Sustainability has become one of the key focus points for the semiconductor industry. When the big customers/users of chips – Apple, Google, AWS, META, and Microsoft – started to look at how to manage scope 3 emissions, they mandated semiconductor companies to work to meet net zero by 2040 or earlier. As a result, this also trickled down to the semiconductor equipment and materials manufacturers.

While many of the larger semiconductor companies have had programs in place for many years and have had key semiconductor equipment vendors working with them to reduce emissions, the broader industry and many sub-suppliers were at a loss for where to start. Enter SEMI to start working and organizing standards, and educating the industry on how to address sustainability.

Sustainability Startup Movement

However, while SEMI was determining how to address sustainability, an interesting grassroots sustainability movement was forming. Intel, Micron, Samsung, Applied Materials, ASML, Lam Research, TEL, KLA, and EMD venture arms were looking for sustainability startup companies to help them solve their sustainability issues and potentially invest.

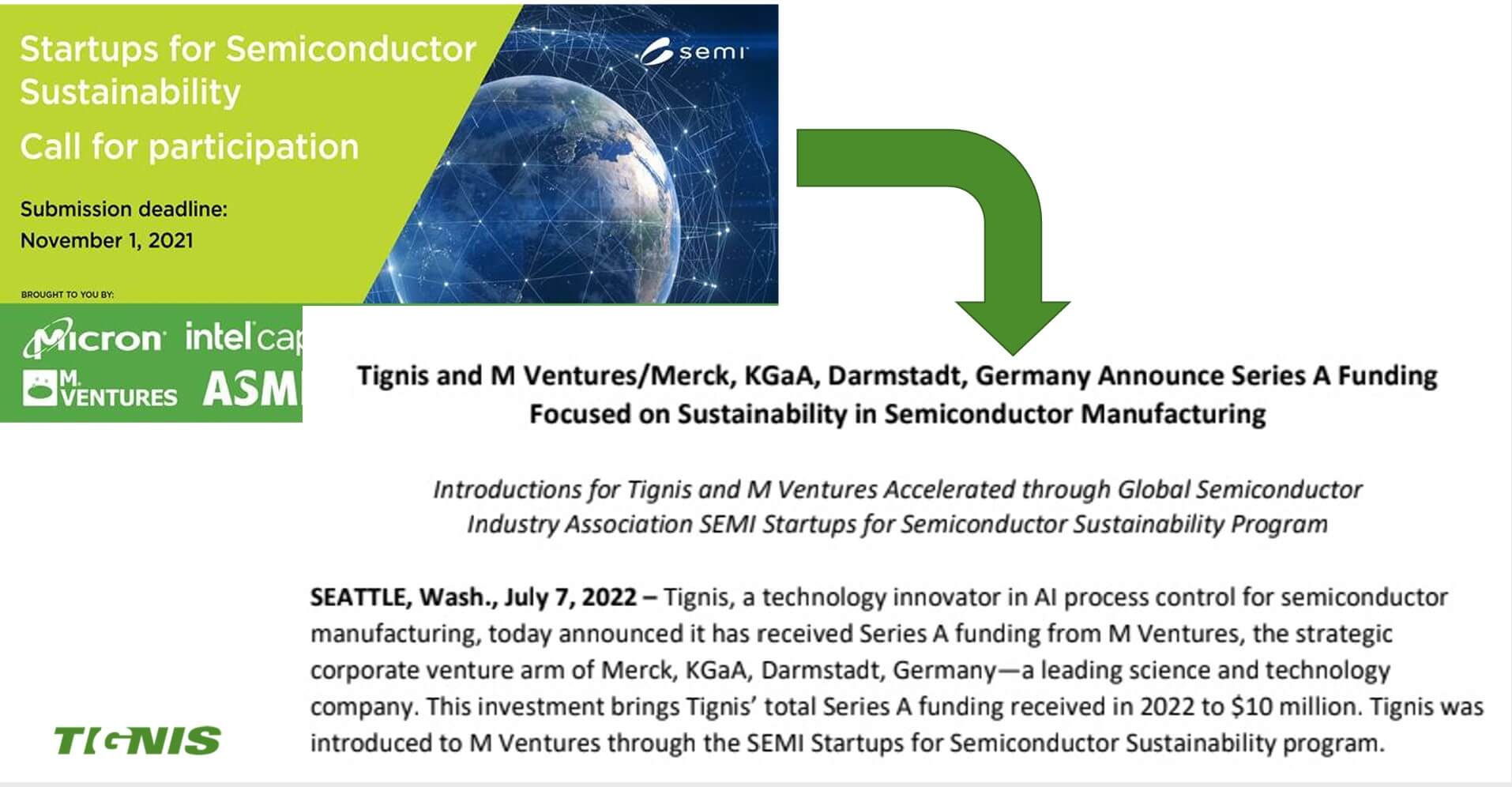

What the venture arms discovered was that it was difficult to get the sustainability startup companies’ attention. This was due to the nicheness of the semiconductor industry. In the start-up’s view, the opportunity was too small, or the specifications were too demanding. Thus, some of the venture arms banded together and created a sustainability startup event/contest where companies could enter the contest and if they were selected, they would receive some investment, but also get paired with one or more of the VCs to help them define their company roadmap into the semiconductor industry.

58 companies were whittled down to nine. Several of these companies gave presentations at SEMICON West in the sustainability startup showcase sponsored by M Ventures. Aqua Membranes, Atonarp, FTD solutions, Infinite Cooling, Infinitum Electric, Membrion, NuMat Technologies, Purity ReSource, Tignis all presented. Verdigris, who was a finalist, did not present.

