In March, I was invited to be part of the panel; at SEMI’s Silicon Valley Virtual Forum: “Environmental Sustainability – Semiconductor Industry Challenges”. SEMI is working on taking a greater role for its members in helping to define what sustainability means, and how to address it. In most cases, both semiconductor and semiconductor manufacturing companies are still struggling to define and capture their Green House Gas (GHG) emissions. According to James Amano of SEMI member companies have requested that SEMI help define a common way to move forward on the sustainability front.

The panel included:

- Cheryl Knepfler, Vice President Marketing, Ultra Clean Technology and SEMI Silicon Valley Chapter Committee Chair

- James Amano, Senior Director, Standards, EHS, and Sustainability, SEMI

- Dean Freeman, Chief Analyst, Freeman Technology and Market Advisors

- Andrew Byrnes, Venture Capital, AI, Micron Technology

- Chris Librie, Director, ESG, Applied Materials

- Bill Seymour, Vice President and Co-Chair of Corporate Social Responsibility (CSR) Council, Entegris

- Mark Patel, Senior Partner & Sebastian Goeke, Associate Partner, McKinsey & Company

Cheryl Knepfler, moderated the session, and SEMI’s James Amano kicked things off by outlining SEMI’s efforts in the space and defining SEMI’s sustainability initiative. SEMI has been busy working and defining how to help member companies respond to ESG. For sustainability, they have formed an advisory council of companies that are key players in the SEMI space and that in most cases have stated their sustainability goals.

SEMI has also formed working groups to focus on an impressive list of ESG topics as well as help in workforce development. The good news is that this sets a line in the sand for the industry to begin working towards ESG goals.

Evidence of some of the early work is the announcement in February of the Startups for Semiconductor Sustainability. This program creates financing for multiple startups that are working on innovative ideas to help with sustainability in the industry. I’m hoping that SEMI will continue to give updates as to how successful these startups are as their concepts move into full-blown operation.

