The brainchild of Joe Fjeldstad, Verdant Electronics, Occam Process got a lot of ink in the press when it was first introduced in 2007. I should know. I recruited several articles from Fjelstad myself for publication in Advanced Packaging Magazine. During an advisory board luncheon at SEMICON West, Fjelstad sidelined me to tell me about the 3D assembly process, which involves a reverse-order interconnect process implemented using existing materials and equipment, resulting a solder-free assembly that is said to achieve such high reliability that Fjelstad jokes about it passing a “throw test” rather than a “drop test.”

Since the initial media frenzy that occurred as all the electronics assembly and packaging publications scrambled to be the “first” or the most “in depth” or even the “most controversial” sources of coverage, Occam has faded from the press limelight. However lack of coverage doesn’t necessarily mean lack of progress, and recent correspondence I received from Harvey Miller, of IEEE, brought Occam duly back on my 3D radar. He shared an article he wrote for PCBOO7, which thoroughly explains what Occam is and what it isn’t, and why Miller endorses Occam as having “the potential to transform electronic manufacturing and restore the competitive position of U.S. and North America as creators of real value.”

I caught up with Fjelstad yesterday. He told me that concepts are beginning to evolve, and pointed out several particularly active areas of interest. “Nacent projects are underway with the Navy,” he said. “They are beginning to develop their own assembly processes based on Occam.” The second area of “burgeoning interest” is in LED lighting. Lead-free materials are an issue with lighting assemblies, because the temperatures are too high, so solder assemblies are running into problems.  The solder-free aspect of the Occam prcess makes it a perfect technology for lighting. Interest is also heating up in the automotive industry.

The solder-free aspect of the Occam prcess makes it a perfect technology for lighting. Interest is also heating up in the automotive industry.

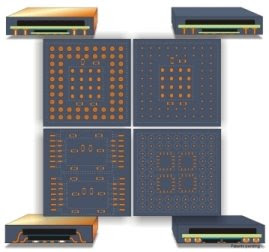

In semiconductor packaging, the Occam Process allows for an innovative 3D stacked package configuration Fjelstad refers to as package-under-package (PuP). “There is possibility to take existing packages and affix one beneath the other creating a PuP and presenting them for assembly using standard SMT processing.” He explained. The module examples shown here include ability to provide metal jackets for shielding and thermal relief.

If the amount of interest can be measured in requests for presentations and keynote addresses, then things are looking good for the future of Occam. ”I gave a presentation yesterday to a room full of top-level technologists from top-tier companies and got a good deal of head nodding during my talk,” noted Fjelstad. “It has wings of its own.” Here’s to a successful flight. – F.v.T.