If It’s Not Broken, Don’t Fix It

This was a phrase I heard occasionally in my career as a fab process and facilities engineer. In some cases, that mantra still holds true in the fab. Once the process or system is set up, it doesn’t change. If the need for a different filter, chemical, or part is required, then it takes a great deal of qualification to get the process to change.

Andy Byrne of Micron called it “the fear of perturbing the billions of dollars facility.” One of the key challenges the startup companies and the VCs face is getting the ear of the engineering and facility manager to get the proof-of-concept (POC) tests completed. The VC panel felt that being able to fast-track POC and show a company how their product could be used in the semiconductor environment would be valuable to the startup.

Startup Contest Synopsis

The three areas of focus for the startup contest were energy efficiency, water, and material usage. Here is a very quick synopsis of the talks.

Infinitum Electric

In the energy space, Infinitum Electric presented a new motor technology that eliminates the copper windings to eliminate weight, iron, and most of the copper. Motors consume 50% of the world’s electricity. The proposal is that the motor uses significantly less material, has much higher efficiency, and uses less electricity. The motor runs with less noise and vibration. If you have ever been in a sub-fab you know how noisy it is.

Verdigris

I was disappointed not to see Verdigris, as I have been following them since my days of tracking energy consumption in buildings. With Verdigris, you have the ability to monitor your energy usage by circuit breaker so you can track energy use and determine if energy is being wasted.

Aqua Membranes

Water consumption and recycling are a big concern for fabs’ generating high-purity water for processing, and then reclaiming the water from the process.