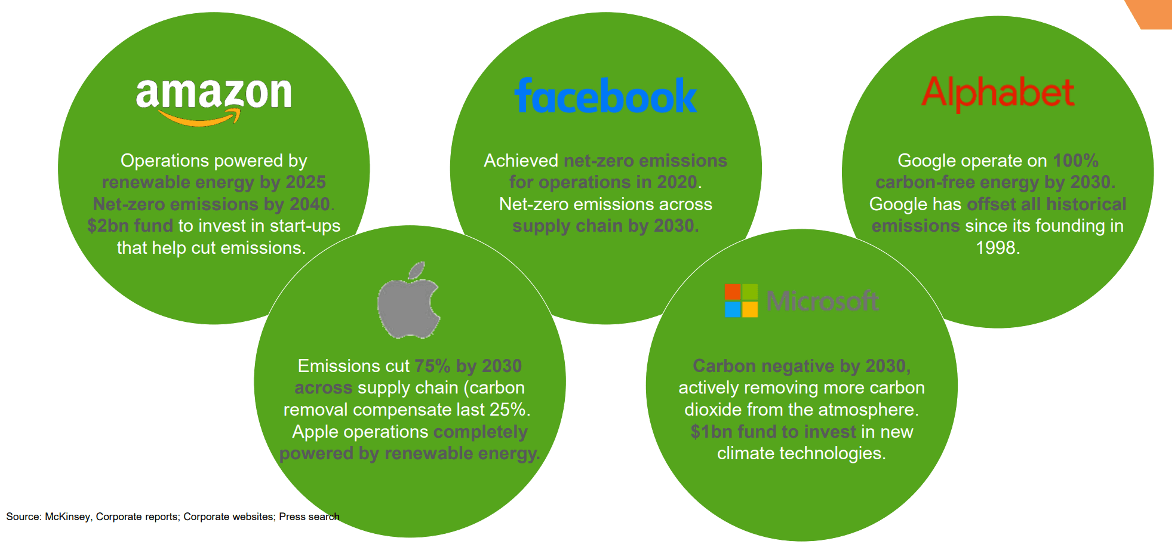

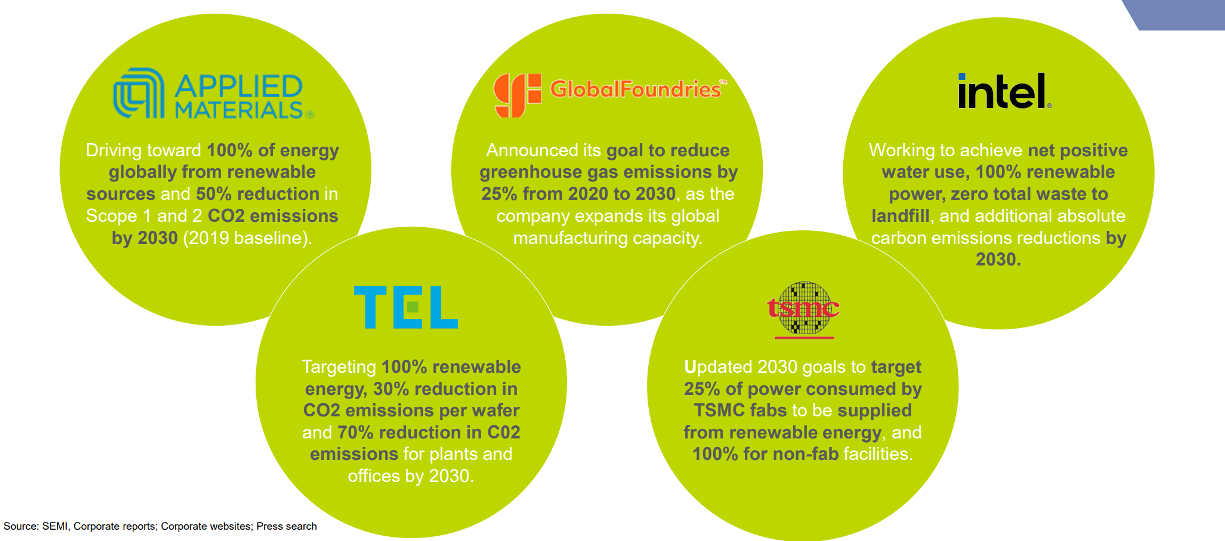

Amano also highlighted what companies’ goals and actions are in the sustainability space. The big players in technology all have challenging goals, and in some cases are at net-zero emissions. They have also stated that their supply chains need to get to net-zero, but as I pointed out in my presentation and last month’s blog, this is where the real challenges start. While renewables are growing rapidly, can they keep up with the demand of the entire industry going to net-zero by 2030? There is also the issue of carbon credits that in some cases are a significant portion of getting to zero.

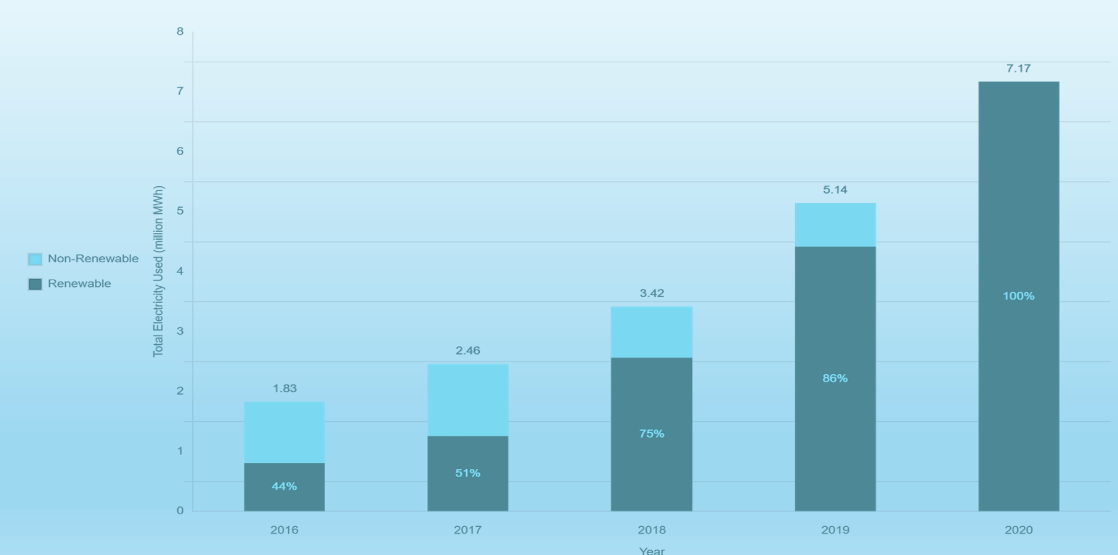

We should also be concerned about implementing renewables without conservation. Figure 1 shows that Meta’s energy consumption has been growing at 100% every 2 years. It is likely that other server companies have a similar energy pattern. Conservation also needs to be a big part of the getting to zero equation. Developing servers that use less energy, chips that use less power, and algorithms that are more efficient all need to be part of the conservation equation.

In addition to the above challenges, renewables have their own sustainability and supply chain issues. At the moment only about 10% of solar panels are recycled, and most of the blades for wind turbines end up in landfills. Thus, a better circular economy needs to be built around renewables for any company to declare success by using renewables to get to zero.

