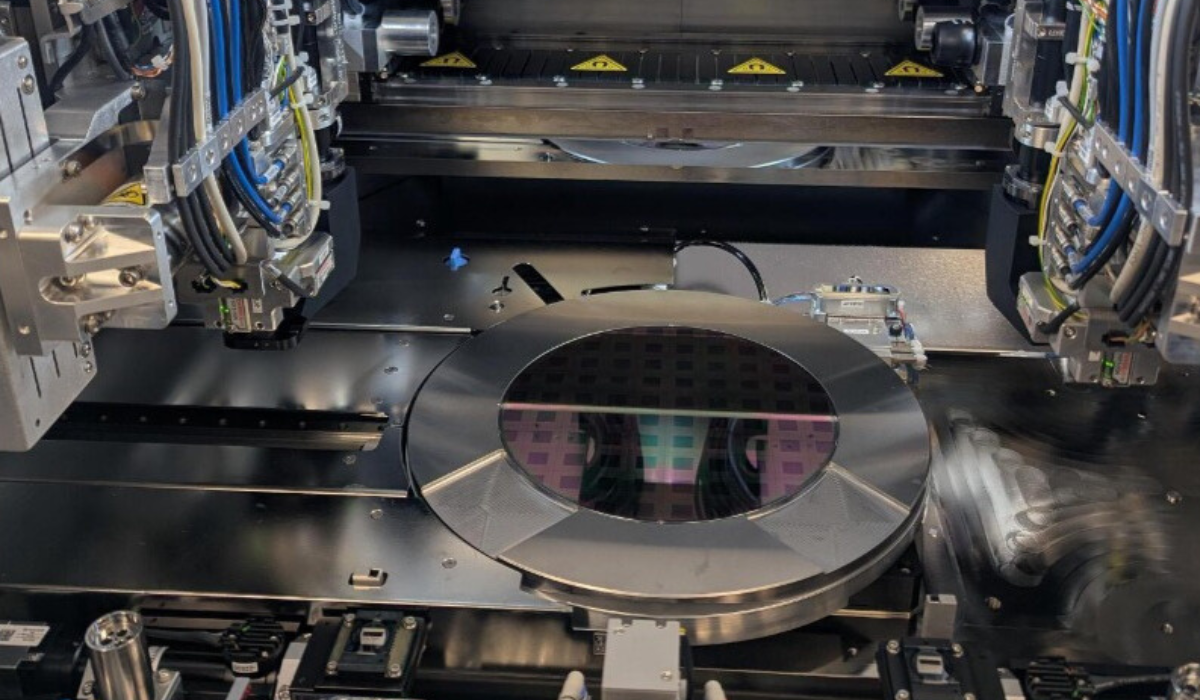

The company’s recently delivered Besi Datacon 8800 CHAMEOultra plus system is the world’s first operational advanced bonder of its kind to enter production

NHanced Semiconductors, the first U.S.-based pure-play advanced packaging foundry, uniquely supports mixed-material hybrid bonding with either copper or nickel bonds. Their new Besi bonding system further expands its advanced packaging yield and throughput.

NHanced announced earlier this year that it had taken delivery of the first BE Semiconductor Industries (Besi) Datacon 8800 CHAMEO hybrid bonding system at the company’s advanced packaging facility in Morrisville, NC. The new bonding system represents the latest in ongoing investments by NHanced to expand its advanced packaging production. Among its suite of technologies, NHanced delivers the Direct Bond Interconnect (DBI®) room temperature hybrid bonding process that joins wafers, dies, and chiplets with both dielectric covalent bonds and metal-to-metal fusion bonds. DBI® produces unmatched fine-grained interconnects for 2.5D and 3D assemblies. NHanced has uniquely expanded its DBI® process capabilities to include heterogeneous integration of GaN, GaAs, InP, LiNbO3, glass, and diamond substrates, and is the only company offering both copper and nickel for bonding.

“NHanced has already successfully delivered more hybrid bonding products than anyone else in the industry. The new Besi system significantly expands the hybrid bonding capabilities of our Morrisville, NC facility,” said NHanced president Robert Patti.

NHanced is the first pure-play advanced packaging foundry to operate this Besi hybrid bonding platform – a key enabler for ultra-precise die-to-wafer alignment of 200 nm with interconnect pitches down to 1 µm. The system can process up to 2,000 dies per hour, resulting in ~10x faster throughput with increased yields and superior warpage control.

NHanced has pioneered a paradigm shift in semiconductor manufacturing that it calls “Foundry 2.0” – applying semiconductor foundry processes and advanced packaging and assembly technologies to dies and chiplets sourced from traditional foundries. The results are customized 3DIC and 2.5D advanced packaging and interposer assemblies. NHanced is the only U.S.-based foundry that can support this manufacturing model.