Frontier Semiconductor has recently introduced Virtual Interface Technology (VITTM) for TSV Inspection.

In the realm of 2.5D/3D packaging, a high throughput/production ready metrology tool with a single high-performance sensor that addresses multiple measurement needs throughout the process flow, from FEOL to BEOL, can be very valuable in terms of yield improvement, cost of ownership reduction and tools utilization. A metrology tool developed at FSM based on Virtual Interface Technology (VITTM) has demonstrated its ability to be useful in the front end where the measurement features are only a few μm thick/deep and in the backend where the measurement range spans out to be several millimeters. Thus this technology can provide tool to tool compatibility at different measurement infliction points along a process line.

In the realm of 2.5D/3D packaging, a high throughput/production ready metrology tool with a single high-performance sensor that addresses multiple measurement needs throughout the process flow, from FEOL to BEOL, can be very valuable in terms of yield improvement, cost of ownership reduction and tools utilization. A metrology tool developed at FSM based on Virtual Interface Technology (VITTM) has demonstrated its ability to be useful in the front end where the measurement features are only a few μm thick/deep and in the backend where the measurement range spans out to be several millimeters. Thus this technology can provide tool to tool compatibility at different measurement infliction points along a process line.

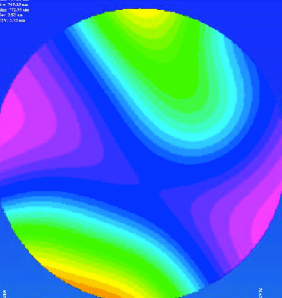

VITTM is a Fourier domain technique that utilizes temporal phase shear of the measurement beam. The unique configuration of the sensor enables measurement of wafer and bonded stack thicknesses ranging from a few microns to millimeters with measurement repeatability ~ nm and resolution of approximately 0.1% of nominal thickness or depth. In this paper, data are presented on high aspect ratio via measurements (depth, top critical dimension, bottom critical dimension, via bottom profile and side wall angle), data on debris inspection at via bottom, bonded wafer stack thickness, and Cu bump measurements. A complimentary tool developed at Frontier Semicondutor is a high resolution μRaman spectrometer to measure stress-change in Si lattice induced by TSV processes. These measurements are important to determine Keep-Out-Zone in the areas where devices are built so that the engineered gate strain is not altered by TSV processing induced strain. Applications include via post-etch; via post fill, and bottom Cu nail stress measurements. The capabilities of and measurement results from both tools are discussed.

Download the complete white paper, An Optical Technology for TSV Inspection.