Product Description:

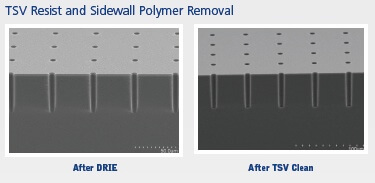

Post DRIE etch TSV cleaning is essential to the reliability of 2.5D and 3D IC devices. SSEC’s proprietary soak and spray technology minimizes spray time and chemistry use for lower cost-of-ownership than conventional wet bench or single spray approaches; it achieved 100% photoresist and sidewall fluoropolymer removal 5x faster than spray only.

Testimonial:

Improved yields and lower cost-of-ownership is the mantra for 2.5D and 3D IC commercialization. TSV clean, often overlooked as a critical process step, is essential to reliability. The DRIE etch process leaves behind a polymer residue that can lead to defects and voids in the barrier, seed, and fill steps that follow. SSEC’s 3300 Series for TSV Clean is proven to remove residues that wet bench-only or spray-only leave behind. The tool features equal-time soak software for process control. Each wafer soaks in heated, recirculating solvent long enough to penetrate the polymer residue. Following wet transfer to the spray station, the wafer is subject to a high-pressure spray to rapidly remove remaining residue. The result is 100% photoresist and polymer removal. Soak and spray takes 88% less time and 77.5% less chemistry than spray-only processes. The end result? Improved yields at lower cost-of-ownership.

- SSEC Website

- Date Product was introduced to the market: June 1, 2012

- Category Product is being Nominated for: Manufacturing Equipment

- Technical Information for the SSEC 3300 Series for TSV Clean