Sometimes 3D IC/TSV news comes in with a splash on the front page of the morning paper, maybe somewhere above the fold, and sometimes 3D IC/TSV news comes in on stealthier feet, when a page is turned to reveal just what it is certain start-up companies have been doing all along with though silicon via (TSV) technology in their product architecture. Such is the case with Sand 9, a company that maybe not yet on the standard 3D IC/TSV radar, at least for now, but one sure to be soon.

Sometimes 3D IC/TSV news comes in with a splash on the front page of the morning paper, maybe somewhere above the fold, and sometimes 3D IC/TSV news comes in on stealthier feet, when a page is turned to reveal just what it is certain start-up companies have been doing all along with though silicon via (TSV) technology in their product architecture. Such is the case with Sand 9, a company that maybe not yet on the standard 3D IC/TSV radar, at least for now, but one sure to be soon.

Founded in 2007 in Cambridge, MA, Sand 9 claims to be “the technology leader in precision MEMS timing. Targeting a $4+B market opportunity with its piezoelectric MEMS products—which clock wireless and wired systems in mobile, low power wireless, communications infrastructure, industrial and military markets—Sand 9 outperforms both legacy quartz timing devices and other MEMS-based solutions. Sand 9’s MEMS timing products enhance quality and performance, simplify system design, and promote space and power savings in integrated electronic systems.”

Vincent Graziani, Sand 9’s CEO and president; and Alan Mond, executive vice president, sales & marketing; had great things to say about Sand 9’s business picture and technology, including their 3D IC/TSV technology, when we sat down together during the recent MEMS Executive Congress 2013, which was held at the Meritage Resort in Napa, CA, on November 7 and 8 2013.

A word first about the MEMS Executive Congress: the MEMS Industry Group (MIG), has been convening these executive congresses for its members and interested guests for about ten years now; the 2013 installment was the biggest and best MEC ever, with something like 280 attendees, and keynote talks from Gregg Bartlett, the senior vice president and CTO at GLOBALFOUNDRIES, and Donald Jones, VP, Global Strategy & Market Development at Qualcomm Life.

A word first about the MEMS Executive Congress: the MEMS Industry Group (MIG), has been convening these executive congresses for its members and interested guests for about ten years now; the 2013 installment was the biggest and best MEC ever, with something like 280 attendees, and keynote talks from Gregg Bartlett, the senior vice president and CTO at GLOBALFOUNDRIES, and Donald Jones, VP, Global Strategy & Market Development at Qualcomm Life.

That would be one of the world’s leading semiconductor foundries, and one of the world’s highest market cap semiconductor companies, presenting keynotes at the MEMS Executive Congress, to put into perspective just how much the MEMS industry has grown in recent years, and just how important the MEMS market has become, now that we are on the edge of the Internet of Things (IoT) era; an era that will be hastened along by something Sand 9 is aiming to do: enable the IoT by providing low-power MEMS timing solutions that are 50% smaller than quartz-based timing technology to facilitate wireless connectivity everywhere.

According to Vince and Alan, the precision timing market, which ships something like 10B units per year, has been based on quartz crystal technology for better than 50 years. If you take a look, you will see quartz timing products just about everywhere.

In general, precision timing devices, regardless of whether they are based on quartz or MEMS, generate a precisely timed clock signal, or “heartbeat” that sets the operating pace for microprocessors, micro-controllers, and System on Chip (SoC) components. Timing devices are also used to tune and maintain frequencies in TVs and cell phones, and to maintain timing and synchronization for various kinds of communications links.

Quartz technology has served the timing market well, but quartz timing products do have certain weaknesses—including device size, susceptibility to shock damage, and power consumption—that make MEMS-based precision timing products attractive in markets like mobile communication, which has pretty much been the beachhead market for most other consumer MEMS device applications to date.

(Just close your eyes and count the number of MEMS accelerometers, acoustic filters, microphones, gyroscopes, etc. currently in your iPhone or Samsung Galaxy; it’ll take the fingers of both hands to count if you have one of the current generation of smartphones.)

Sand 9’s MEMS timing devices are based on piezoelectric aluminum nitride, which is a thin film that is deposited using standard semiconductor/MEMS fabrication technology, using standard silicon wafers.

Sand 9’s MEMS timing devices are based on piezoelectric aluminum nitride, which is a thin film that is deposited using standard semiconductor/MEMS fabrication technology, using standard silicon wafers.

It’s been said many times “never bet against silicon” when comparing disparate microelectronic process technologies, and the case of silicon-based MEMS timing products against the quartz standard makes for an interesting comparison.

