For decades, chemical mechanical planarization (CMP) has been one of the enabling technologies of semiconductor manufacturing. Without ultra-flat and uniform surfaces, today’s microprocessors, memories, and high-density interconnects would not exist. But as the electronics industry pushes beyond wafer-centric paradigms toward panel-level packaging, advanced substrates, and heterogeneous integration, conventional CMP concepts are no longer sufficient.

The Shift from Wafer to Panel

The transition from wafers to panels is driven by several converging market forces:

- Cost and yield pressures require larger formats and panel-level packaging.

- Artificial intelligence and high-performance computing demand unprecedented integration density.

- Advanced substrates such as glass cores, SLPs, and TGV-based interposers are gaining traction in packaging roadmaps.

Traditional CMP systems, optimized for 300 mm wafers or at most ~400 x 400 mm substrates, cannot address these requirements. Next-generation substrates are larger, thinner, often fragile or flexible, and present significant topography from multilayer build-ups. They also require precise endpoint detection across diverse material combinations, all at industrial throughput.

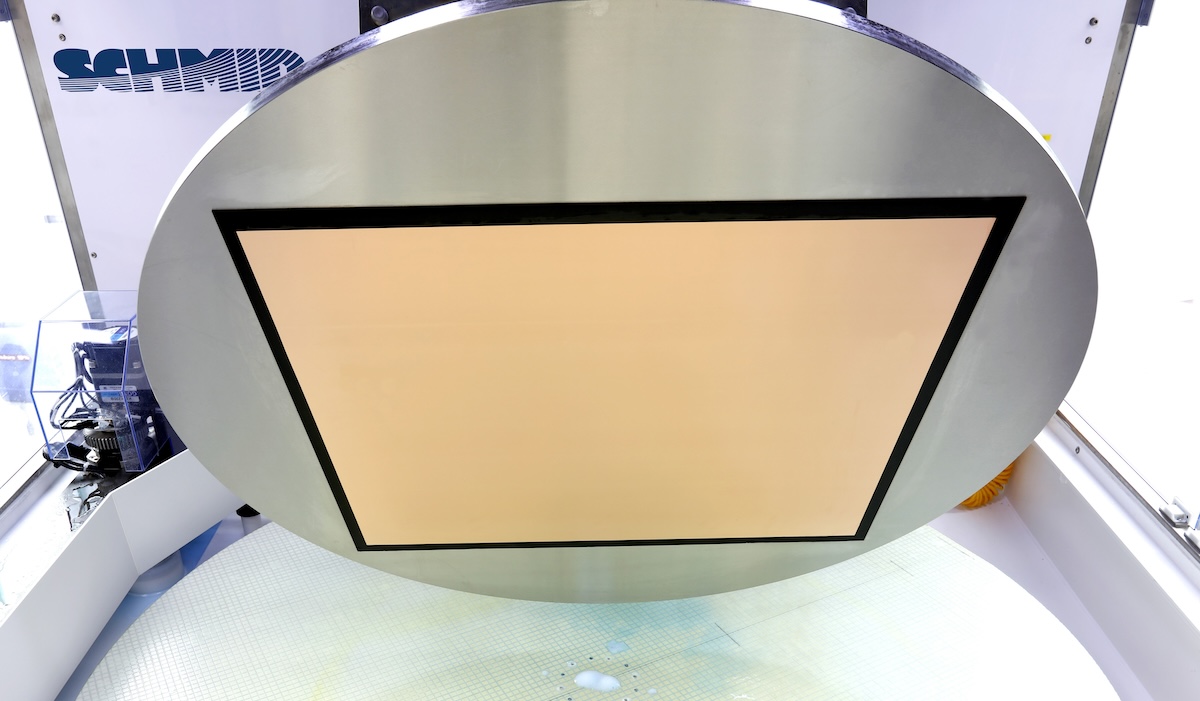

This is the environment for which the InfinityLine L+ was conceived.

