Sustainability is rapidly taking center stage in most industries; the electronics and semiconductors space included. The major players in the electronics’ space — Alphabet, Apple, Amazon, Microsoft, and Facebook — have set aggressive carbon reduction goals for both themselves and their supply chain. These goals include having both themselves and their supply chains 100% powered by renewables as soon as 2030. These are admirable goals but are these companies also looking at conservation, and the circular economy of their products?

Bill Gates in his introduction to How To Avoid a Climate Disaster, states “Zero is what we need to aim for”, with respect to greenhouse gas emissions. I have attended a few conferences where I have heard the comment from large server companies: “Its ok if we keep increasing electricity consumption, as long as it’s renewable.” Or companies set up an e-waste recycling program, only to outsource the program and have most of the e-waste shipped overseas, thus kicking the can down the road. To really address the climate change issue in the electronics space, better conservation, as well as green energy sources, are needed.

A recent study by the University of Utah that was published in the journal Global Environmental Change, points out that in a consumer study both renewables and energy efficiency measures were effective in the fight against climate change, but in some sectors, it prompted the consumers to use more power. The authors highlight that it is important to change the consumer’s behavior to help facilitate change and that possibly will help with the conservation of energy.

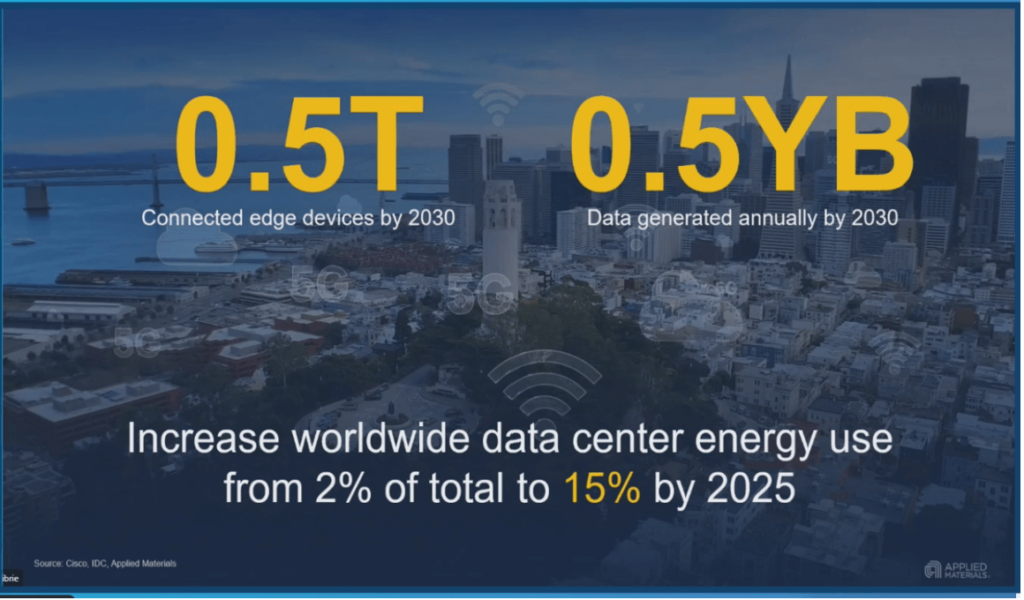

The semiconductor and electronics industries face a bit of a challenge. With the amount of data being generated and analyzed increasing to 0.5 Yottabytes by 2030, according to Chris Librie of Applied Materials, the energy use of data centers is expected to increase from 2% to 15% by 2025.

While it is expected that a significant amount of this increased power usage will be generated by renewables, this highlights the fact that energy consumption is increasing at a rapid rate, and there is the question of whether renewables and storage will be able to keep up with this torrid pace of consumption, or as suggested above, because we are using renewables we don’t need to conserve!

CEA-Leti to the Rescue

Fortunately, CEA-Leti has launched an ambitious proposal that hopes to improve energy efficiency in new microelectronic hardware and systems by a factor of 1000 by 2030. Announced on September 13, 2021, the proposal addresses nine research tracks that will look at both near-term and longer-term energy issues in the microelectronics industry. The proposal was presented in an 8-page paper that was given at the European Solid-State Device Research Conference (ESSDERC) and the European Solid-State Circuits Conference (ESSCIRC) in September. The author urges a systematic, green-tech approach of working simultaneously on five specific technology levels: process steps, circuits, architecture, software, and algorithms – while also pursuing nine research tracks. The paper, Overcoming the Data Deluge Challenges with Greener Electronics, does not question the industry’s ability to dramatically reduce its carbon footprint, but it notes the major challenges. These include opening the closed R&D culture, adopting new ways of thinking, and acting with urgency.

The program is broken down into nine research tracks that address:

- System usage and practices

- Circuit and architecture

- Semiconductor

and sets up a tentative timeline for the introduction of the solutions (Figure 2).

Figure 2: CEA-Leti proposal for electronics energy reduction (Source: CEA-Leti)

In the 2-3 year time frame we see proposals that are already in development and discussed at major electronics conferences. These include creating new systems using 3D technology such as interposers and chiplets to connect chips closer together to eliminate some of the energy used and generated using interconnects.

Intel, AMD, Nvidia, and companies that are building server farms, have and are creating a new generation of systems that will do a better job of crunching data. These systems in a package (SiPs) can be used at the edge in specific IoT applications. The challenge for the industry will be ensuring these systems reduce the amount of energy used to crunch data, and teach systems. Or is the industry just moving the data crunching from the server farms to the edge, thus shifting where and who consumes the energy in the data cycle? Edge compute, depending upon your definition, creates a distributed system so the power consumption is the same just more widely distributed, which doesn’t solve the energy consumption problem.

The 3-5 year horizon proposes some interesting possibilities. The Gate All Around(GAA), monolithic transistor construction, and SOI technology have the potential to reduce the power consumption in the transistor by the normal 20-30%, but historically there has been a power-performance trade-off. Gallium Nitride and Silicon Carbide have the potential to improve electron mobility and thus reduce power consumption, but we are early in the development process. The design of dedicated accelerators along with new algorithms has the potential to help improve the movement and analysis of data. I would expect as the industries’ understanding of how to manage data and its use in AI improve, it would potentially have a significant impact in reducing the energy needed to move data around the cloud.

In the 5-10 year horizon, sustainable electronics are part of the solution. I will be interested to see how business models change from introducing a new must-have product every 2 years that retires a previous product to a product that is designed to last five or more years and keep up with technology. E-waste and recycling programs will need to be developed to address the challenges. Julia Goldstein, a fellow blogger for 3D InCites, mentioned in a recent 3D InCites podcast episode, that there is more gold in a ton of e-waste than in a ton of gold ore. So it is economically feasible to set up domestic e-waste recycling programs to harvest precious metals, as well as plastics.

One of the points made in the CEA-Leti press release is that a radical change mindset is needed by the industry to implement the needed energy conservation and reduction of critical resources such as water. Radical change is something the semiconductor industry is not accustomed to. Processes and methodologies are typically set in stone. To change chemistry or chemical or even just a vendor takes months if not years of testing depending upon the status of the production process. Hopefully, with CEA-Leti and other organizations helping to drive and evaluate the change, the semiconductor industry can come together and move the needle a bit closer to zero in a timely manner.