In the USA, to motivate optimism when things haven’t turned out as expected, we say: “When life gives you lemons, make lemonade!” In other words, take the sour stuff, and find a way to make it sweet. In the MEMS business, we make lemonade all the time.

Every fab engineer has experienced the horror of an important wafer emerging from a chamber cracked. It’s the last device wafer! It’ll take weeks to get new wafers to the same point in the process! What now?

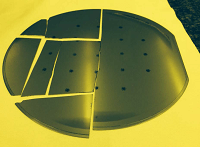

In Dr. Carolyn White’s recent presentation at EVG Technology Day, she explained how we make lemonade when things don’t go as expected in a new process. In prototyping, often the most valuable output from a wafer run is not the device itself, but the process data and tolerances which inform the next design or process revision. When faced with a broken wafer, we examine each fragment to see what may be salvaged. Since AMFitzgerald works in a development laboratory, we have access to equipment that can accommodate pieces as well as whole wafers. Often, we can continue to process the fragment, or do enough analysis or testing to harvest the valuable data we’re seeking.

MEMS manufacturers regularly make lemonade, too. MEMS processing is complex and full of variances: within the wafer, wafer-to-wafer, and lot-to-lot. Although chips may appear to be patterned and processed identically, they never come out all the same. Finished wafers often have beautiful chips in their center and duds at their perimeter.

Long ago, our semiconductor colleagues figured out how to manage the variety of lemons that inevitably come out of a complex silicon process. It’s called “binning“. All the chips on a finished wafer get probed, and the ones that meet all specs are put in one bin, and sell for the highest price, the ones that are not as good go in a different bin and sell for slightly less, and so on, until all the chips have been sorted. For decades, microprocessors, memory chips, and now MEMS resonators, accelerometers, and gyroscopes have all been sorted, binned, and sold in this way. (Sometimes, these small variances in chip performance may also uniquely identify an individual chip.)

The difference between a “performance” chip and a “consumer grade” chip is often not due to the design, but to where the chip had been located on its wafer.

Lemonade, anyone?

This post originally appeared in the March issue of the AMFitzgerald Newsletter, and was republished with permission.