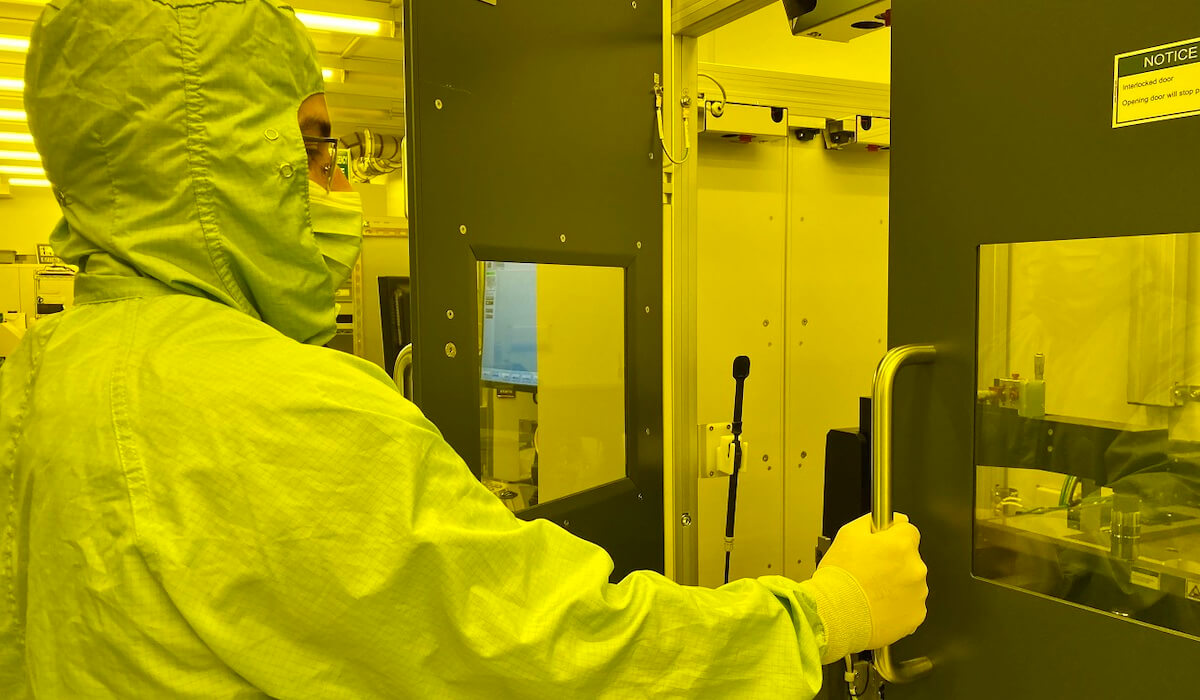

My time at EVG has been challenging, fun, and eye-opening. I look forward to coming to work and learning everything there is to know about the semiconductor industry. My days are spent in the cleanroom, working hands-on and side-by-side with EVG process engineers. I’ve been part of the team, solving complex puzzles in real-world customer applications, learning about the chemistry in the cleanroom, and about how all these big and technical machines work. I’ve been shadowing processes for actual customers, as well as running test samples of my own, making me feel that I am truly contributing to the team at EVG. My co-workers are kind, fun, and everyone is always helping each other out. One of the goals for my internship was to experience the industry, in a real way, and EVG has delivered on that and more. I can confidently say that my experience at EVG has been the perfect application of my education at ASU. I have taken what I have learned in my undergrad and applied it to the major concepts in my internship. It’s changed how I view the engineering field and I love that I have found a new passion that is certainly not going away anytime soon.

A Classic 80’s toy, the Rubik’s Cube, fueled my passions of struggling with new concepts, wanting to challenge myself, figuring out how things work, and designing better, more mechanically functional objects. Now, I’m about to graduate from Arizona State University as a Mechanical Engineer, and I’m excited to see where my adventure with EVG will take me.