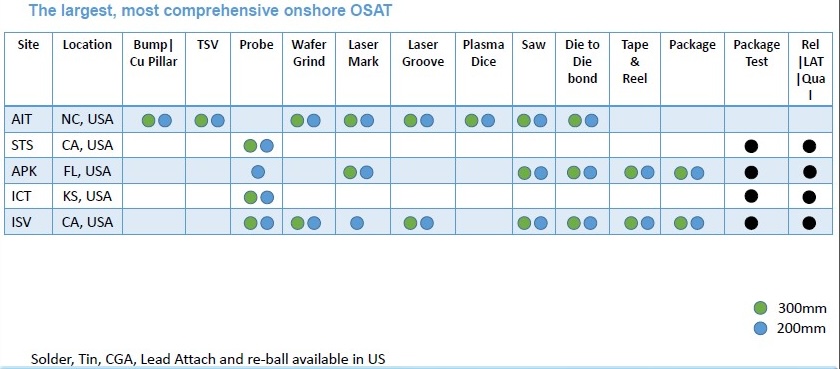

Continuing our look at program information deemed “OK for public release” at the recent IMAPS Onshoring conference, let’s examine what Micross had to say about progress on its Re-shore Ecosystem for Secure Heterogeneous Advanced Packaged Electronics (RESHAPE) 300mm bumping line, sponsored by DARPA’s Industrial Base Analysis and Sustainment (IBAS) program.

Background

Micross acquired its North Carolina site from RTI International a decade ago. Before that. the site was known as MCNC (the Microelectronics Center of NC). This gave Micross its first access to commercial bumping capability, since Amkor Technology had licensed the MCNC plated bumping process from the MCNC spin-out Unitive, and Amkor had, in fact, been running small production lots in the MCNC/RTI fab, albeit on 200mm commercial equipment. When Amkor later left the NC site, the 200mm equipment was transferred to RTI and then on to Micross.

Thus 200mm production bumping has been practiced for ~ 25 years at this site and all that was lacking from putting a 300mm line in place was funding. When IBAS put out their RFP listing, among other technologies, a 300mm bumping capability, Micross bid and won this program.

After the acquisition, this RTP site became part of the Micross AIT (Adv Interconnect Tech) operation. The recent acquisition of Integra has now given them access to world class testing capability.

Project SCAPEx: Secure Center for Advanced Packaging Excellence

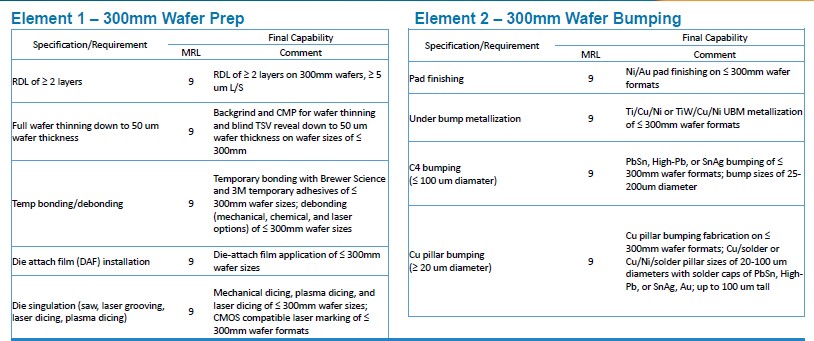

The project goal is to establish secure, onshore 300mm wafer bumping and wafer prep capability accessible to the DoD/DIB and commercial customers. Project duration was 60 months starting in Jan 2024.

- Toolset will be backward-compatible to 200mm

- Micross sites are already “trusted” and ITAR registered

Final capability specs are shown below:

As of Nov 2025

- The facility has been remodeled to be able to accept the new tools

- All of Element 1 and 2 tools have been ordered and are in the process of being delivered and qualified.

Next Step include:

Processing

- Finish installation and qual of tools

- Qualify wafer bumping line

- Begin development of PDK

Customer engagement:

- Continue discussions with customers to queue up customer specific qual lots

As the 300mm line is finished Micross envisions the following offerings:

For all the latest in Advanced Packaging stay linked to IFTLE……………….