The 54th Design Automation Conference (DAC 54) at the Austin Convention Center was very different, compared to the last several years’ events. Walking the exhibition floor, listening to keynotes, SKY talks and CEO interviews I got the following key impressions:

The 54th Design Automation Conference (DAC 54) at the Austin Convention Center was very different, compared to the last several years’ events. Walking the exhibition floor, listening to keynotes, SKY talks and CEO interviews I got the following key impressions:

While still representing a big part of the audience, the grey-haired men (like myself) were less dominant this year. Many younger people brought different [hair] colors to the conference and demonstrated that they are committed to carrying on the work of the now grey-haired generation.

In stark contrast to other conferences I attended in recent years, I found the keynotes and other sessions very solutions-minded. User benefits, the total cost of ownership (TCO), and return on investment (ROI) were central to these presentations. Above all, descriptions of system-level solutions by far outnumbered the references to component features. I really like this trend, away from a commodity and component-focused perspective, to higher-margin customer specific system solutions. Multi-die ICs (a.k.a system-in-packages (SiPs)) are and will be a key enabler to accelerate this trend.

However, besides these very positive trends, my friends and I had the impression that the number of attendees at the Austin Convention Center was lower than in previous years.

While many speakers emphasized that our focus on the Internet of things (IoT) opportunities will require significant changes in our semiconductor industry, they gave very few specifics about how and what to change.

Let’s substantiate these general statements with specific examples.

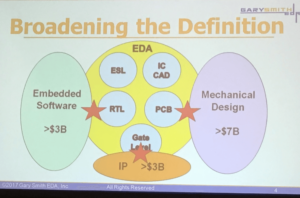

For me, DAC 54 started on Sunday evening with a presentation by Laurie Balch from Gary Smith EDA. Her key message was “Broadening the Definition” of the design space. Figure 1 below shows the key elements of a complete system design environment, as mechanical design also includes IC package and board topics.

Several exhibiting companies impressed visitors with very colorful and creative booth designs. In my opinion, OneSpin Solutions’ booth topped all others in this regard. (Figure 2).

Several exhibiting companies impressed visitors with very colorful and creative booth designs. In my opinion, OneSpin Solutions’ booth topped all others in this regard. (Figure 2).

Equally colorful and very focused on user benefits was Joe Costello’s keynote on Monday morning. In his “IoT: Tales from the front line” presentation, Costello, CEO of Enlighted, Inc., described how his company has developed and installs intelligent sensor networks to provide timely, accurate and actionable information about facilities’ utilization for a company’s management. Costello emphasized that IoT requirements, unlike highly standardized smartphones, are very diverse and demand unique and economical solutions for specific applications. He also gave additional examples how his company’s IoT solutions are being used for asset tracking, to initiate preventive maintenance and other purposes.

On Tuesday morning, Keynoter Chuck Grindstaff, executive chairman of Siemens’ PLM Software business unit, explained why his primarily mechanical CAD-focused team and Siemens’ top management decided to acquire Mentor Graphics. Mentor’s product portfolio is a valuable addition to Siemens’ strengths for bringing (operational technology (OT) and information technology (IT) closer together to offer more intelligent and complete system solutions. Grindstaff mentioned automotive, robotics, energy generation and distribution as examples for high growth markets and opportunities for jointly developed Siemens and Mentor solutions. He emphasized the need for change and new business models, to streamline the “Ideation – Realization – Utilization” process at Siemens and their customers and support the next generation workforce better. The slide below shows that Grindstaff believes in multi-die ICs, as means to move to system-level solutions. Figure 3 lists other companies that use IC design expertise to improve their system solutions.

After clearly conveying his vision for the success of Siemens and Mentor, Grindstaff offered his remaining time, about 15 minutes, to answer questions from the audience. After a slow start, because people didn’t expect such openness, several questions were raised. His answers showed that Siemens has clear and long-term plans for integrating Mentor’s capabilities into the corporation. Contrary to current rumors, Grindstaff stated that Siemens will not sell the Calibre team.

