Vantex™ redefines high aspect ratio etching with new innovations in technology and Equipment Intelligence® enabling chipmakers to progress 3D NAND and DRAM roadmaps

FREMONT, Calif., Jan. 27, 2021 (GLOBE NEWSWIRE) – Lam Research Corp. (Nasdaq: LRCX) today announced Vantex™, the latest in dielectric etch technology designed specifically for Sense.i™, the most intelligent etch platform available today. Built on a legacy of etch leadership, this pioneering design delivers higher performance and greater extendibility for current and future generation NAND and DRAM memory devices.

Chipmakers building 3D memory devices used in applications such as smartphones, graphics cards, and solid-state storage drives continually strive to reduce their cost per bit from node to node by increasing device dimensions vertically and reducing critical dimensions (CD) laterally. This is driving etch aspect ratios in 3D NAND and DRAM to new levels.

Vantex’s new chamber design enables the use of higher than previously available radio frequency (RF) power levels in order to etch high aspect ratio features at high throughput and achieve cost scaling. The increased power is coupled with advancements in RF pulsing technology to deliver the tight CD control required to improve device performance.

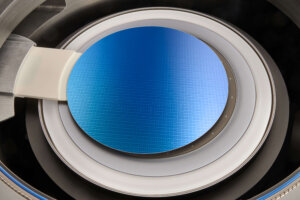

The 3D NAND device roadmap requires etching to achieve greater depths with every new generation, driving a need for improved etch profile uniformity. The Vantex technology controls the vertical angle of the etch to meet the tighter placement requirements of these 3D device features and achieve high yield across the entire 300mm wafer.

“With more than a decade of industry leadership in high aspect ratio etch, our unique learning enabled the Vantex chamber design from the ground up to offer scalability and innovation for many nodes to come,” said Vahid Vahedi, senior vice president and general manager of the Etch product group at Lam Research. “Vantex redefines performance and productivity benchmarks, driving our customers to leverage this groundbreaking etch technology.”

Lam’s Sense.i etch platform with Equipment Intelligence® includes capabilities for collecting data from hundreds of sensors monitoring system and process performance. The Vantex chamber leverages the high bandwidth communication in the Sense.i system to collect more data per wafer than any other tool on the market – with the ability to utilize data much more efficiently in order to improve both on-wafer and wafer-to-wafer performance.

Vantex on the Sense.i platform continues to ship to Lam’s leading memory customers for qualification, with repeat orders to ramp in high volume production in 2021.