Designed for large rectangular substrates up to 24.5” x 24.5”, the equipment delivers industry-leading flatness, reproducible process stability, and high throughput, making it a critical enabler for sub-5 µm structures in volume manufacturing.

A Purpose-Built CMP Architecture

At the heart of the InfinityLine L+ is a new slurry delivery principle. Instead of applying slurry externally from above, SCHMID’s design applies it centrally through the platen and distributes it uniformly across the entire surface. This ensures consistent removal rates while reducing slurry consumption, one of the biggest cost factors in CMP.

Fragile substrates are protected by:

- Configurable support materials

- Dedicated clamping devices tailored to product specifics

- Adaptive kinematics with scalable platen dimensions and workpiece holders

Together, these innovations make the InfinityLine L+ the first CMP system capable of handling both large panels and delicate substrates with equal reliability.

Process Stability and Control

Process risks such as fracture, uneven removal, or dishing have historically limited CMP adoption in large-format substrate processing. The InfinityLine L+ mitigates these through:

- The “Oscar” principle for uniform slurry application and reduced consumption

- Active platen cooling to ensure thermal stability

- Variable pressure control, adaptable for different geometries and materials

- Vacuum clamping with in-situ pressure monitoring for selective influence

- Real-time endpoint detection and live monitoring of all process parameters

The result: maximum flatness, minimal dishing, and reliable reproducibility, even across challenging material stacks.

Compact, Modular, and Automation-Ready

One of the strongest advantages of the InfinityLine L+ is its compact machine design, which combines flexibility with seamless fab integration. The system is fully automatable, enabling high-volume throughput without increasing footprint.

For maximum productivity, the InfinityLine L+ can be clustered into multi-system configurations of up to four units. Substrate handling is fully automated, with FOUP-based delivery to minimize contamination and external influences. Even double-sided processing is performed without losing substrate orientation.

Maintenance and consumable replacement are streamlined thanks to the equipment’s modular design. Pads, slurry, and backing films can be changed quickly, minimizing downtime and lowering cost of ownership.

For post-CMP cleaning, SCHMID offers the InfinityLine H+ inline cleaning system, fully integrated into EFEM automation. An integrated substrate buffer ensures uninterrupted production, even during service intervals.

Unlocking New Applications

The InfinityLine L+ is not just an incremental improvement, it is a platform technology. By extending CMP principles to large-format rectangular substrates, it enables entirely new application spaces:

- High-end substrate manufacturing for AI and HPC systems

- Foundries and OSATs integrating panel-level packaging into Advanced Packaging flows

- Glass-core and substrate manufacturers developing next-generation interposers

- Research institutes and universities pushing the boundaries of new materials and integration concepts

For each of these segments, the InfinityLine L+ delivers yield improvements, cost efficiency, and scalability, qualities that will define competitiveness in the coming decade.

Bridging Two Worlds

The InfinityLine L+ bridges two technological worlds. On the one hand, it draws on the state-of-the-art CMP expertise from semiconductor wafer processing, a field where nanometer precision has been perfected over decades, and adapts those principles to much larger, thinner, and more complex substrates.

By doing so, it offers the planarity, uniformity, and reproducibility that advanced electronics demand, but in formats aligned with the future of manufacturing.

Looking Ahead

The electronics industry is on the cusp of a new era. As heterogeneous integration becomes the standard architecture for AI, data centers, and next-generation consumer devices, substrates will play a decisive role in performance and cost. Flatness and uniformity at scale are no longer “nice-to-haves”, they are absolute prerequisites.

The SCHMID InfinityLine L+ delivers exactly this capability. With its unique architecture, robust process control, and automation readiness, it is not only solving today’s CMP challenges but also laying the foundation for tomorrow’s breakthroughs, from glass substrates to novel organic-inorganic hybrids.

For manufacturers, researchers, and technology leaders, the InfinityLine L+ represents more than a piece of equipment: it is a strategic enabler of the next generation of Advanced Packaging and substrate technologies.