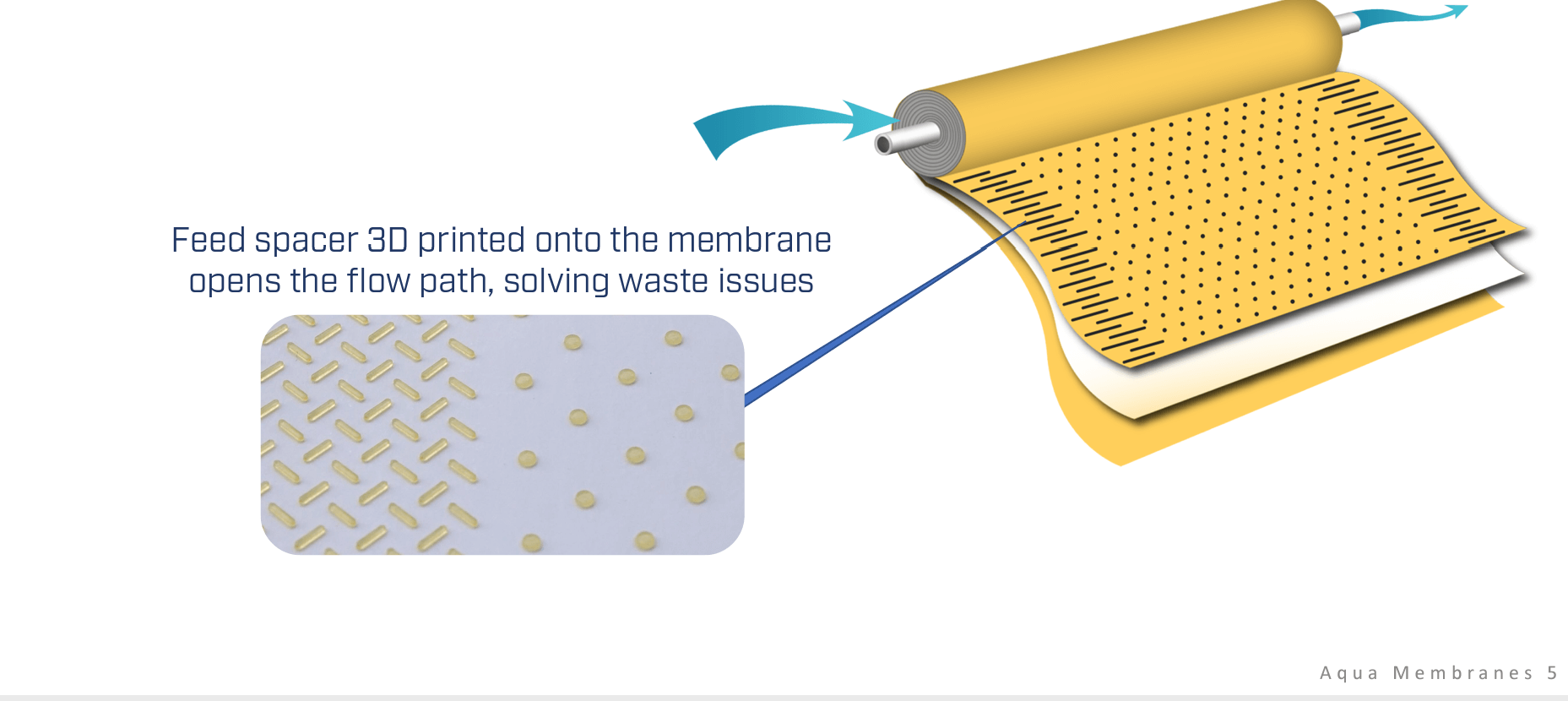

To create high-purity water, most fabs use a reverse osmosis process (RO). Very little has changed in the RO process over the years. Aqua Membranes has developed a printed spacer mesh that creates a more open flow path. This saves energy and increases the capacity by 40%. Aqua Membranes says it has performed several successful POCs and will be able to support larger orders by the end of 2022.

