Accomplishment

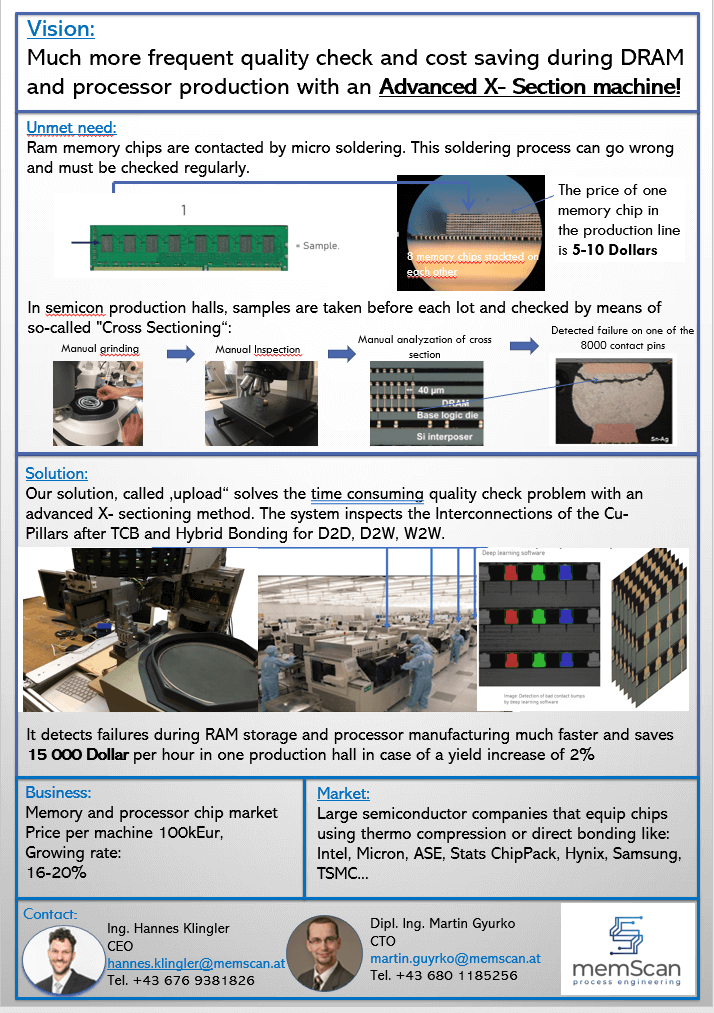

memScan OG develops and builds a machine for quality control of boards. This machine automatically and continuously takes samples of assembled circuit boards after TCB, Hybrid Bonding, D2D, D2W, W2W, releases the interconnects through grinding processes, takes up digital images of the Cu-Pillars and examines them with AI-assisted image processing. In a large production factory of memory boards with 20% of the world's production, €15,000 waste per hour is produced. The aim is to reduce this waste by means of regular, fully automatic quality checks of samples.

Potential customers are, on the one hand, production companies that produce memory and processor modules or other semiconductor packages in large quantities. Currently, manual cuts are created and visually analyzed randomly after TCB. It is known that this semi-automatic grinding image control is carried out at a large DDRAM storage manufacturer in Taiwan before each lot to keep the production yield loss under control.