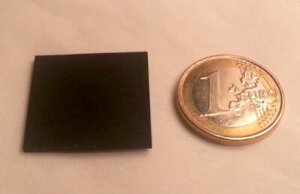

The 2.5D Interposer Module features three front-side interconnect layers of dual-damascene copper on top of a single-damascene copper metal layer, with 2µm Line/Space/Thickness interconnect dimensions. The via-first TSVs are copper-filled with a 10:1 aspect ratio and via-last TSVs are copper-lined, polyimide-filled with a 5:1 aspect ratio, both with 50µm pitch.

The 2.5D Interposer Module features three front-side interconnect layers of dual-damascene copper on top of a single-damascene copper metal layer, with 2µm Line/Space/Thickness interconnect dimensions. The via-first TSVs are copper-filled with a 10:1 aspect ratio and via-last TSVs are copper-lined, polyimide-filled with a 5:1 aspect ratio, both with 50µm pitch.

Testimonial

In addition to increased device performance, smaller form factor and lower power consumption, the silicon interposer product manufactured by Novati Technologies has other key benefits. It’s the only production interposer manufactured in the United States, particularly important to many defense contractors and government agencies. Novati’s ITAR-certified, 200mm and 300mm foundry in Austin, TX, performs extensive development work and advanced packaging for the DoD and other intelligence agencies who won’t send IP, components and technology off-shore. Novati expects to be a DMEA-accredited Trusted Foundry in summer 2014.

Future 2.5D/3D products under development incorporate integrated passive devices, CMOS image sensors (CIS) and several active interposers with wide I/O including memories, CPUs and logic, and enhancing our activity in 3D heterogeneous integration. The Novati fab specializes in More-than-Moore technologies and novel materials utilizing more than 60 elements (versus others’ limit of 25 elements) from the periodic table to provide unparalleled product solutions.

- Novati Technologies Website

- Date this Product was Introduced to the market: 1/20/2014

- Category Product is Being Nominated for: Devices

- Technical Information for Silicon Interposer Module