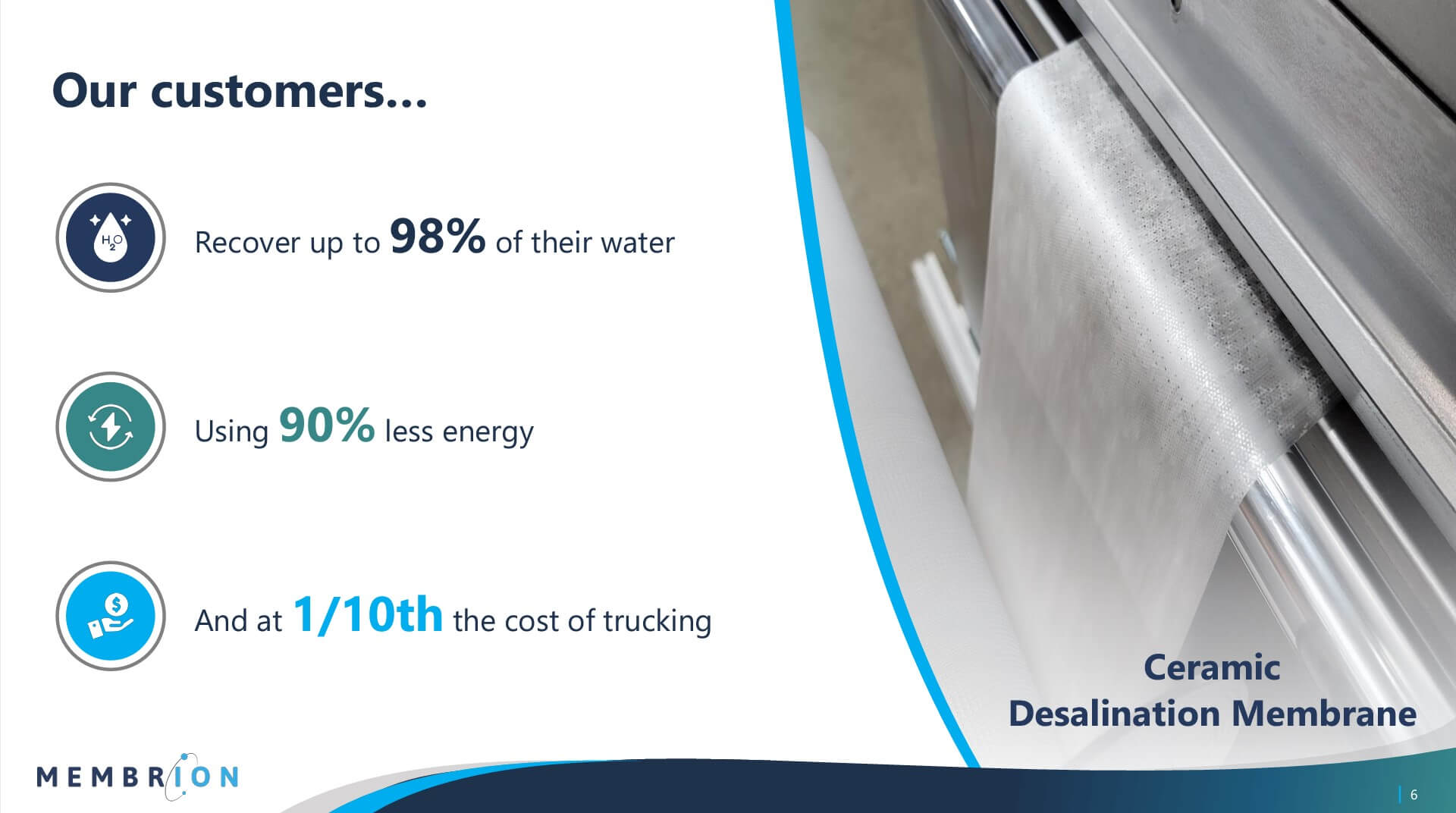

Membrion

On the topic of waste recovery, Membrion has developed a ceramic membrane that can be used in harsh environments. This would enable fabs to potentially filter out the hazardous chemicals and recover and recycle more of their water. Membrion has multiple POCs completed in multiple industries. This is a good example of a startup that may not have targeted the semiconductor space, succeeding, and helping companies achieve their sustainability goals.

