Everybody’s talking about reaching net-zero greenhouse gas emissions, but what does this actually entail? According to Pierre Farbos de Luzan, Henkel’s head of sustainability for electronics adhesives, the road to net-zero starts with raw materials.

To understand why, it’s important to touch on the different emission tiers – Scope 1, Scope 2, and Scope 3.

- Scope 1 emissions are created by a company itself. Any time a company generates direct greenhouse emissions from sources it owns, or controls are considered Scope 1 emissions.

- Scope 2 refers to indirect greenhouse gas emissions from the electricity that the company purchases. This could be the electricity for its IT infrastructure, electric vehicle charging stations, the lights in the building, and so forth.

- Scope 3 encompasses all other upstream and downstream direct greenhouse gas emissions generated by the supply chain. This is the largest emission category by far, encompassing every manufacturing process from all other suppliers, in addition to emissions caused by the product’s use and disposal. Scope 3 is also the most difficult for a company to control.

In 2022, the World Resources Institute reported that on average, Scope 3 accounts for 75% of company greenhouse gas emissions. However, this is only the average. In some cases, Scope 3 emissions can shoot above 99%.

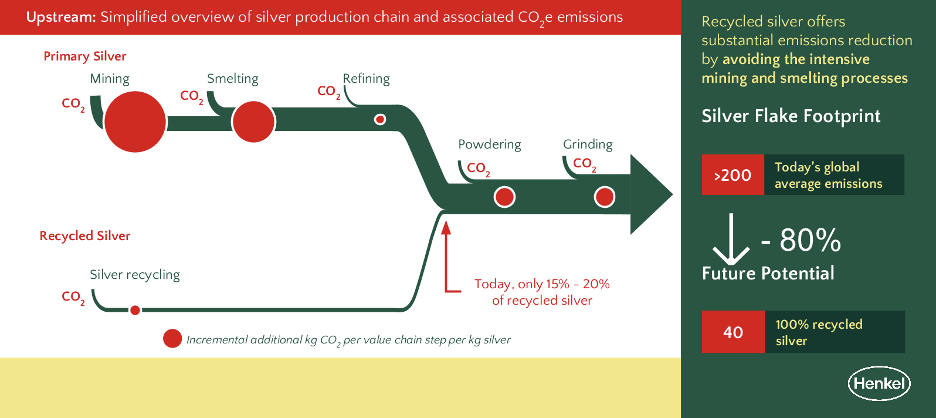

So, if the semiconductor industry wants to reach its net-zero goals, the biggest step it can take is to work with its suppliers to understand which raw materials produce the most emissions, because they aren’t all the same in terms of carbon footprint. For example, 1 kg of silver from a mine generates more than 200 kg of greenhouse gas emissions, while 1k of recycled silver only generates around 40 kg. But by using recycled silver, Farbos de Luzan emphasized that the industry can reduce this by 80% (Figure 1).

To achieve lower emissions, transparency across the value chain is required. This introduces its own set of challenges. While some suppliers are detailed about tracking their emissions, others don’t have the tools to calculate them. As a result, data availability and quality also impact a company’s ability to source low-emission raw materials. Getting the correct numbers to steer the right action is difficult, noted Farbos de Luzan.

“What you want are numbers that are as representative of your own supply chain as possible,” he said. “You either need to purchase them through a third-party database, get them from a supplier or even use proprietary tools to model them accurately.

Although buying third-party data is an option, Farbos de Luzan noted that it’s often not as accurate as getting the information straight from the supplier. For suppliers who don’t have this information on hand, Henkel helps bridge the gap through its Climate Connect program that trains suppliers on how to do this. While this is a noteworthy effort, Farbos de Luzan explained that it was inspired by insufficient emissions regulations.

“Adoption of low-emission raw materials is heavily influenced by regulation. Clear, consistent rules accelerate change, while uncertainty or weak enforcement slows it down,” he said. “Companies like Henkel drive this forward, but regulatory frameworks are still lacking to accelerate progress at scale.”

Another major hurdle is cost. Lower-emission raw materials often carry a premium due to additional R&D, processing and reformulation efforts, equipment modifications, or the need for audits, certification fees, and traceability systems to verify the origin and authenticity of the sustainable material. If the opportunity is there, but too few companies are willing to pay, it will take longer to reach the economies of scale needed to realize the switch. Cost hikes may also come from operational changes like switching equipment or updating capital expenditure priorities.

Although cost concerns won’t be mitigated overnight, one step forward is to highlight areas where low-emission prices are comparable to their higher-emission material counterparts. Renewable energy is one such example. As of 2023, 81% of utility-scale renewable power projects demonstrated lower electricity costs than fossil fuel alternatives, and this will continue to improve over time.

In the meantime, Henkel is taking a leading role in understanding and reducing raw material emissions. Its LOCTITE® HHD 3544F solution is the first bio-based polyurethane reactive hot melt structural adhesive with 60% bio-based raw material, resulting in >15% emission reduction when compared with a fossil-based equivalent. Similarly, its LOCTITE® ABLESTIK QMI519 conductive die attach can lower greenhouse gas emissions by more than 40%.

’We’ve started the journey and already offer low-emission raw materials and products to our customers, contributing directly to reducing their scope 3 emissions,” said Farbos de Luzan. “By purchasing from us, they can effectively improve their own emissions profiles and achieve their sustainability targets.”

Learn more about Henkel’s sustainability initiatives.