Reshoring

With the ongoing deluge of reshoring activity in the US, it is good to see others pointing out that just manufacturing chips is not what we are after. As IFTLE has steadfastly stated, we need the complete infrastructure moved back onshore and that absolutely includes the new golden child: microelectronics “packaging”.

For those who haven’t seen it, read “Reshoring Chip Industry Risks Failure with Just More Fabs” in EE Times.

IFTLE absolutely supports the statement by Matt Kelly of IPC, who is quoted as stating “There’s a lot of concern about just propping up the industry artificially and when the incentives go away, the whole game plan goes away. Unfortunately, that’s — at least from my perspective — where we are right now.”

Hopefully, we all understand that these monies are not being spent to assure millennials have the latest chips for their gaming devices or baby boomers have the latest smartphones, but primarily so that the DoD can have access to the latest technologies for our country’s defense.

Many companies have, in the past, shunned government or military work because of the large number of low-volume parts required. IFTLE certainly hopes that US companies can see past the dollar signs, and that all the fabless US companies can understand the pickle they will be in if they are ever cut off from their current overseas suppliers. It is certainly in their best financial interest to have competent, state-of-the-art (SOTA) production (chips, advanced packaging, and assembly) available in the USA and certainly in the best interest of all of us for the DoD to have these technologies available for our defense.

Hopefully, we can all agree 100% on the fact that we don’t want to be manufacturing chips in the US and then shipping them off to Asia to be tested, packaged, and assembled. That would defeat the purpose of manufacturing them over here in the first place. So, while IPC (in the above-mentioned article) is naturally focused on the complete lack of advanced substrate production in the US, IFTLE would state more broadly that we need to reshore the complete packaging infrastructure.

ALL or NOTHING is how we see it.

The current reshoring legislation like the CHIPS Act actually calls out packaging and testing, but there are questions about how the purported $52B will be allocated. In the EE Times article, the author reports from “un-named industry lobbying sources” that “…about $2.5B of the $52B planned for subsidies will probably go to advanced packaging…” If that is true, once again it appears that the front end, who has always lived “high off the hog” will get the lion’s share of what’s available. That may have made sense in the 1990s but this is now the 2020s and the back end is more important than ever. Hopefully, those who allocate the monies will come to understand that. IFTLE will certainly do its part to try to make that happen.

Skywater and Reshoring

One of the companies positioning itself to supply SOTA packaging for this reshoring effort is Skywater.

In their recent IEEE EPS webinar Chuck Woychik, senior director of advanced packaging platforms addressed “On-shoring the Next Generation of Advanced Packaging” so let’s take a look at what he said.

Recall that Skywater evolved from the former Cypress Semiconductor Minnesota fab. In 2017 they achieved DMEA trusted accreditation by the U.S. Government. In IFTLE 481, “ A Bridge to Somewhere” we discussed how they have taken over the operation of the “Bridg” facility near Orlando FLA (now called SWFL by Skywater).

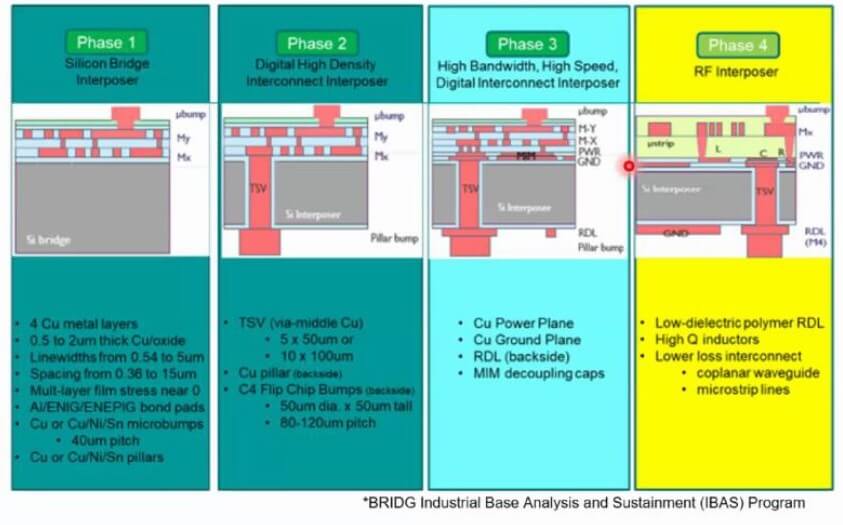

They see this as their base for future packaging operations. They are selling themselves as a technology foundry capable of high customization and variable volumes. Right now, they are looking at 200mm production.