From a supply chain perspective, a significant number of solar panels, and most of the refined lithium used in the batteries for storage come through China. This will create challenges for renewables as the world ramps up demand for solar and wind power.

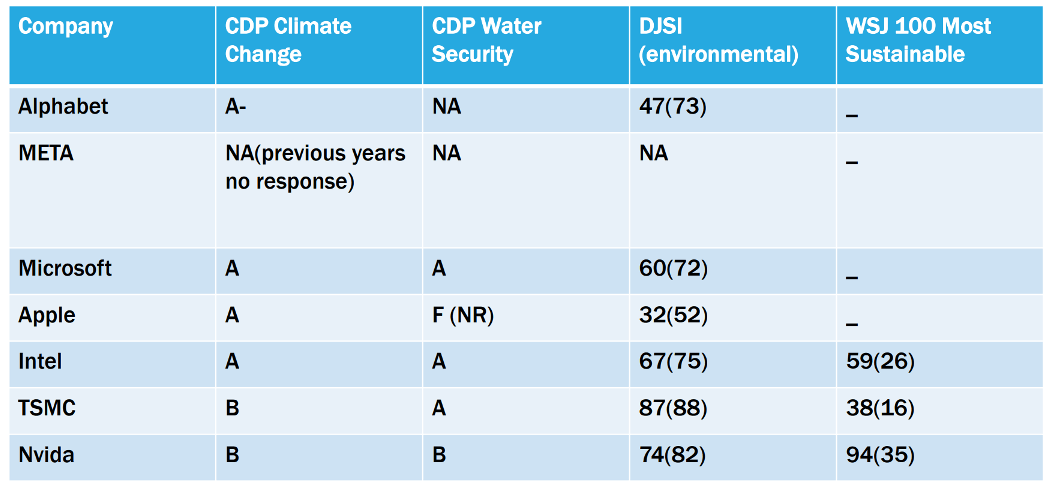

One last point on companies’ success in implementing sustainability programs can be seen in the reports or grading by three of the many organizations that evaluate sustainability programs. From the data in Figure 4, it can be seen that not all sustainability programs are judged equally, and not all companies that are promoting sustainability submit data. The fact that Meta claims to be 100% renewable, but has no scores should not be acceptable, nor the fact Apple and Alphabet are not reporting water scores. It will be interesting to see over time, as reporting methods become more standardized if scores between agencies will normalize.

Perhaps my favorite talk of the day was by Andrew Byrnes. Byrnes looked at the investment climate for sustainability in the Semiconductor industry. Byrnes pointed out that the semiconductor industry is viewed as a niche market and has high barriers to entry, which can make it challenging for a startup and VCs to recoup their investment. Byrnes also highlighted some of the challenges the semiconductor industry faces with becoming sustainable.

Figure 5 highlights the challenge of getting to zero for an Island such as Singapore or Taiwan. The small blue square in the upper left-hand corner shows the size of the Fab. The purple square shows the footprint needed for solar panels to support the fab. Wind would help reduce the solar footprint, but this diagram demonstrates one of the issues of getting to zero. And especially the challenges Taiwan and Singapore will face as they work to reduce their carbon footprint.

Byrne went on to highlight the process used for the startups for semiconductor sustainability. Byrne also highlighted one of the topics I have been discussing over the past year. End-to-end IC design for sustainability. Moving in this direction will be necessary to achieve industry goals in the future and reduce the amount of computing power needed in the future.

Chris Libre shared Applied Materials goals and progress on the sustainability front (Figure 6). My key takeaway here is that Applied Materials is actively working with suppliers to look at how to reduce the energy generated in the fab during the manufacturing of the chips. I’ve published before on the work going on in the sub-fab that reduces energy consumption by idling the sub-fab equipment. Rolling this out industry-wide at all technology levels would help fabs see an immediate reduction in carbon emissions.

Applied is also looking at reducing energy, chemical consumption, and the footprint of process equipment. Hopefully, some of these energy reduction solutions will be able to go industry-wide and not just be relegated to Applied Materials tools.

