This final post from my time at the 2015 MEMS Executive Congress addresses some random questions I had that were answered for me at this year’s event.

Can MEMS and sensors help keep the IoT safe?

Is there a difference between privacy and security? Many would say that there is; others are concerned about both. Those who grew up with the Internet aren’t concerned about their privacy, as they openly share their lives and lifestyle habits via social media apps, and search and shopping habits. In fact, many like that their devices are starting to anticipate their needs. However, everyone is concerned about protecting our critical data, and access to homes and autos.

Wouter Leibbrant, NXP, says security is about confidentiality and integrity. Whatever information is sent out is the same as what’s received in terms of authenticity and privacy. “I think I’m listening to one thing, and it could be something else. How do I know that all the data I’m producing is not falling into the wrong hands?” he said.

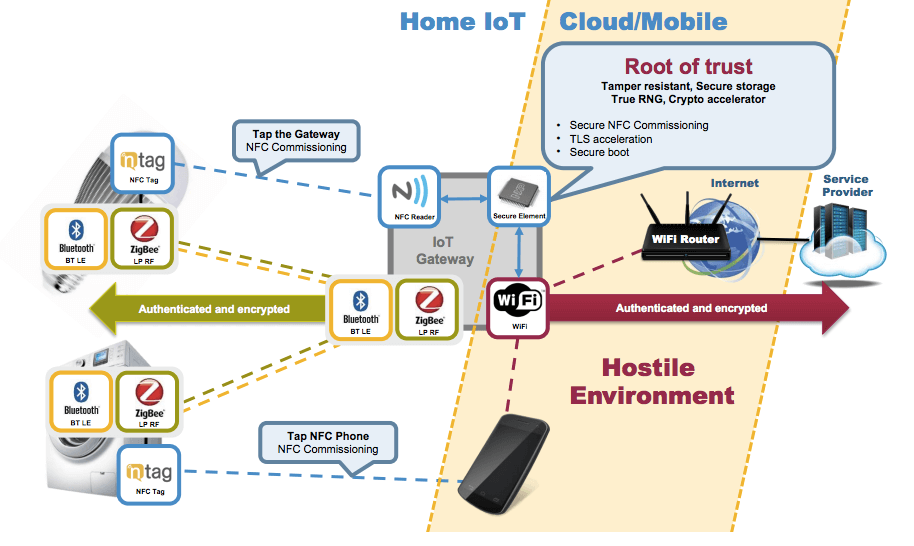

At NXP, where they are developing smart home systems, this is not something that is taken lightly. Leiibrant explained that NXP’s secure solution takes the perspective that everything outside my domain is hostile. Their “root of trust” devices allows them to build in authentication, encryption, and secure key exchange at strategic points in the system architecture.

“There are emerging domains for IoT, but this will only work if the connections that we make are more secure for this smarter world,” noted Lebbrant.

“Security is already solved on the IT side,” notes Maciej Kranz, Cisco, pointing to banks and the industrial architecture. “Many cyber attacks could have been prevented. We have a lot of tools and best practices and need to implement them.”

According to John Thompson, Dell Software, last year’s hack into Target’s point-of-sale system came through the company’s HVAC systems, as a result of everything being networked. “We’re going to have to firewall off things you never had to firewall off.”

Building security and encryption into the sensor device not only helps solve the security issue, the MEMS industry could also profit from it. “Security is by far the number one concern and the number one opportunity, otherwise customers will not adopt any of our systems,” says Todd Miller, GE Global Research.

Peter Hartwell, InvenSense, suggest that building an encryption engine into MEMS devices adds security and also value to the device; something the customer might be willing to pay more for.

What are the equipment guys going to do if paper is the next sensor substrate?

Seriously? A trillion sensors made of…paper? Although years away from being a viable substrate material for sensors, Alissa Fitzgerald, AM Fitzgerald and Associates, says we need to pay attention to its development, because it’s a viable solution for low-cost sensors. “Paper – as a silicon expert this opportunity both excites and terrifies me,” said Fitzgerald.

According to Fitzgerald, paper has its advantages: No cleanroom, a large-format substrate, high throughput… all this enables ultra low-cost sensors. Paper as a microfluidic electronic substrate will enable low-cost medical diagnostics, because afterwards the device can be destroyed.

I asked Dave Kirsch, EV Group, what this could mean for MEMS equipment manufacturers, who have made considerable investments developing process tools for silicon and compound semiconductor materials like SiGe and GaAs.

“Learning about material innovations help spur EVG’s innovation,” Kirsch said. “A lot of innovation moving forward will be materials oriented, and EVG is well prepared from the format perspective,” For example, to handle the potential of paper, they can leverage their experience with roll-to-roll materials used for lithography.

Kirsch was less concerned about paper replacing silicon in the future, and more concerned about addressing immediate needs in hardware adaptations now. He said the EVG is getting more queries about larger format wafers for MEMS. In particular, he sees incentive to move to 300mm as MEMS products become more mainstream.

Are 3D TSVS gaining traction in MEMS?

In a word, yes, and this involves bonding CMOS chips to a MEMS device, which Kirsch says requires modifying equipment and bond process to fit different applications. For example, helping customers bond under specific environmental conditions (vacuum, low temperature, low power). “We are working hard as we can to make our MEMS customer products more manufacturing-efficient and more performance efficient through our process, application and equipment expertise,” noted Kirsch.

Kirsch wasn’t the only one who referenced 3D TSVs as something starting to happen in MEMS integration. Frédéric Raynal, CTO of aveni, used part of his 10 minutes during the Elevator Speech session to explain how replacing wire bond interconnects between the MEMS and ASIC with TSVs enables smaller, high-density devices, which is needed to get high level sensor functionality. Also, building in the aforementioned security encryption into sensor devices will require higher aspect ratio (HAR) TSVs. According to Raynal, aveni’s nanometric film metallization processes can provide 100% step coverage on TSVs up to 40:1 aspect ratio. How do they do it? By growing nanometric films molecule by molecule on the surface of the TSV sidewall, rather than depositing them via physical vapor deposition (PVD).

Could we sleep at the wheel while driving cross-country in an autonomous vehicle?

This was the thought that entertained me during when Delphi Automotive’s Jeff Owens described his coast-to-coast automated drive in Delphi’s test vehicle. The team traveled 3500 miles through 15 states in 9 days and collected 3 terabytes of data from 20 active sensors. 99% of the distance they were in fully-automated mode.

The purpose of the trip was to compile data for different weather and traffic conditions to fine-tune sensor performance and vehicle algorithms. Owens reported that the trip exceeded all expectations. “It was the first time that anyone has driven coast to coast at the speed limit. We got a lot of gestures from drivers, especially as we got closer to the East Coast!” he said.

Six years ago, I drove across country in my trusty 2003 Volkswagen Golf – not at the speed limit. It took 4.5 days; 100% of the distance I was at the wheel. While none of us may be comfortable sleeping at the wheel while our car drives itself, it seems it could be a benefit, especially in long distance travel. Suddenly, the idea of autonomous vehicles didn’t seem so bad.

Signing off on the MEMS Conference 2015. ~ FvT