Vince and Alan say that the Sand 9 silicon MEMS products have advantages over quartz in terms of utilizing printed circuit board real estate (the MEMS products are smaller than the comparable quartz parts); the MEMS timing devices operate at lower power than does quartz, saving battery life; and the silicon-based MEMS parts can simplify system design, reduce part counts, simplify the supply chain, and improve manufacturing yields when compared to quartz.

High recommendations all.

Most MEMS devices travel in pairs with an accompanying application specific integrated circuit (ASIC). These ASICs are used to condition the MEMS device and to provide input and output functions, and are built using standard CMOS IC fabrication processes.

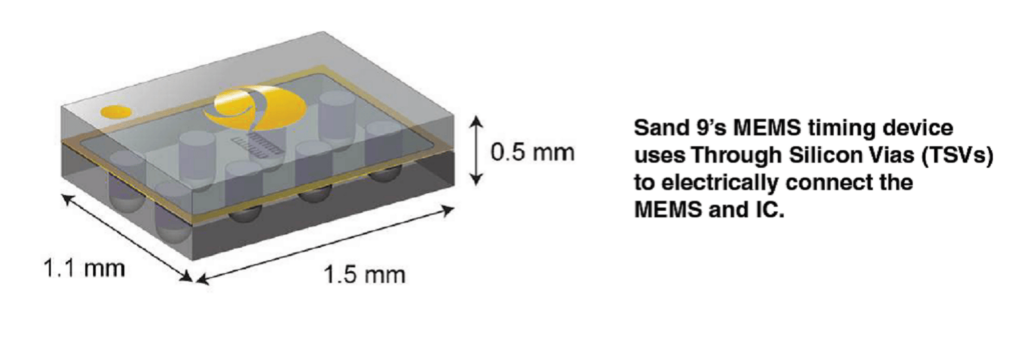

With both the MEM and the ASIC being made in silicon, it’s a natural next step to bond them together directly using TSV structures, which is what Sand 9 has done with its MEMS timing products.

With both the MEM and the ASIC being made in silicon, it’s a natural next step to bond them together directly using TSV structures, which is what Sand 9 has done with its MEMS timing products.

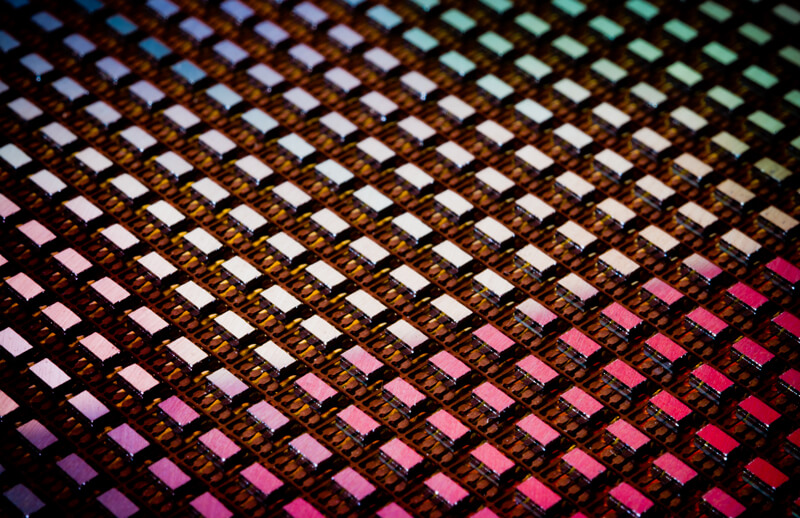

Sand 9 is a fabless MEMS company, and so has been using commercial MEMS foundries to fabricate their products. The commercial MEMS foundry process includes creating TSV structures as a standard process module; the Sand 9 fab work is currently being done by GLOBALFOUNDRIES, in Singapore, which is able to do something like 1,000 200mm wafers per month for Sand 9 products in a process that includes AlN deposition and polysilicon-filled TSVs. Alan and Vince report the Tier One foundry has been giving Sand 9 “superb support.”

The silicon MEMS precision timing device story at Sand 9 is so compelling that it’s attracted investments from Analog Devices (a MEMS pioneer), Intel Capital, and Khosla Ventures, among others. Those investments, together with the technical and commercial manufacturing volume capabilities of GLOBALFOUNDRIES, is a compelling story headed for Page 1.

Watch for more. From Petaluma, CA, thanks for reading. ~ PFW