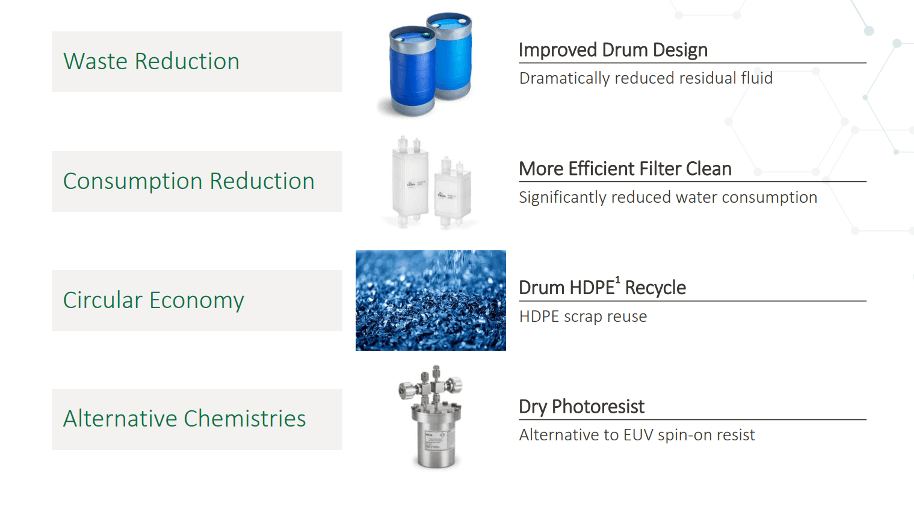

Bill Seymour of Entegris shared his company’s journey on ESG. Entegris published its first CSR report in October of 2021, after having set goals in August of 2020. If the presentation Entegris appears to be moving fairly aggressively to achieve sustainability goals. Seymore laid out several of the projects Entegris is working on to help the industry be more sustainable, looking at how to reduce chemical waste and better recycling of containers, as well as alternatives to spin on photoresist.

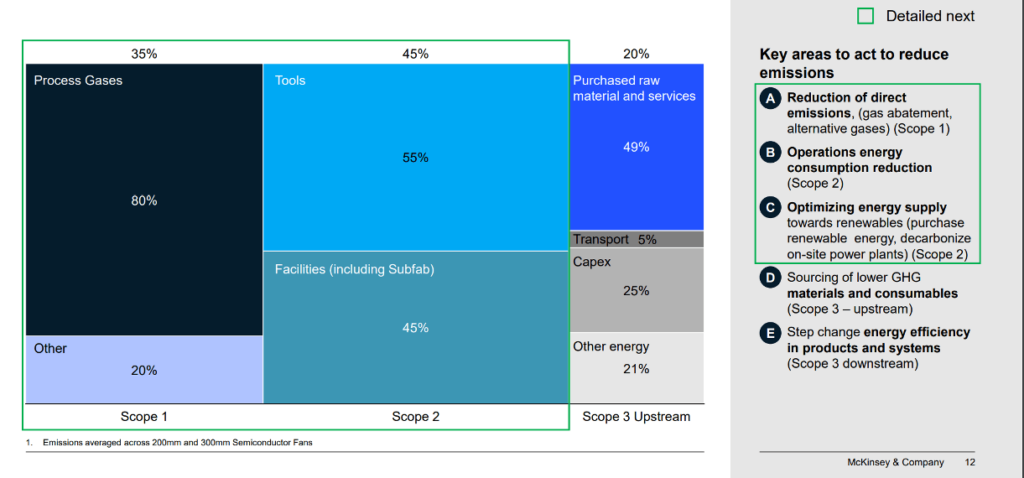

Mark Patel and Sebastian Goeke closed out the seminar with work McKinsey has been performing in the sustainability area. They pointed out that reduction across a fab will be challenging and it is important to look at the energy expended versus the carbon produced in trying to minimize the carbon footprint.

Scope 1 emissions make up 35% of a Fabs carbon footprint with 80% of that being process gasses. This would suggest that abatement as well as working to reduce the amount of process gases emitted would be beneficial. However, there has been some discussion about the impact of 100% abatement vs. 95% abatement. Process gas recovery might be another solution, but again what is the GHG impact of capture vs. abatement. 45% of a fab’s emissions is the energy used by tools and the facilities, which also include the sub-fab. Thus, the programs, Applied Materials is working on will have an immediate impact on emission reduction, once they are implemented.

Figure 8: Emissions of typical fab mostly from process gasses and electricity consumption (Source Mckinsey)

My overall takeaway is that we are still very early in the process of understanding and implementing programs that will focus on reducing GHG emissions. My perspective is also that we can not just use renewables as the solution. There has to be a focus on the reduction of energy used both in computing and in creating the chips for computing. There also needs to be a bigger focus on the business models of the electronic equipment suppliers. Replacing a mobile phone, watch, or tablet on a yearly basis needs to be reviewed. Samsung has recently launched a significant recycling program that has received EPA awards.

I am pleased to see that SEMI and many players in the industry are working hard to achieve ESG goals. I’m looking forward to seeing what happens over the next ten years and how successful we will be in reaching the goals for zero.