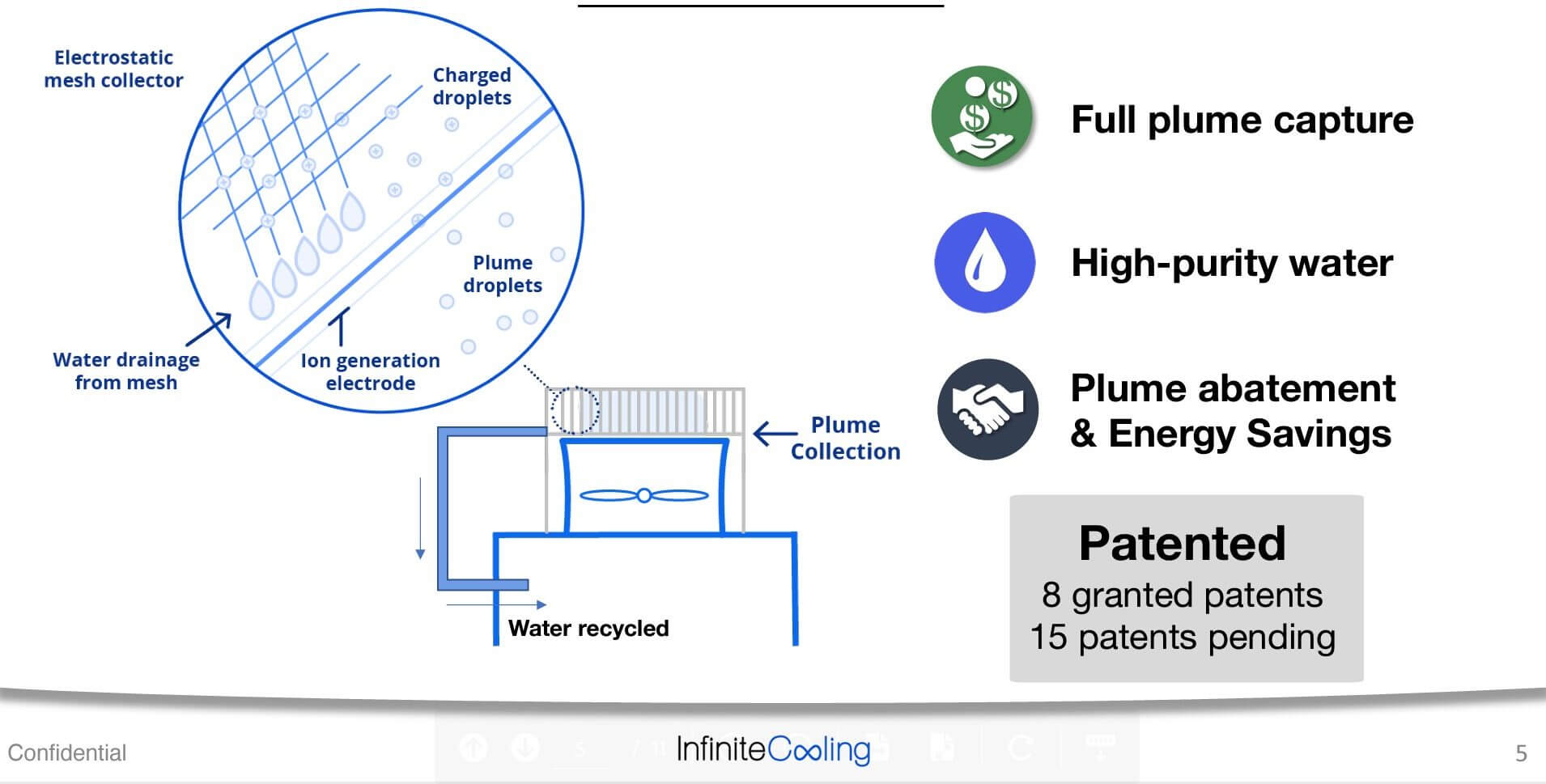

Infinite Cooling

Infinite Cooling has developed an electrostatic mesh that recovers some of the water used in evaporative cooling and then returns it to the system. The system captures the water that forms the plum and can save dollars and reduce water consumption, and potentially power. There was no data presented on the potential savings, but the company has nine projects in place, so it will be good to hear some results at a later presentation. This is one of the good examples of a sustainability solution that can address multiple industries.

Purity Resource

On the materials side of the presentations, Purity Resource was looking at how to perform onsite recovery and reprocessing of the chemicals, using an onsite distillation column. It will be interesting to see how it plays out, as it appears to add significant complexity to the waste recovery process, and the need to prove chemical purity levels will be a challenge.

FTD

Software is also part of the sustainability solution.

FTD discussed how to leverage its software to help industrial sites run smoother; potentially developing digital twins to help fabs run at optimal performance. The company is considering starting with the water operations and then moving to other parts of the fab. Digital twins have been gaining popularity in multiple industries. The Semiconductor has had a history of the golden tool, which all other processes must match. It will be interesting to see what the digitization of the fab, equipment, and processes result in. Hopefully more consistency, and lower costs.

