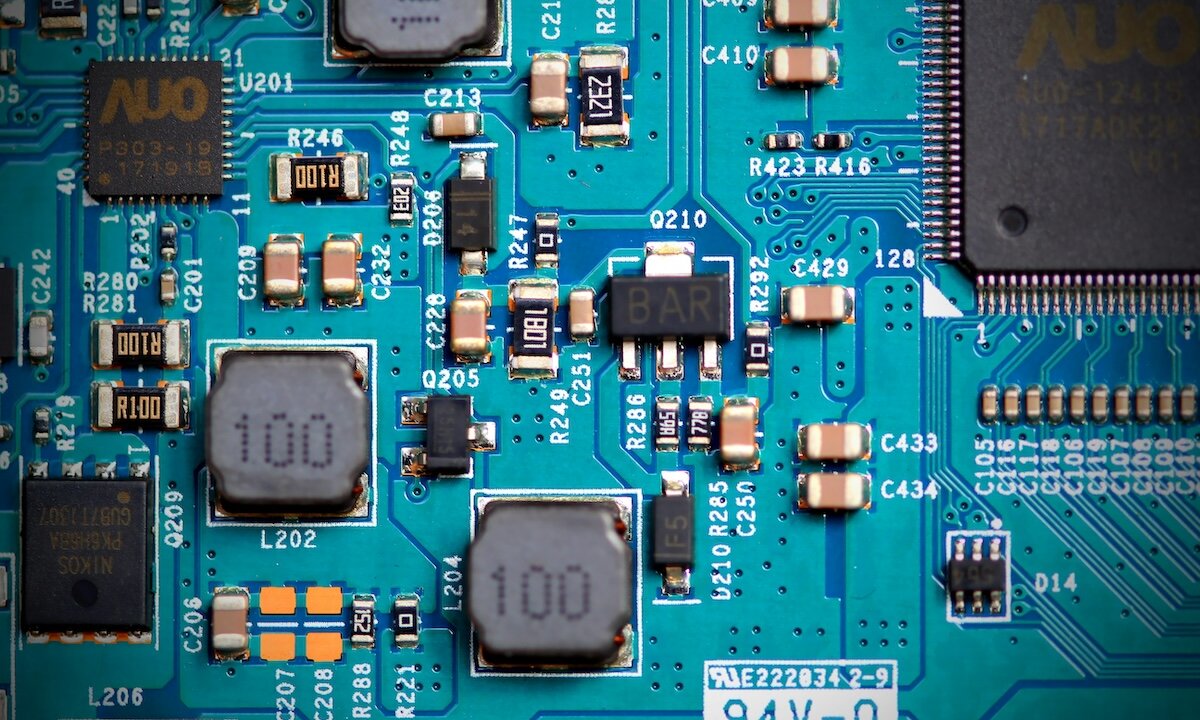

Indium Corporation, a leading materials refiner, smelter, manufacturer, and supplier, announced the global availability of SiPaste® C312HF, a halogen-free, cleanable solder paste formulated for fine-feature printing. Designed with Type 7 powder for aperture sizes down to 60μm, it enables fine-feature printing in advanced system-in-package applications.

SiPaste® C312HF boosts process yields that combine best-in-class stencil print transfer efficiency and excellent stencil life with consistent printing, excellent response-to-pause, and superior reflow performance. SiPaste® C312HF post-reflow flux residue can be cleaned with a standard cleaning process using semi-aqueous chemistries or a saponifier, or it can be used as a standard no-clean paste in processes where post-reflow cleaning is not required.

SiPaste® C312HF delivers several benefits to users, including:

- Consistent with low standard deviation solder deposit spread across multiple prints

- Outstanding slump resistance

- Low voiding across all components

- Optimized powder formulation and flux vehicle

- Requires minimal stencil cleaning during printing

- Wide reflow profile window

- Excellent wetting capability on various metallization

Indium Corporation’s SiPaste® series is specifically designed for fine-feature printing with fine powders ranging from Type 5 to Type 8, including the SiPaste® C312HF with Type 7 powder. The products help Avoid the Void®, reduce slumping, and demonstrate consistent superior printing performance.

To learn more about Indium Corporation’s semiconductor solder pastes, visit https://www.indium.com/products/solder-paste/semiconductor/.