In the press briefing with Grindstaff and Rhines that followed his talk, we learned that Siemens initiated the discussion that led to this acquisition. Rhines and Grindstaff first got to know each other in 2008, when Mentor was looking for a White Knight to fend off an acquisition attempt from Cadence. Grindstaff also mentioned that mutual customers suggested Siemens acquire Mentor.

In the press briefing with Grindstaff and Rhines that followed his talk, we learned that Siemens initiated the discussion that led to this acquisition. Rhines and Grindstaff first got to know each other in 2008, when Mentor was looking for a White Knight to fend off an acquisition attempt from Cadence. Grindstaff also mentioned that mutual customers suggested Siemens acquire Mentor.

Ed Sperling managed an interesting SKY Talk on Tuesday afternoon (Figure 5). He interviewed Lucio Lanza and Simon Segars – joining via video link from Japan – about “exploring the connections between the digital world and physical world”. Both executives confirmed that many IoT designs are in progress and highlighted that the internet of millions of computers has been turned into the internet of billions of people and is expanding now into the internet of trillions of things.

Security was, of course, a major topic in this context. Segars mentioned the building blocks ARM/Softbank can offer their customers to make designs more secure. He and Lanza pointed out that customers’ willingness to pay for these security measures varies widely and increases significantly right after customers have experienced a security breach. Another security challenge we face is that hackers are getting smarter all the time, requiring more sophisticated countermeasures in this arms-race-like competition.

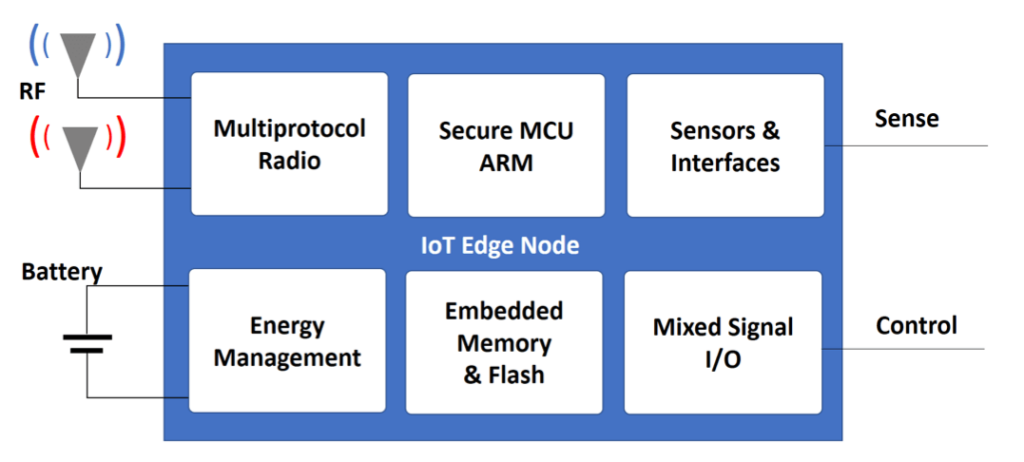

Tyson Tuttle, CEO of Silicon Labs, gave Wednesday’s keynote: “Accelerating the IoT”. Tuttle projected that today’s 20 billion IoT devices will grow to 70 billion by 2025 and the current four billion smartphones and two billion networked computers will grow to seven and four billion respectively. He pointed out that there is a big difference between developing and successfully deploying an IoT solution.

Tuttle warned that only well architected and feature-rich IoT designs will avoid the race to the bottom and will successfully compete with the lowest cost solutions. Hardware platforms, combined with application-specific software will enable differentiation (Figure 6). Quoting Darwin, Tuttle noted: “It is not the strongest that survives, nor the most intelligent. It is the one that is the most adaptable to change” and predicted that IoT will bring major changes to our work and leisure time and also will represent the biggest opportunity of our lifetime. As an example for a major change, Tuttle mentioned that 100 years ago 80% of our population were farm workers, while today it’s only 3%.

Thursday morning I skipped MIT’s Rosalind Picard’s keynote: “Emotion Technology, Wearables, and Surprises” to attend a training session on Mentor’s recently announced “Die – Package – Board” co-design flow. While friends pointed out that I missed a very interesting talk, I found Mentor’s training session even more interesting and very useful for my role as “Multi-die IC Evangelist”.