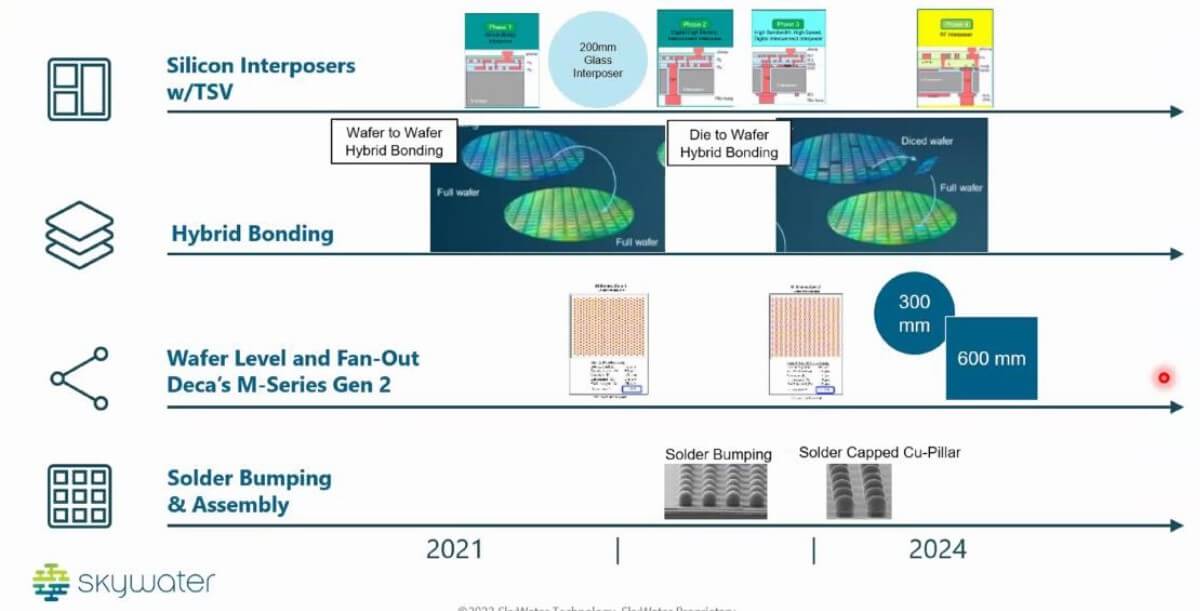

Most important are the technologies that they are focused on. IFTLE would highlight this for anyone wanting to claim they are in the high-end packaging business. Shown below is the minimum of what you need to be offering.

As we have discussed previously [IFTLE 481] their silicon interposer and TSV technologies come via Eric Beyne and IMEC.

SkyWater has indicated that it intends to license hybrid bonding technology as opposed to developing it internally. IFTLE expects this means Skywater will be working with Xperi to bring this capability in-house.

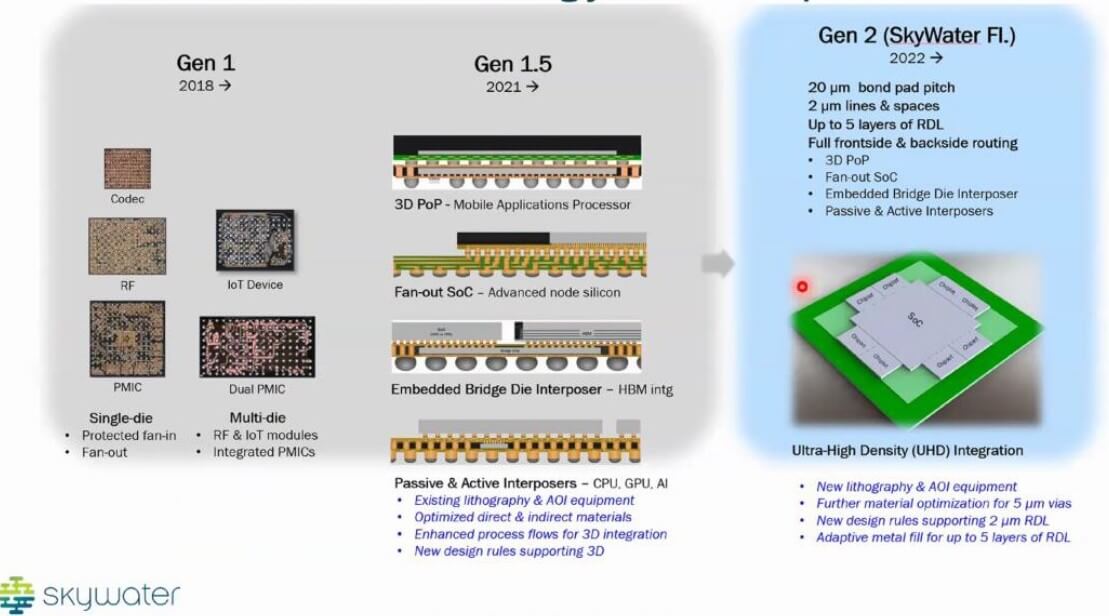

We know that the company has licensed Deca’s M-Series and will be bringing up their Gen 2 fan-out packaging technology in 200mm format in Florida. (Figure 3)

As we all know solder bumping and copper pillar bumping have become basic packaging technology and unfortunately, there is very little capable, experienced merchant capacity in the US today.

FCI (previously FCT), which started it all in the late 1990s in Arizona is currently owned by Huitian Technology Group in China, and Micross in RTP NC has a limited 200mm capacity. Neither of them has 300mm capacity.

Skywater sources indicate that they are going to work with an external provider for the foreseeable future (IFTLE guesses that this would be Micross since there are no other obvious choices) and they are not currently engaged in bringing that in-house. For those who haven’t heard, Skywater recently hired Alan Huffman away from Micross. Alan ran the bump line at Micross and I’m sure will have plenty to say about what Skywater does in this important advanced packaging area.

So the bottom line here is that IFTLE gives the roadmap and their proposed onshore technology offerings an A+. Now let’s see if over the next few years if they can actually deliver all this advanced technology.

For all the latest in Advanced Packaging stay linked to IFTLE……………….