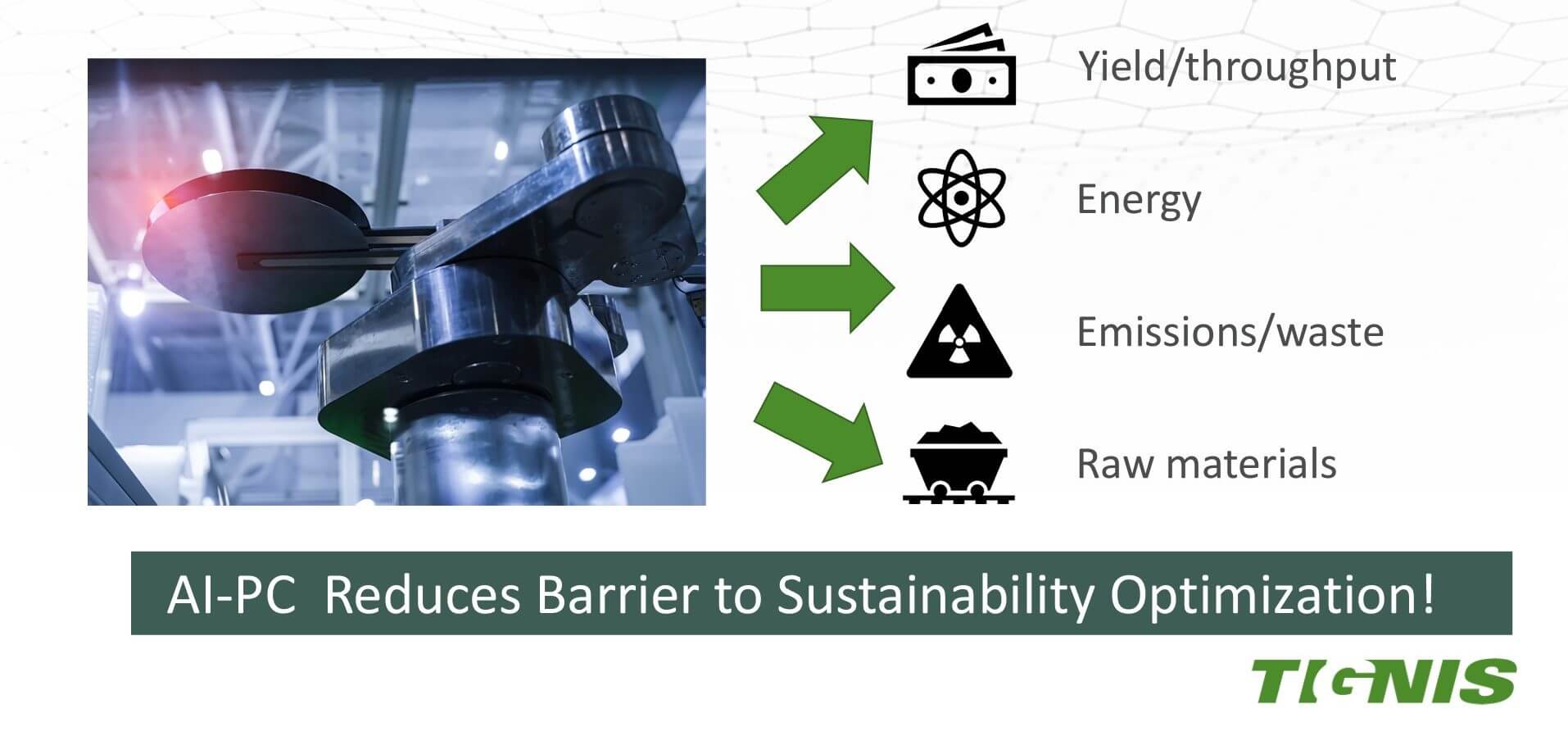

Tignis

Tignis is implementing AI software that will diagnose and monitor fab processes to help improve sustainability. Implementing AI process control to improve yield and quality, it can also be used to tune the process to sustainability at no extra cost. Thus, sustainability can be achieved at potentially a low cost. They have two products available on the market to enable process engineers.

AI and digital twins have been gaining popularity in the semiconductor manufacturing space. Lam Research has been promoting Semiverse, where you can develop processes using a virtual fab and machine learning (ML). This can hopefully reduce development time and potentially save chemical and energy costs when developing new processes.

For the first go-around, the sustainability startups appear to be off to a good start. As pointed out above, many of these startups have funding and are deeply involved in either proof of concept or in the process of scaling up. Some of the startups mentioned how valuable the program had been for them, as they receive exposure to multiple VC arms in the industry that the startups would potentially not have had access to if not for the SEMI sustainability startup program.

SEMI and the industry VC arms are continuing the program in 2022 and submissions are due on November 1, 2022.

It has been said multiple times in presentations that sustainability will need to be a cross-industry collaborative effort. This is a great example of how the industry has come together to promote and develop sustainability projects that will help us all get closer to net zero. ~ DF