The training started with a brief introduction by Keith Felton, Product Marketing Manager at Mentor, a Siemens business. Dick James, Senior Fellow/Technology Analyst at Siliconics, in his role as a consultant to TechSearch International, gave an IC packaging market overview, explained the differences between the many packaging technologies and set the stage for the following in-depth technical presentations by Amkor and Mentor.

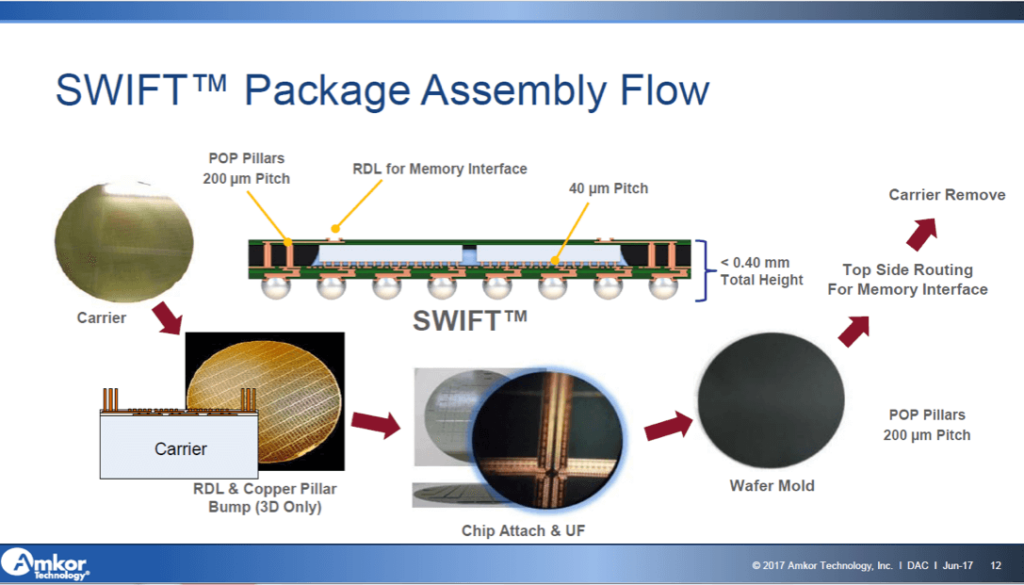

Suresh Jayaraman, Senior Director Advanced Package & Technology Integration at Amkor, Mentor’s first OSAT Alliance partner, outlined their cooperation with Mentor to develop design kits, then focused on explaining the benefits of Amkor’s silicon wafer integrated fan-out technology (SWIFT™) package: Very thin profile, good electrical and thermal performance, fine pitch routing, lower cost alternative to interposer-based (2.5D) designs (Figure 7).

Jayaraman concluded his presentation with a few slides about Amkor’s recent Nanium acquisition. Figure 8 compares Amkor and Nanium.

The next speaker, Kevin Rinebold, Principal Packaging Applications Consultant at Mentor, presented in great depth Mentor’s Die – Package – Board design flow, explained individual steps, data formats deployed and modeling support available. Rinebold’s long and in-depth technical presentation will be the topic of a separate blog soon. To visualize the power of the flow Rinebold explained, Ian Gabbitas, Packaging Application Consultant, demonstrated the Xpedition Substrate Integrator with the example in Figure 9 below.

Just a few closing comments: I like Austin, it’s modern convention center and its professional staff. What I didn’t like that much – and there isn’t anybody to blame for it – was the extreme Summer heat, of almost 100ºF. Even worse, a quick stop in Phoenix on my way back exposed me to 111°. Having said this, I look forward to DAC 2018, because it will be in San Francisco, only 40 miles from my office. The outside temperatures will be around 70 oF. Lots of news about multi-die ICs modeling, design and verification, die – package – board co-design and system scaling will certainly be on the agenda because high-density advanced packaging solutions will enable many more system-level solutions in the coming 12 months. I look forward to meeting you at DAC 2018 in San Francisco, end of June. ~ Herb