Accomplishment

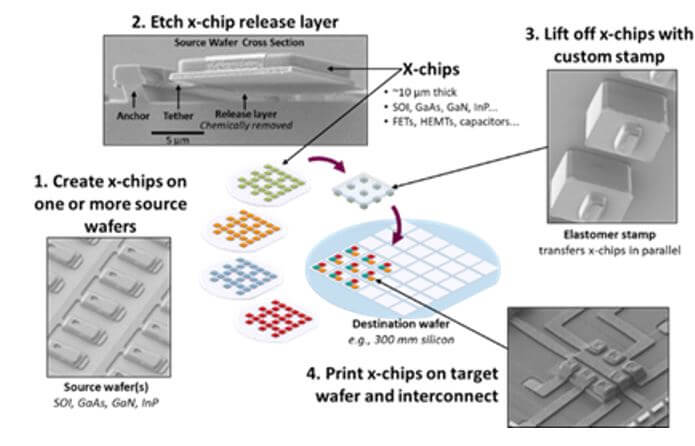

Analog semiconductors require 3D heterogeneous integration of diverse components to improve performance & functionality, including HEMTs, HBTs, power transistors, gate drivers, photonics, sensors, hardware assurance, capacitors, inductors, filters, & antennas made using different process nodes & technologies, including SOI, GaAs, GaN, InP, & SiGe. X-Celeprint’s micro-transfer printing (MTP) technology uses a massively parallel pick-&-place process to stack large arrays of ultra-thin (1-20µm) diverse components (x-chips) from separately manufactured wafers on a variety of destination substrates to achieve heterogeneous integration, creating a 3D IC with improvements in performance, power, density, cost, & time-to-market. ASM AMICRA supplies precision placement systems to implement X-Celeprint’s MTP technology, and X-FAB, the leading foundry for analog/mixed-signal semiconductor solutions, has licensed X-Celeprint’s MTP technology to support volume heterogeneous integration.